Thank you everybody !

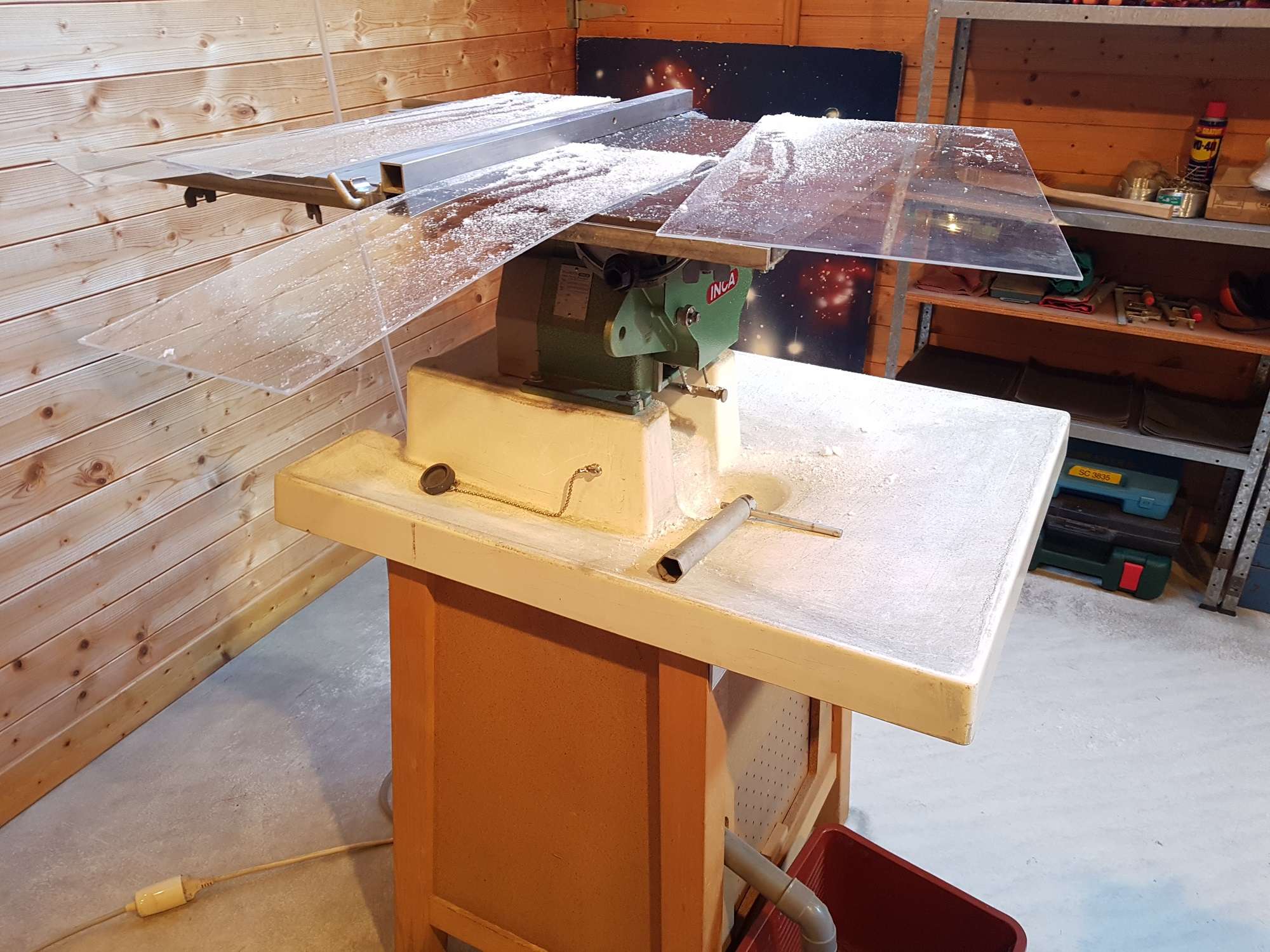

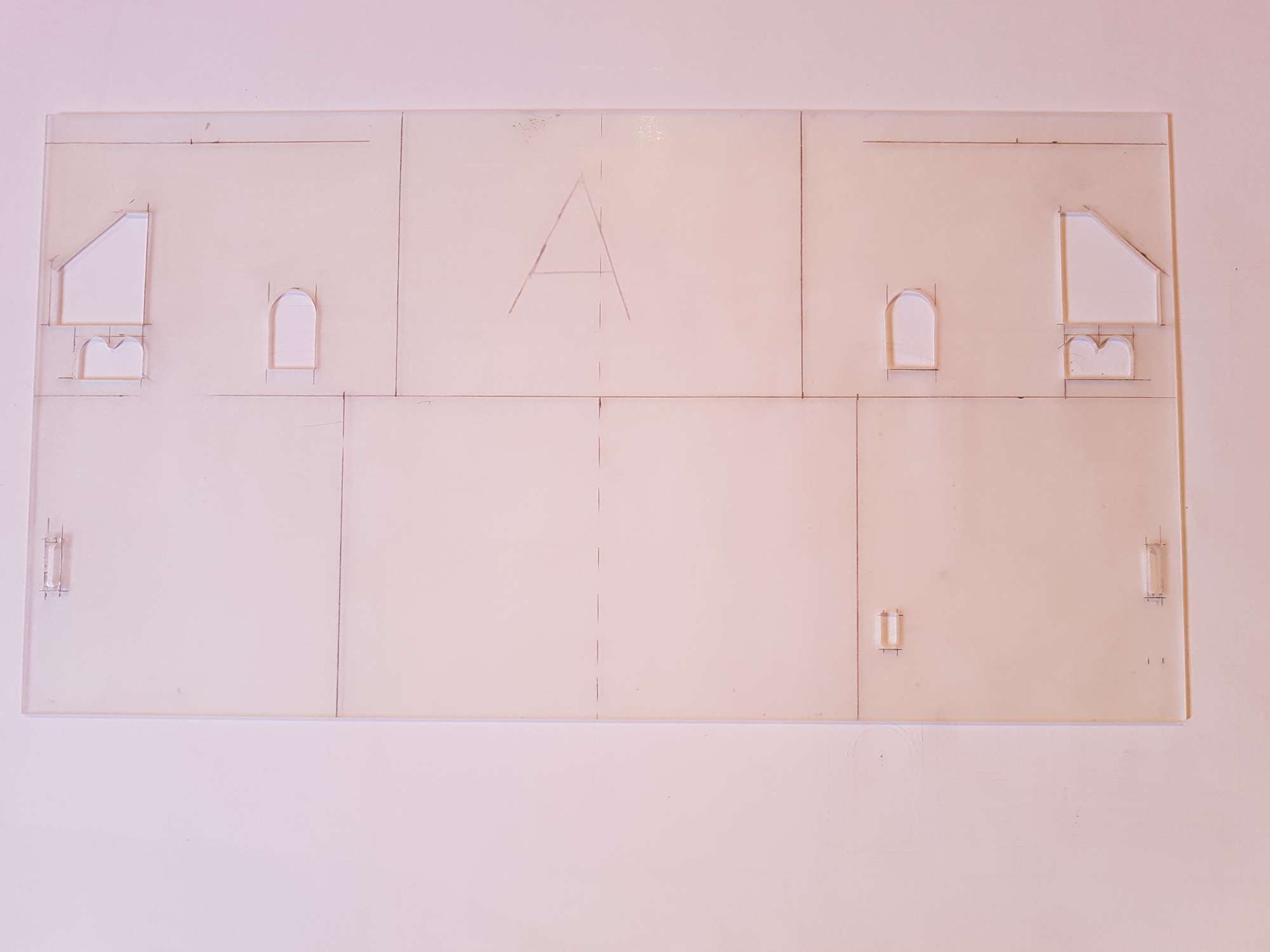

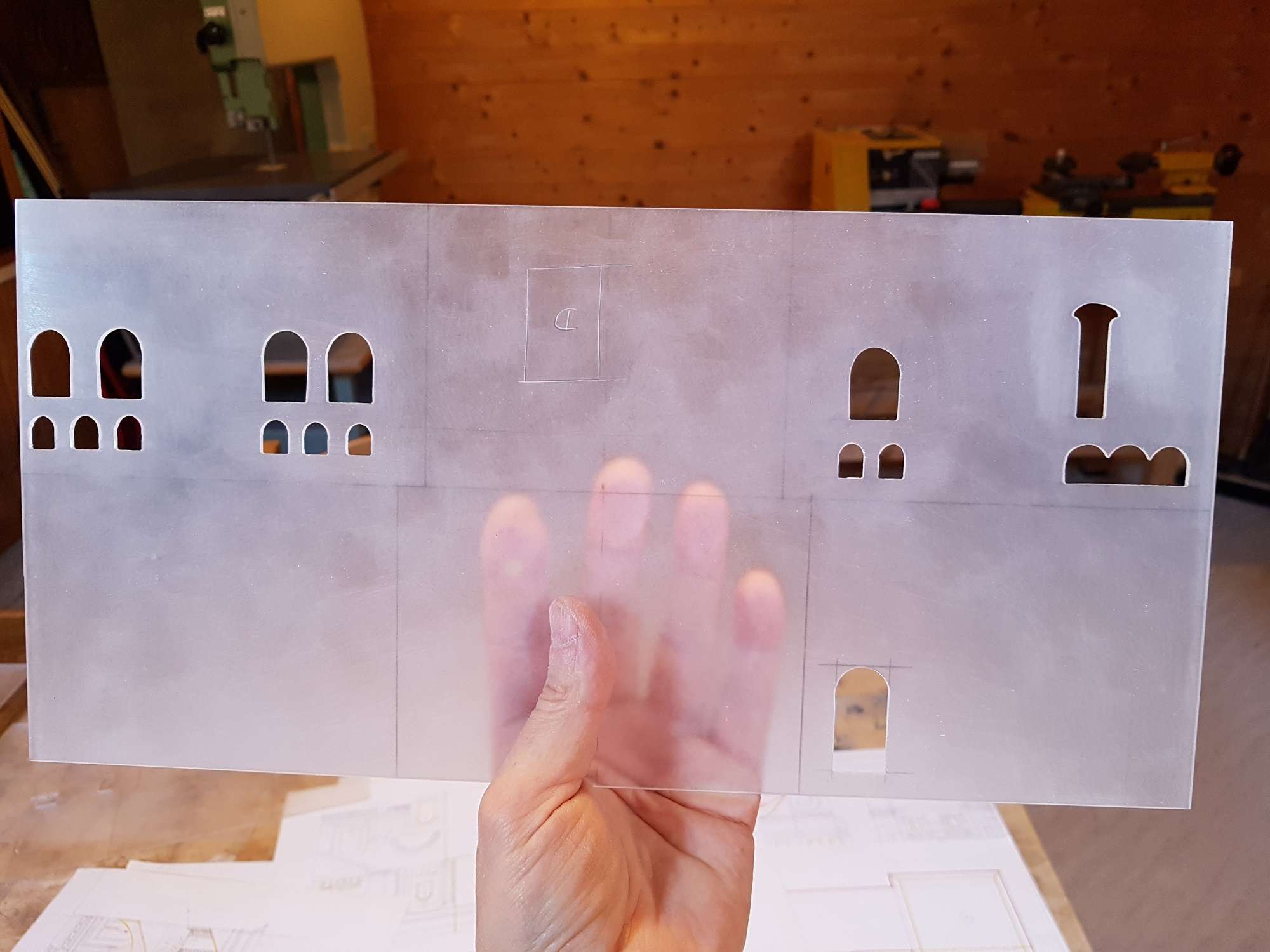

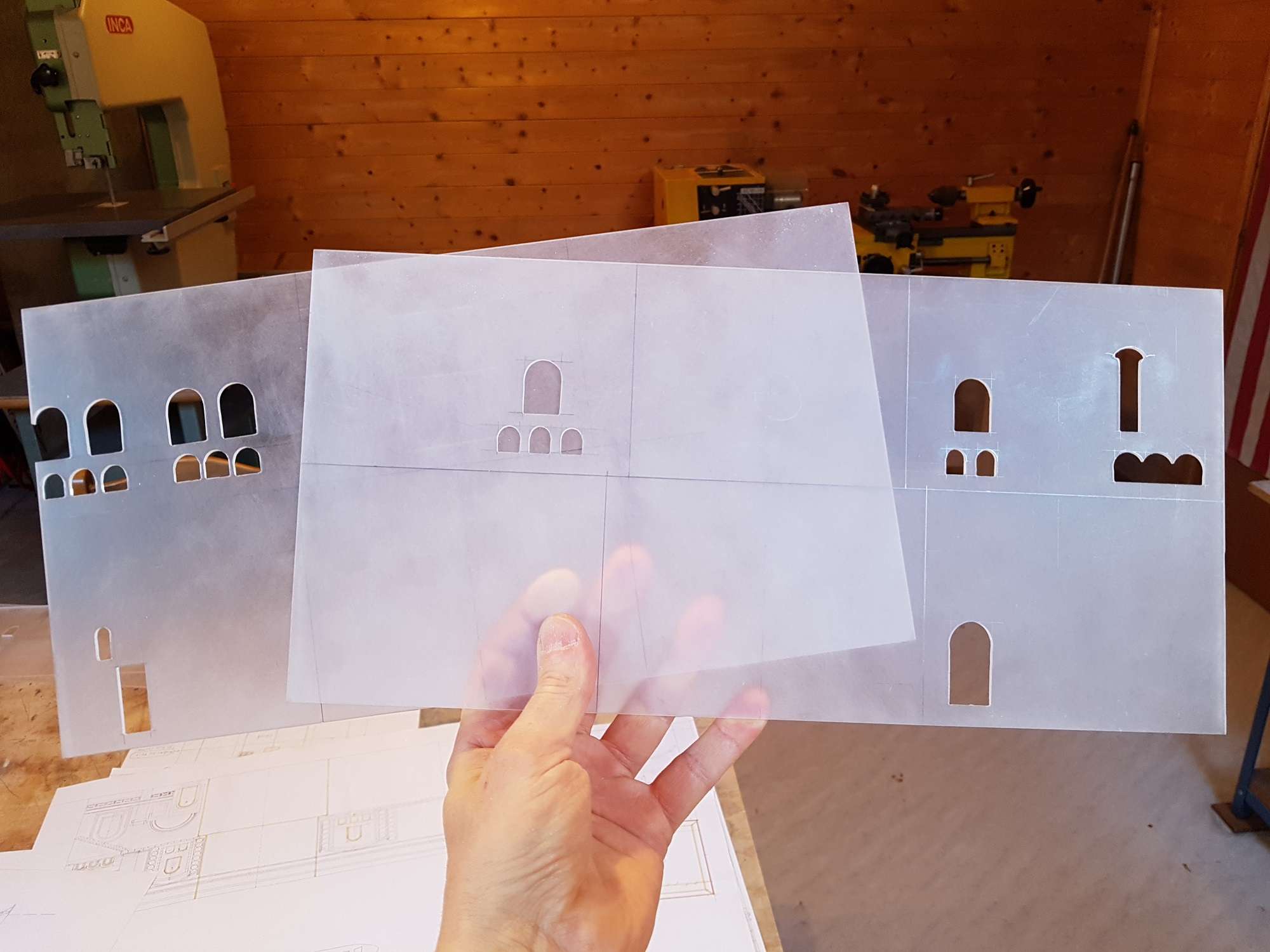

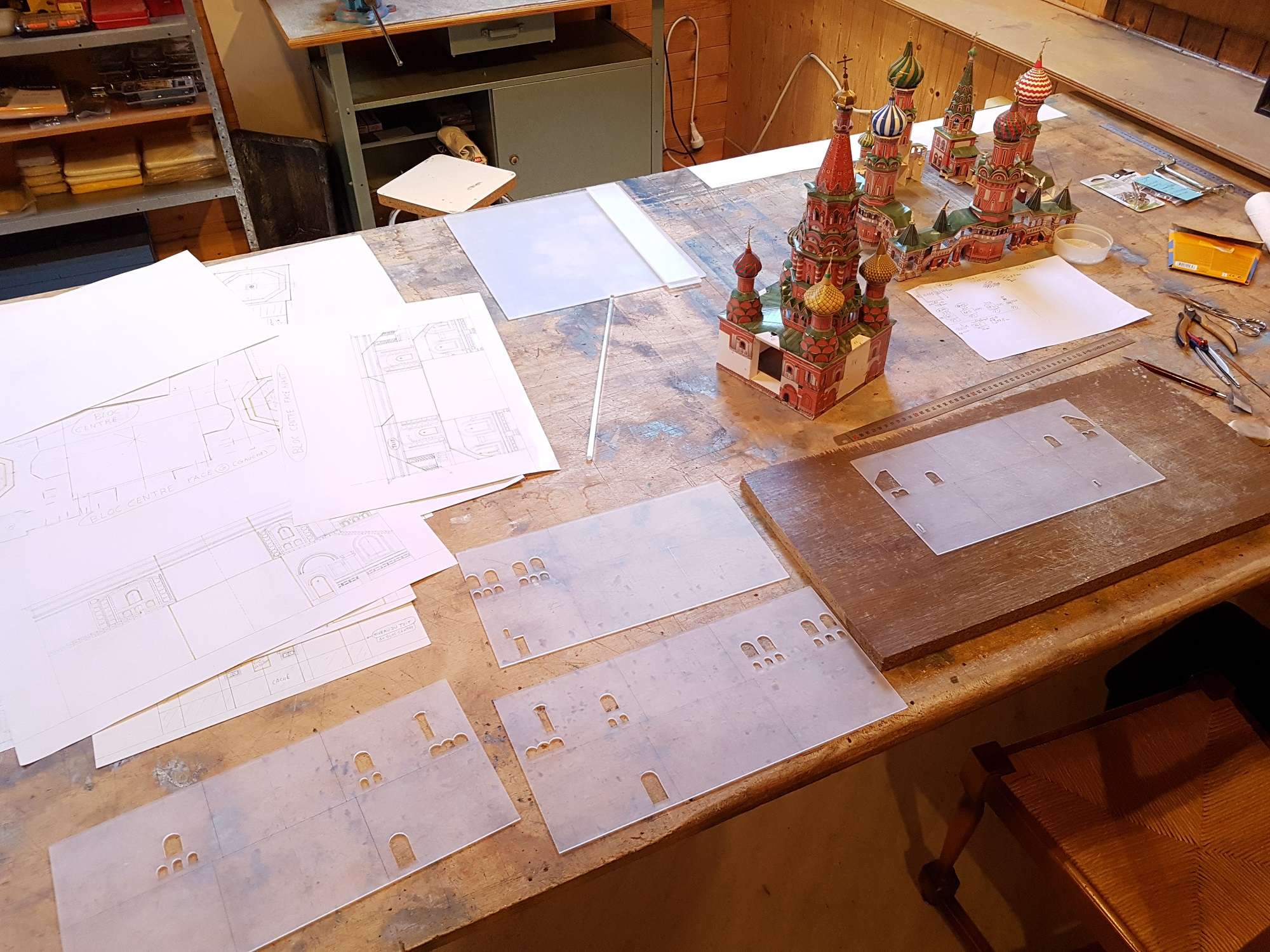

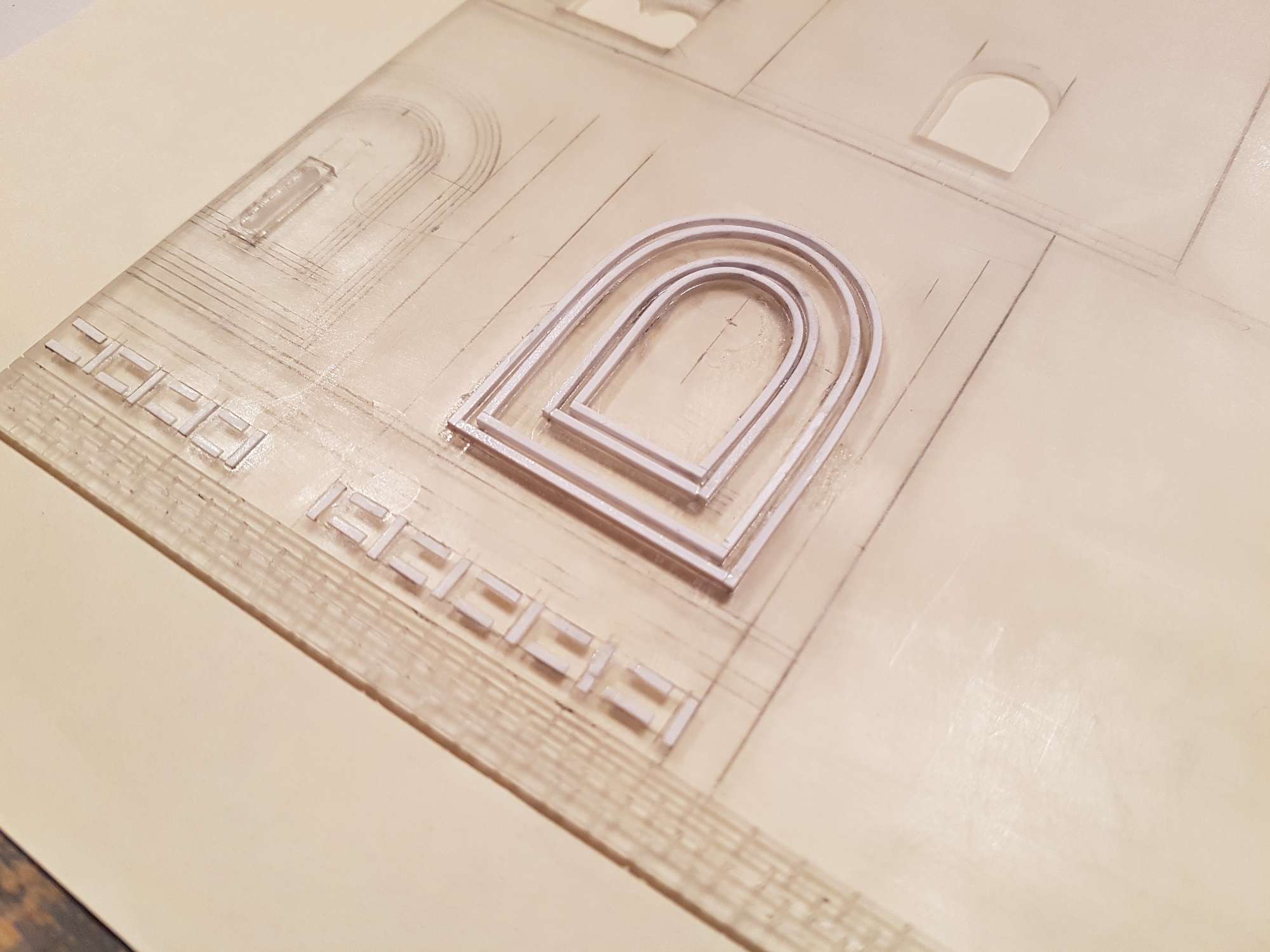

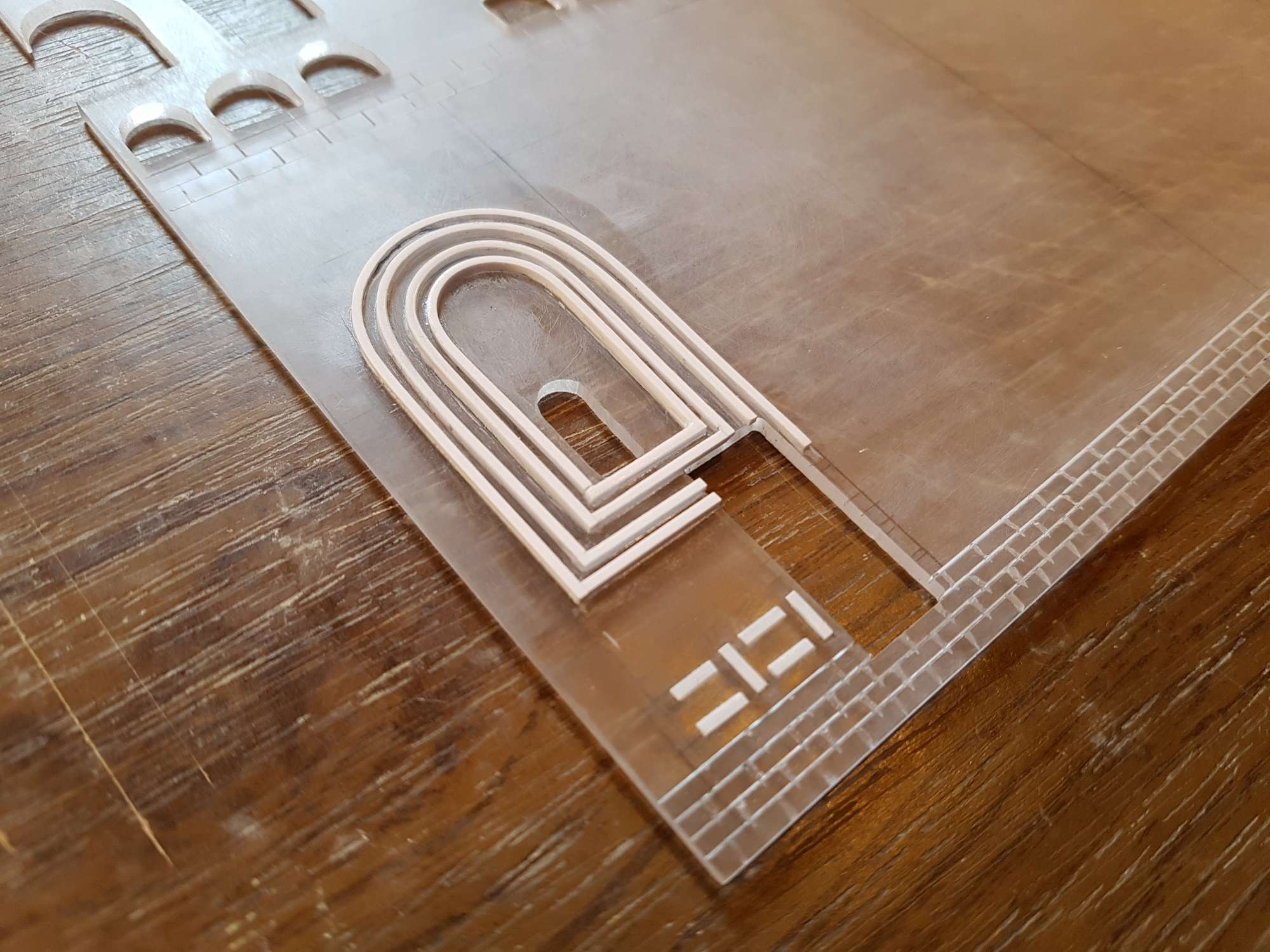

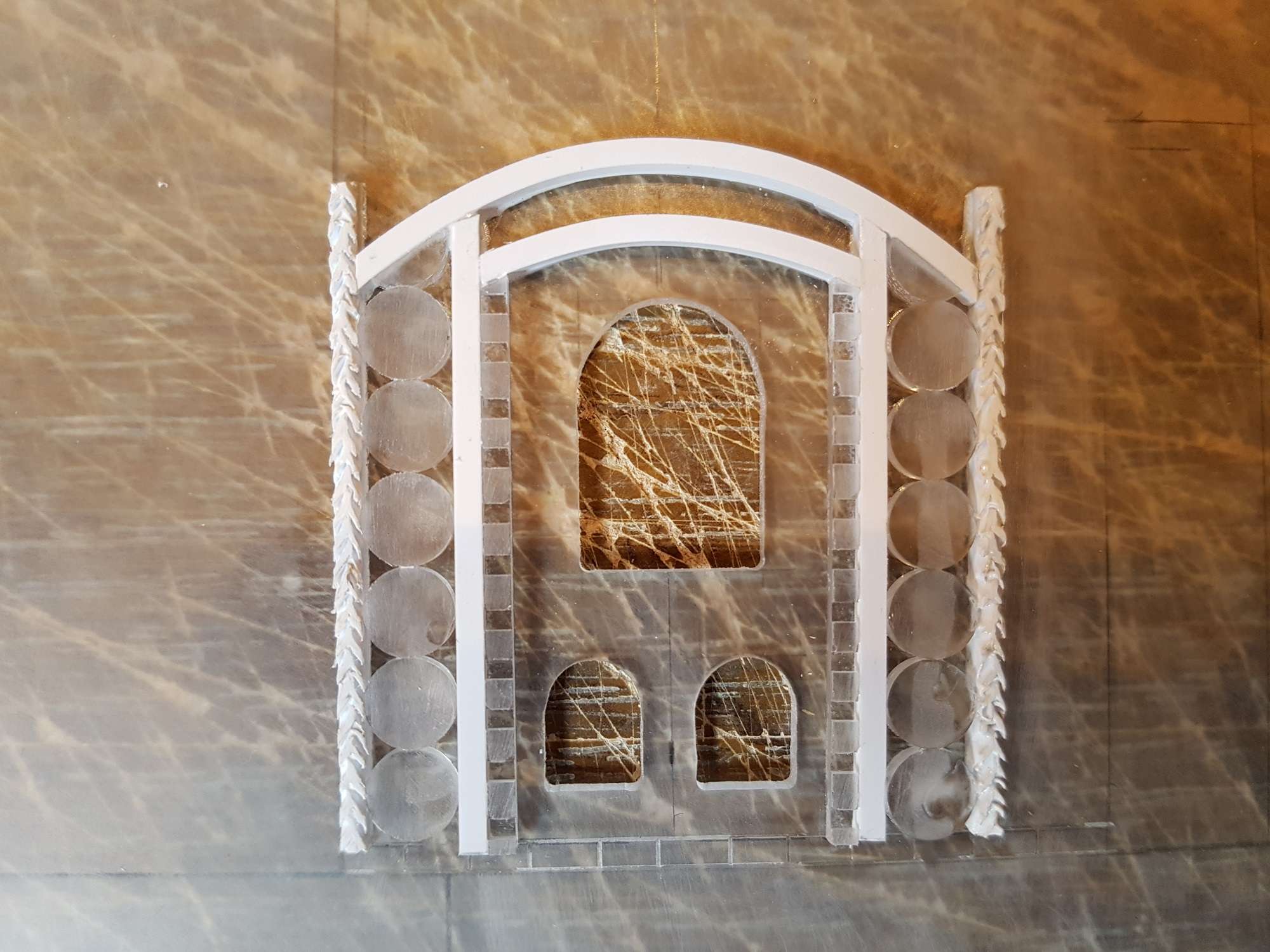

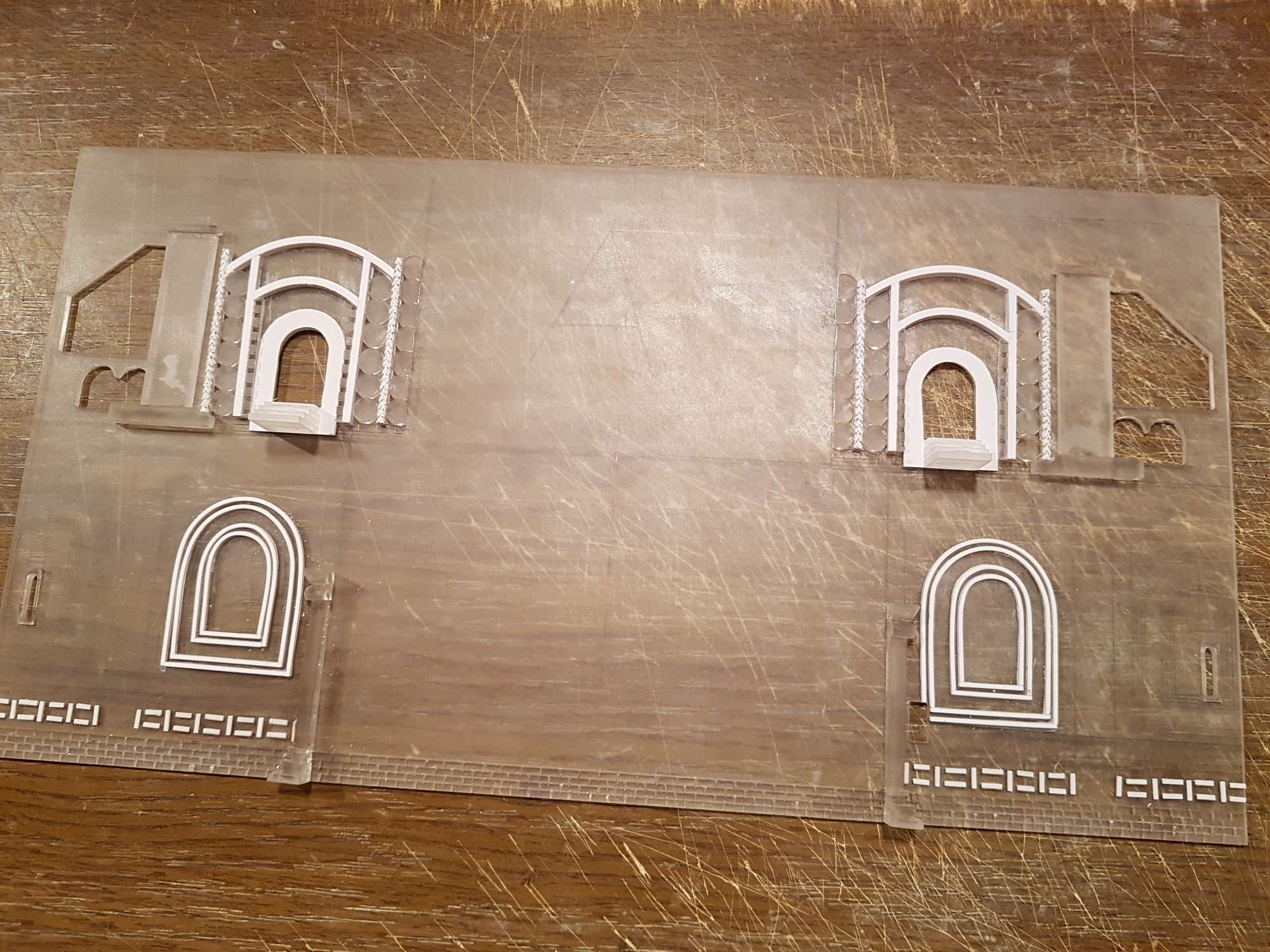

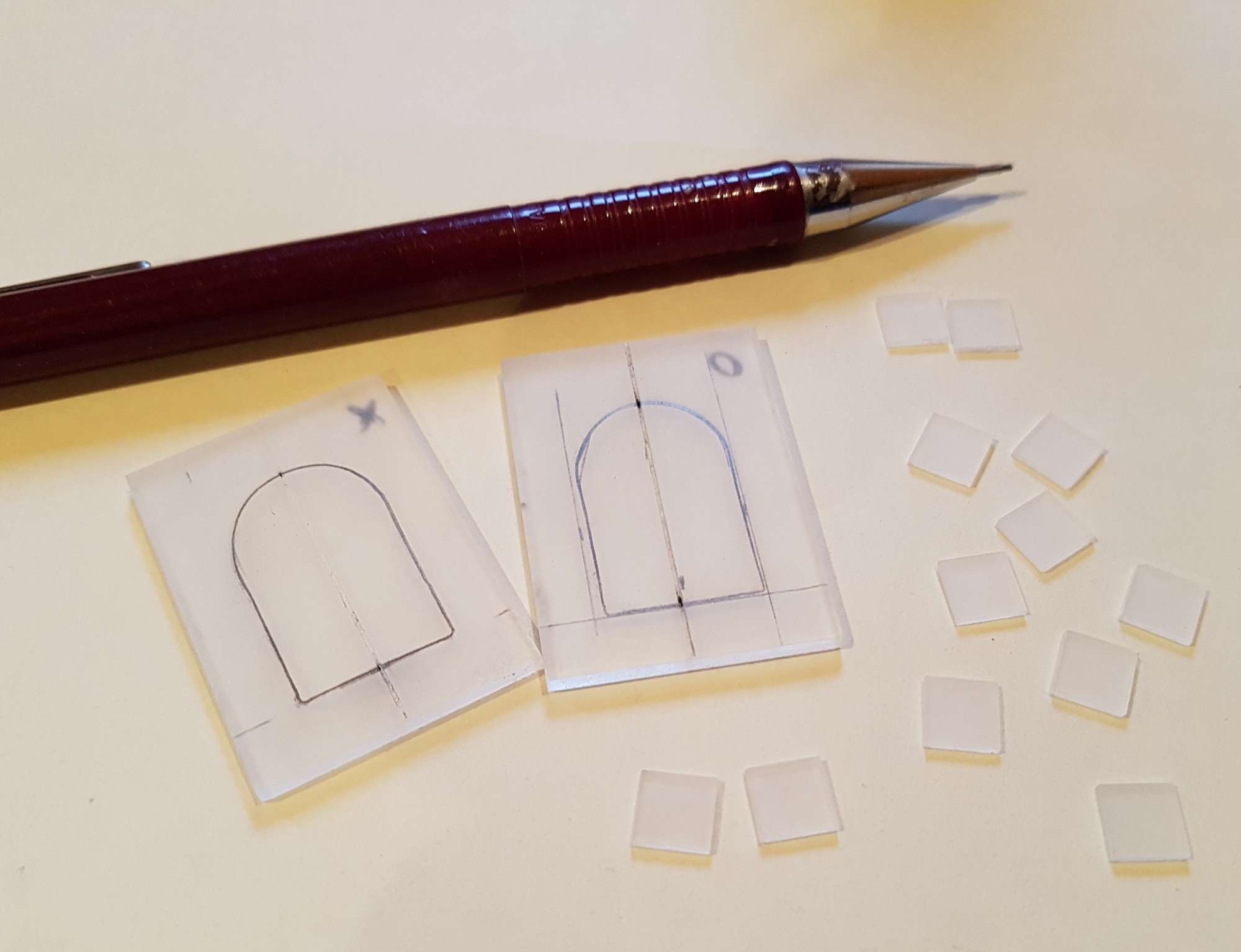

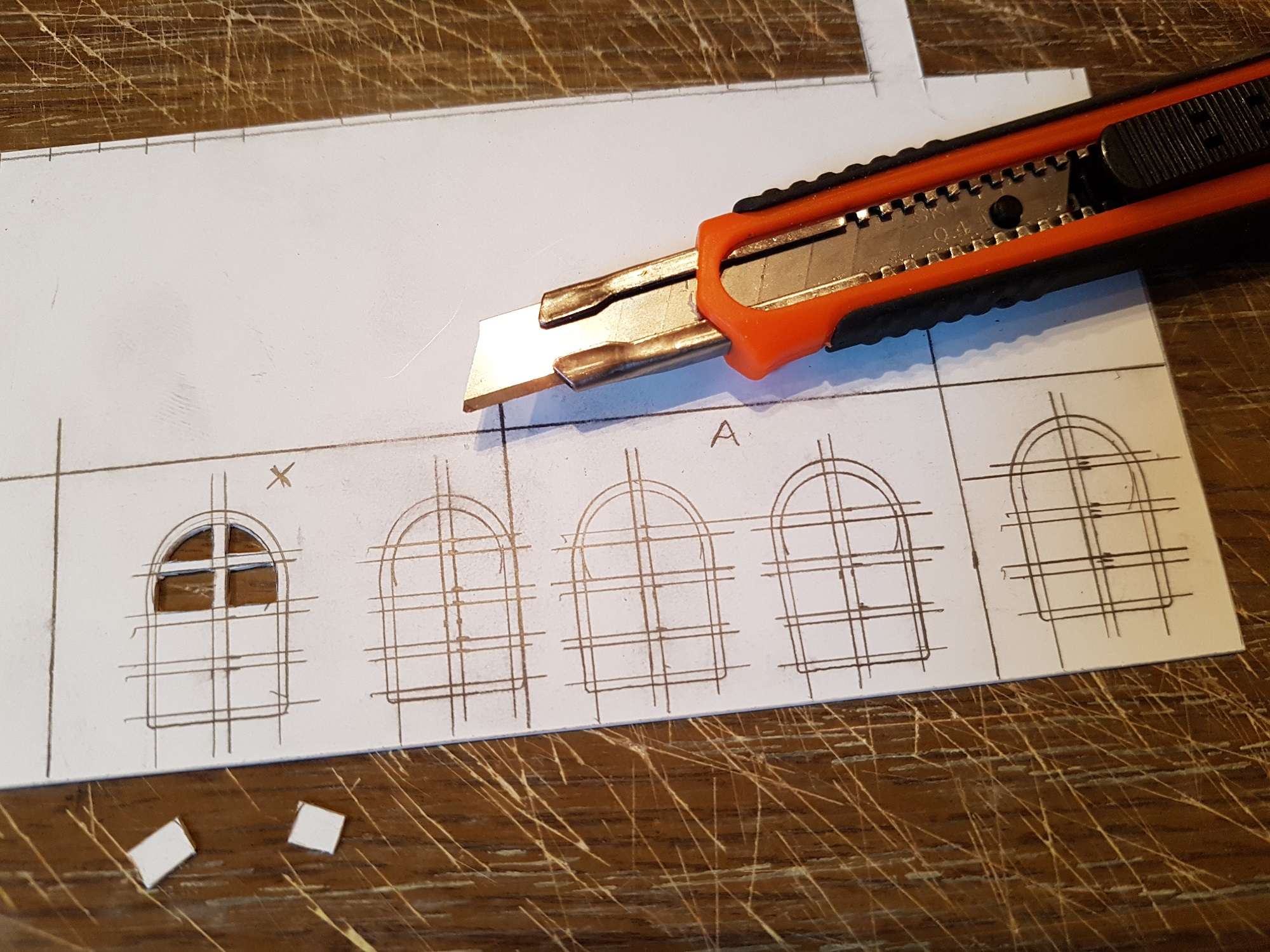

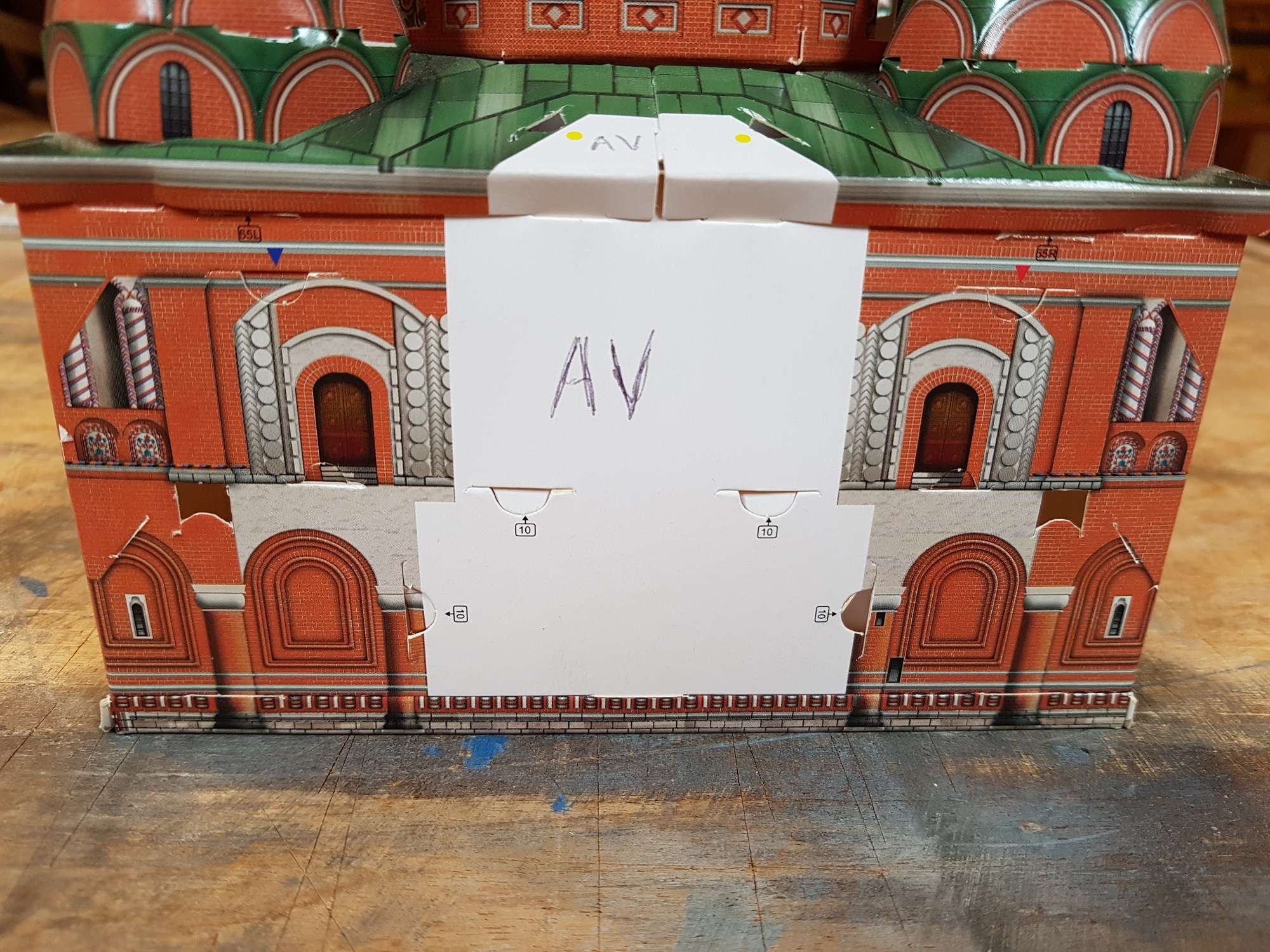

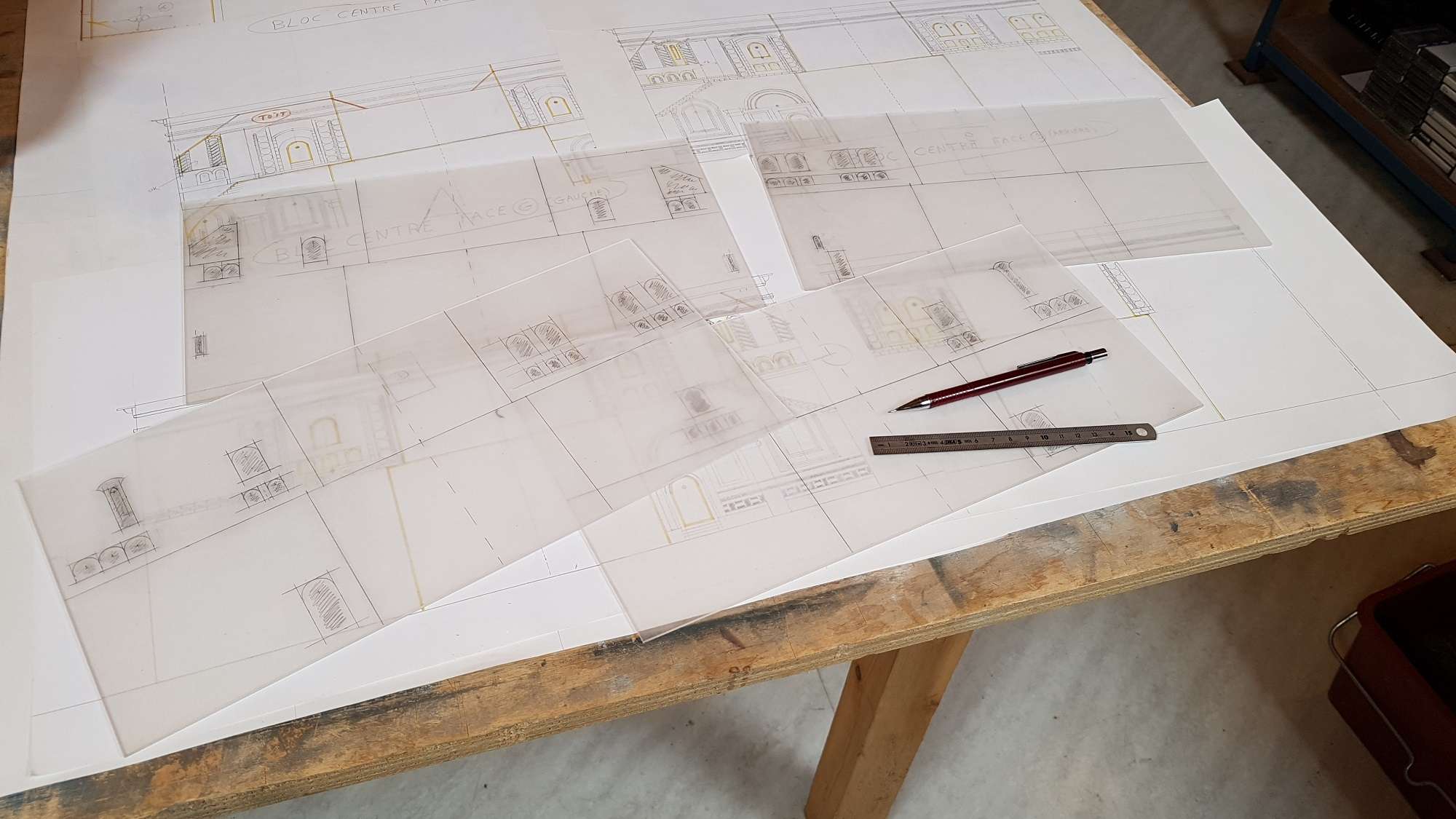

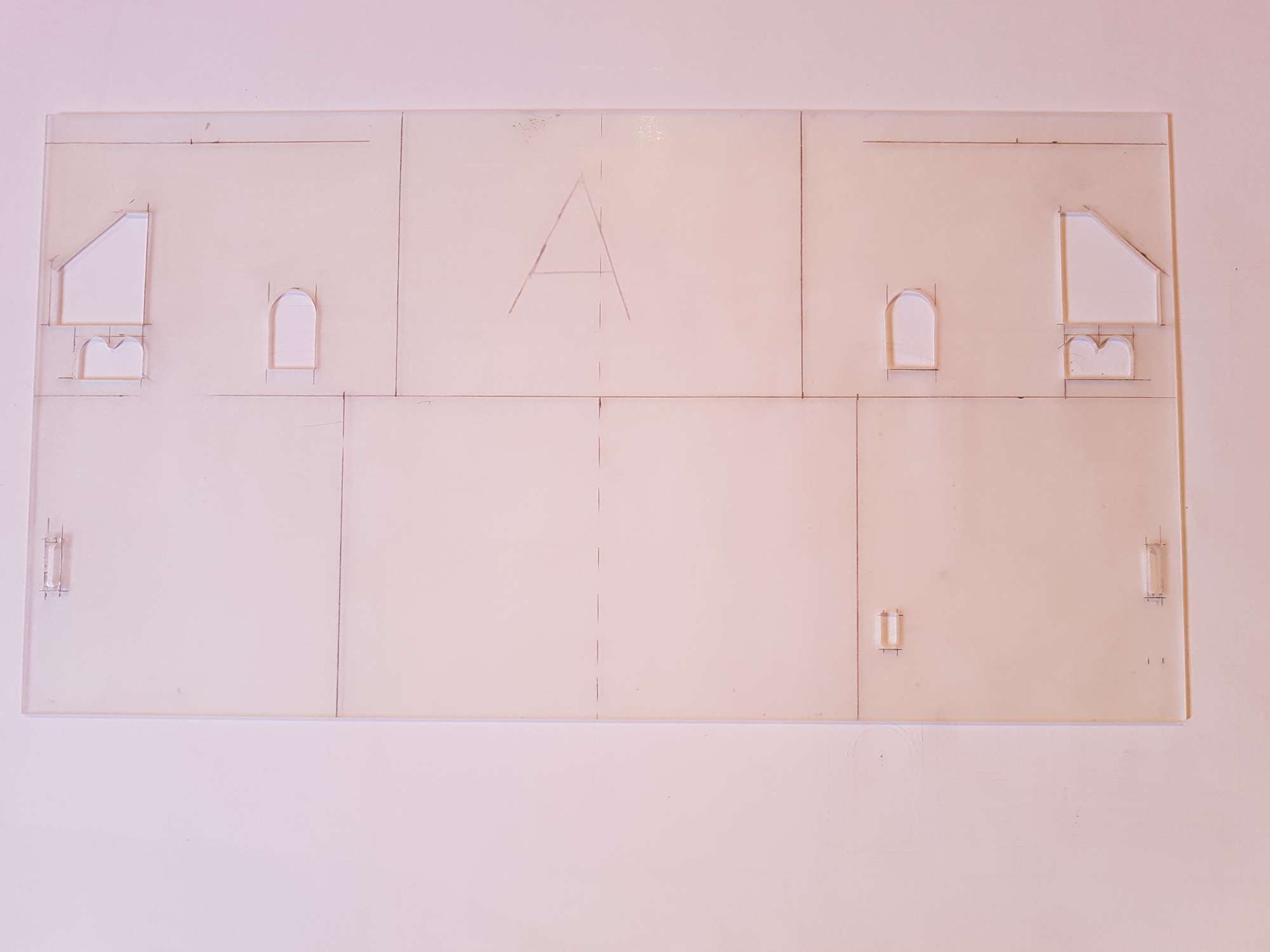

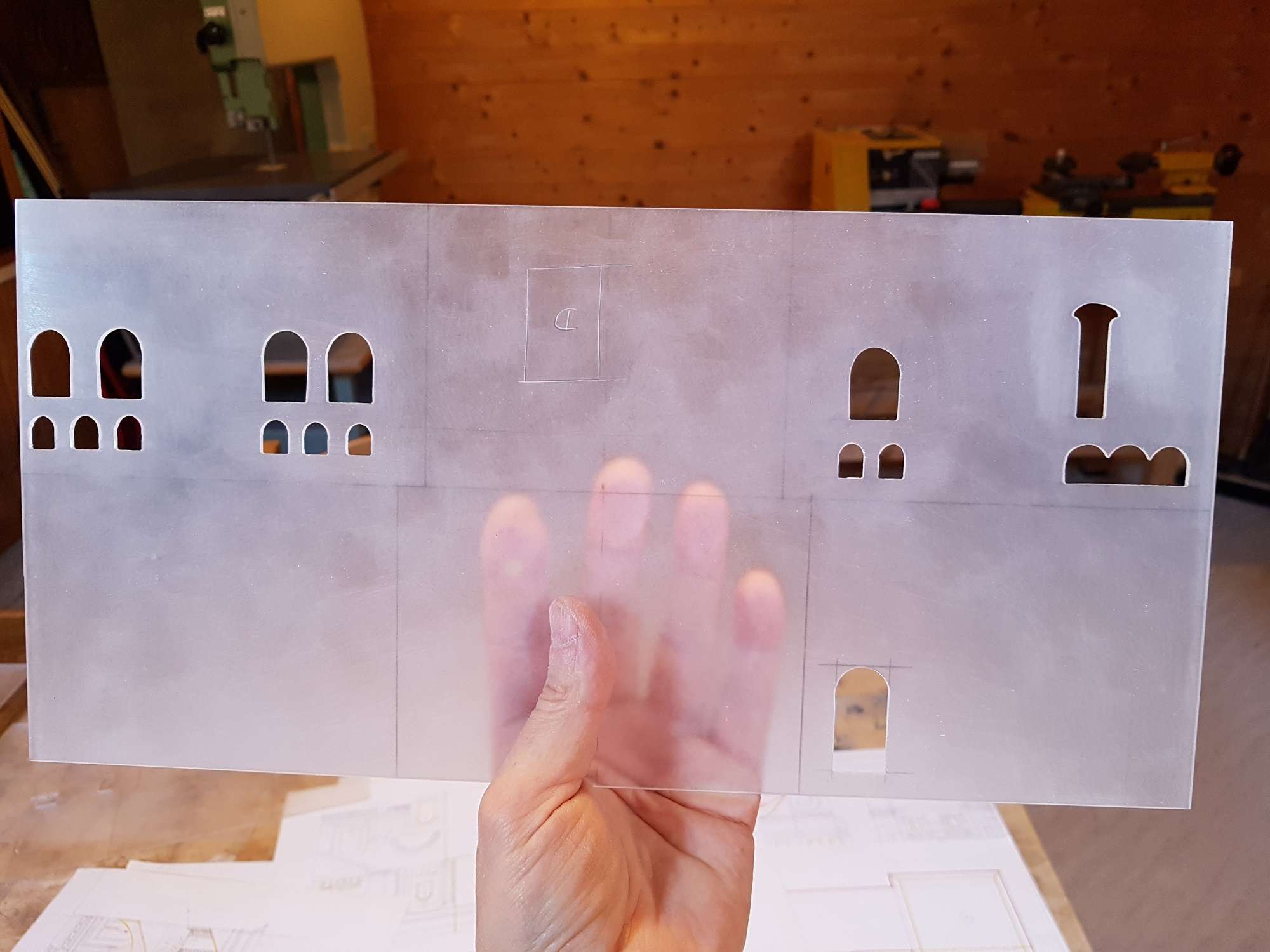

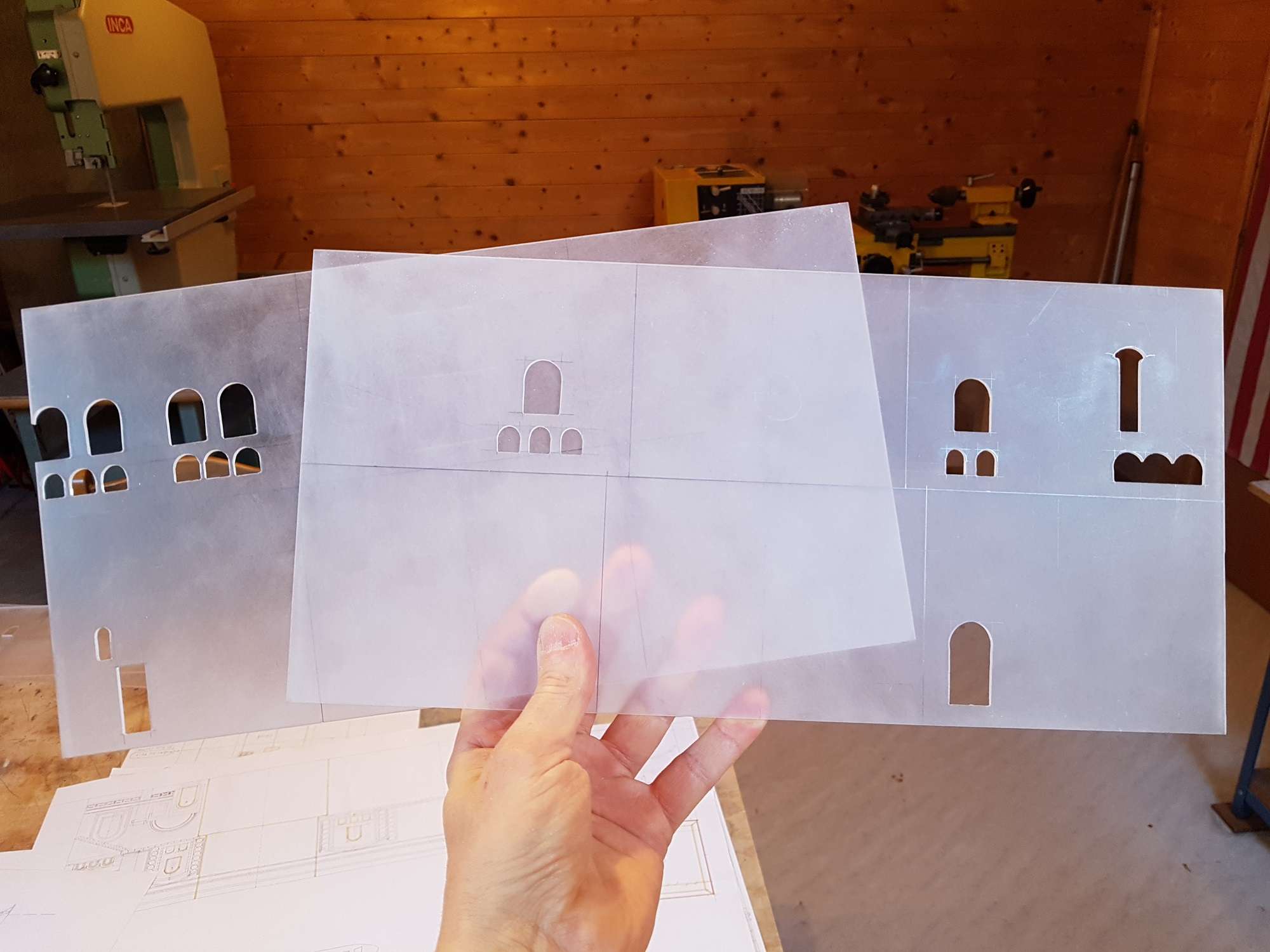

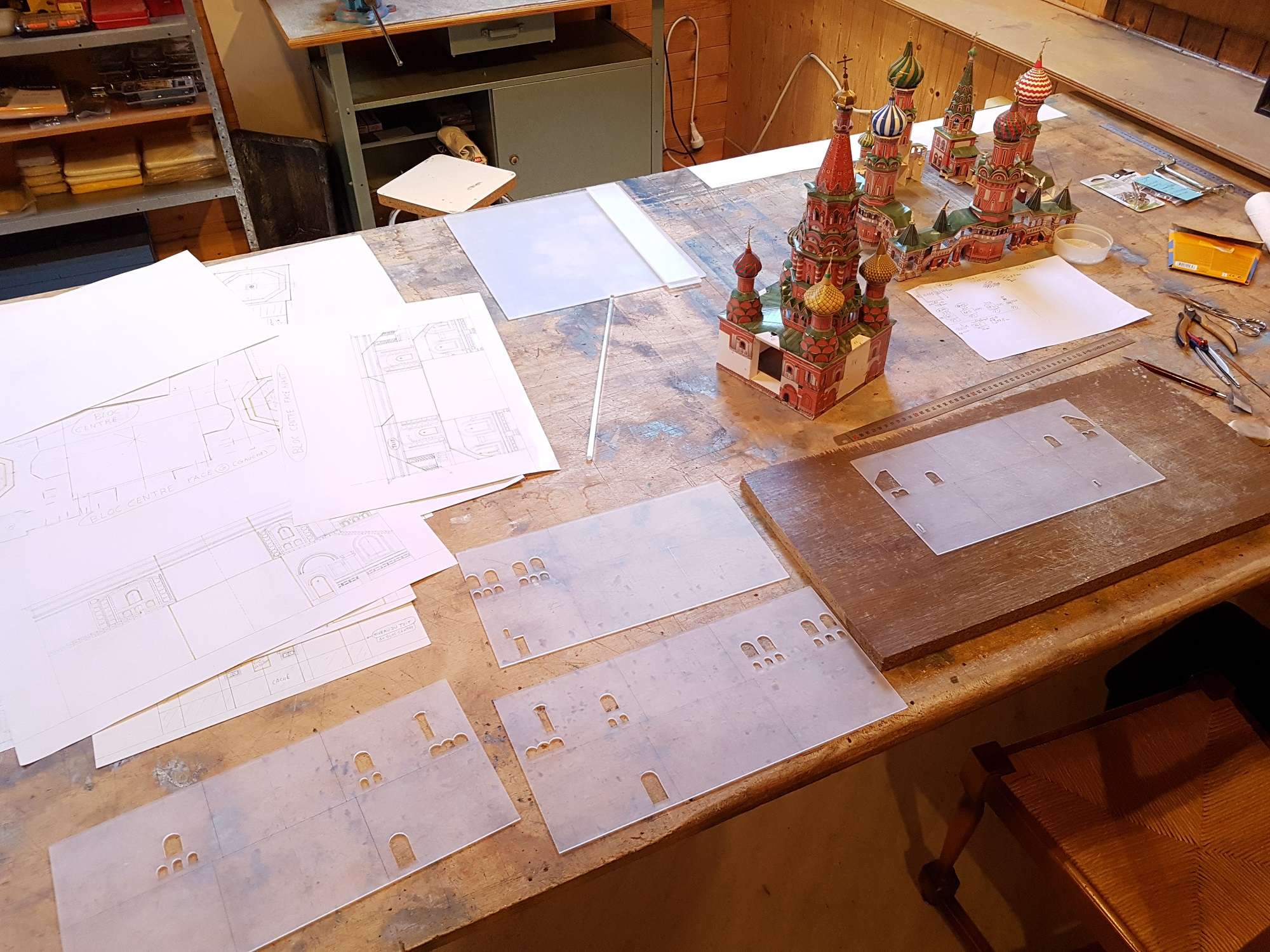

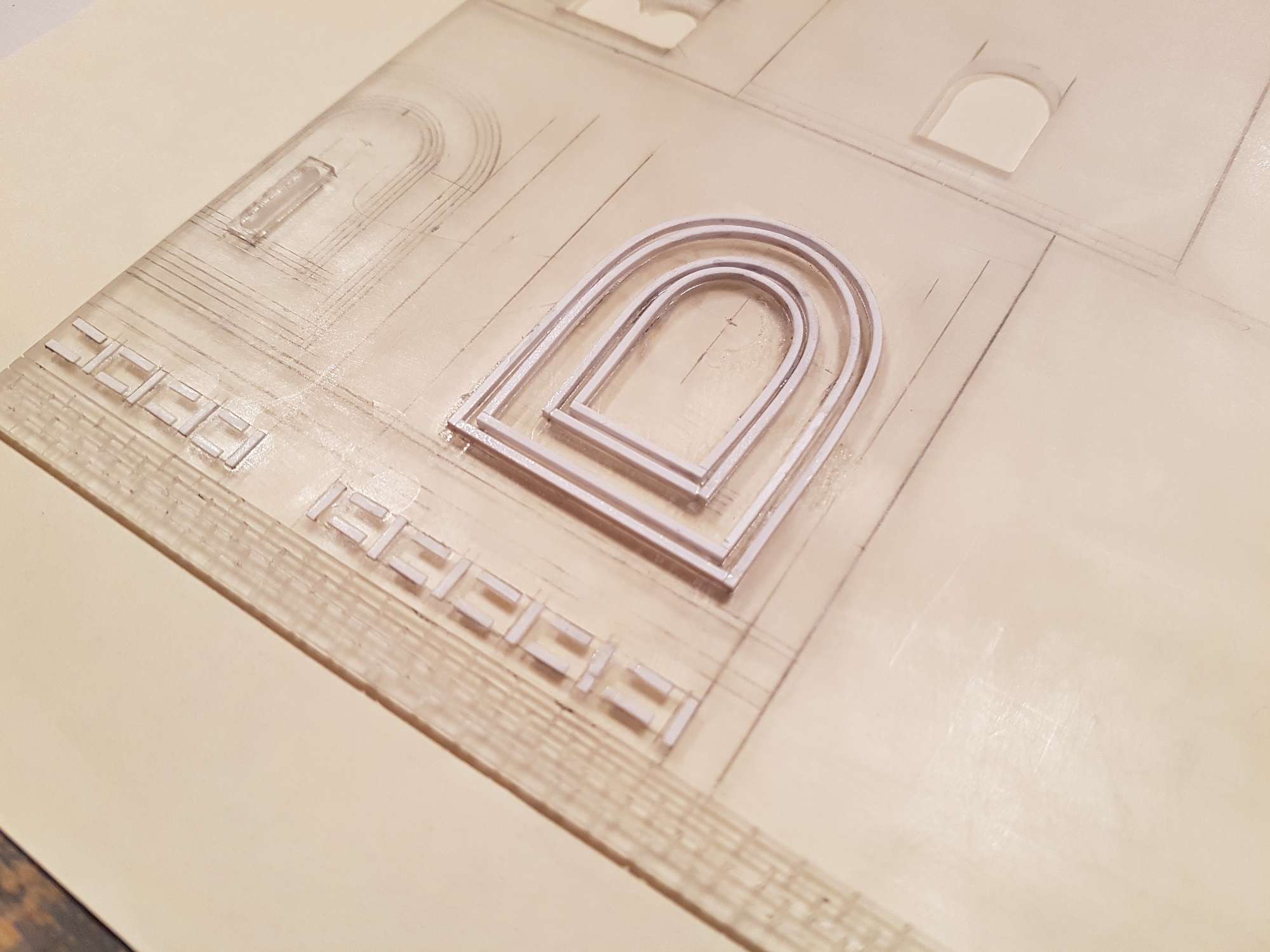

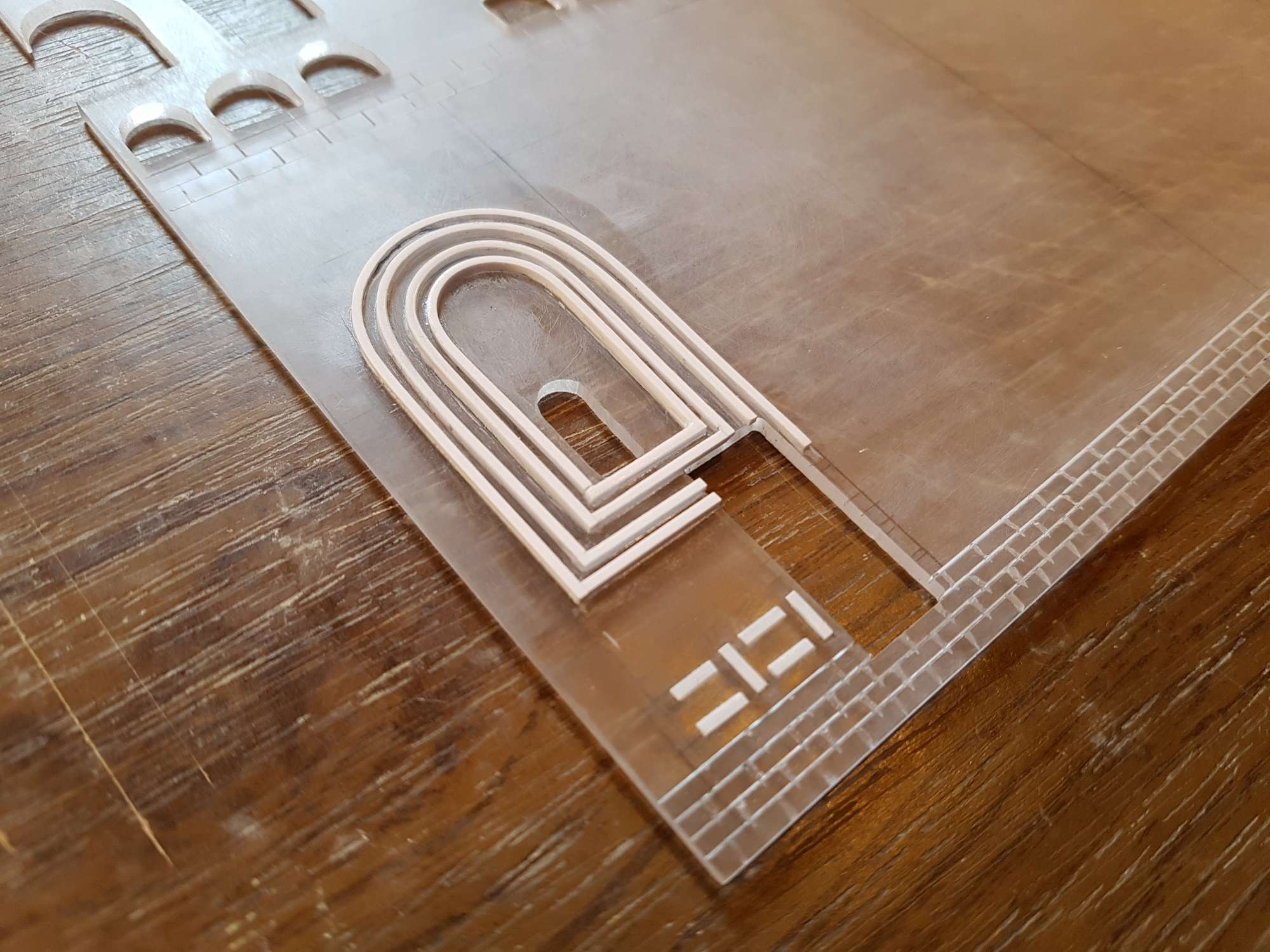

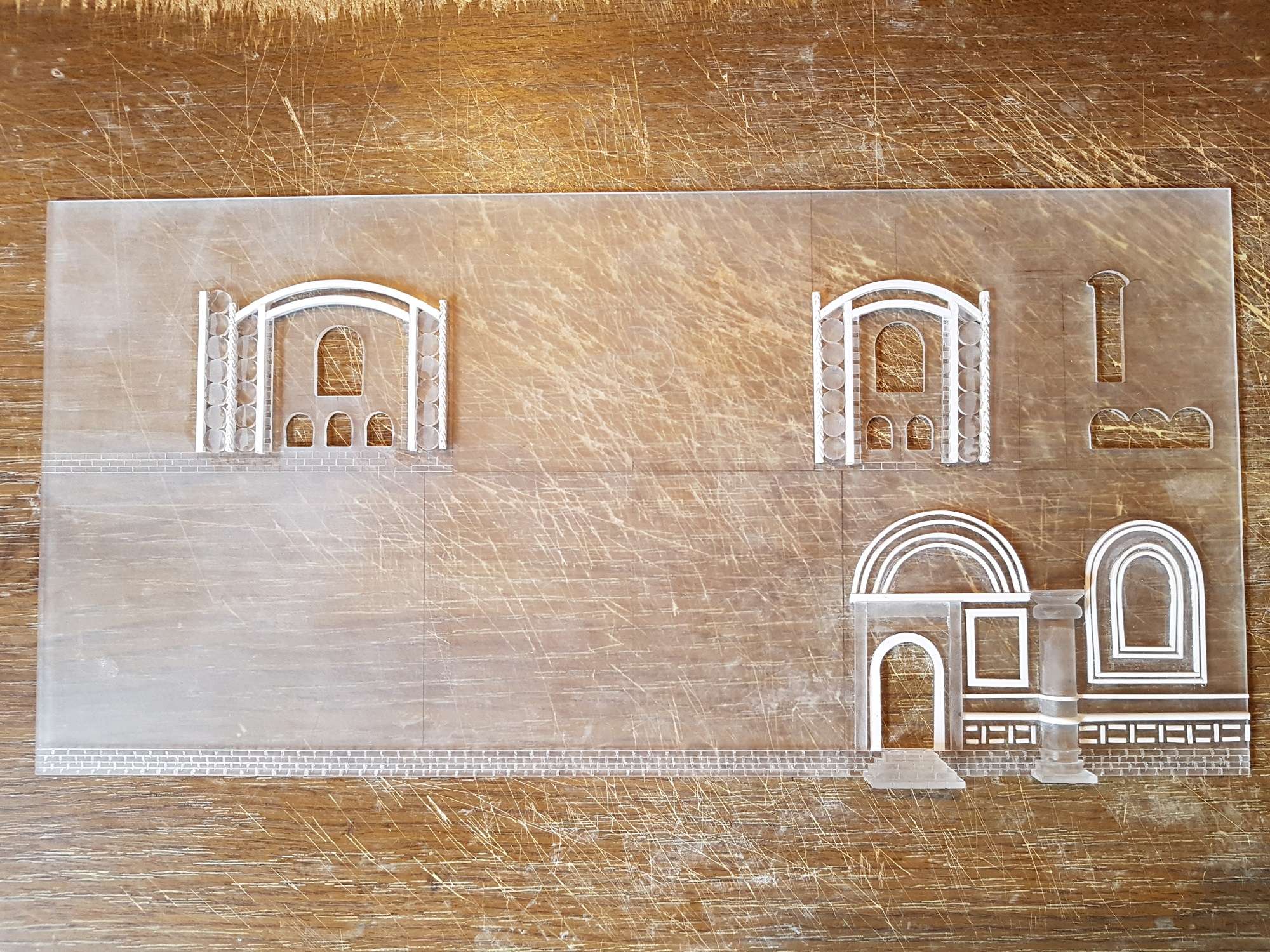

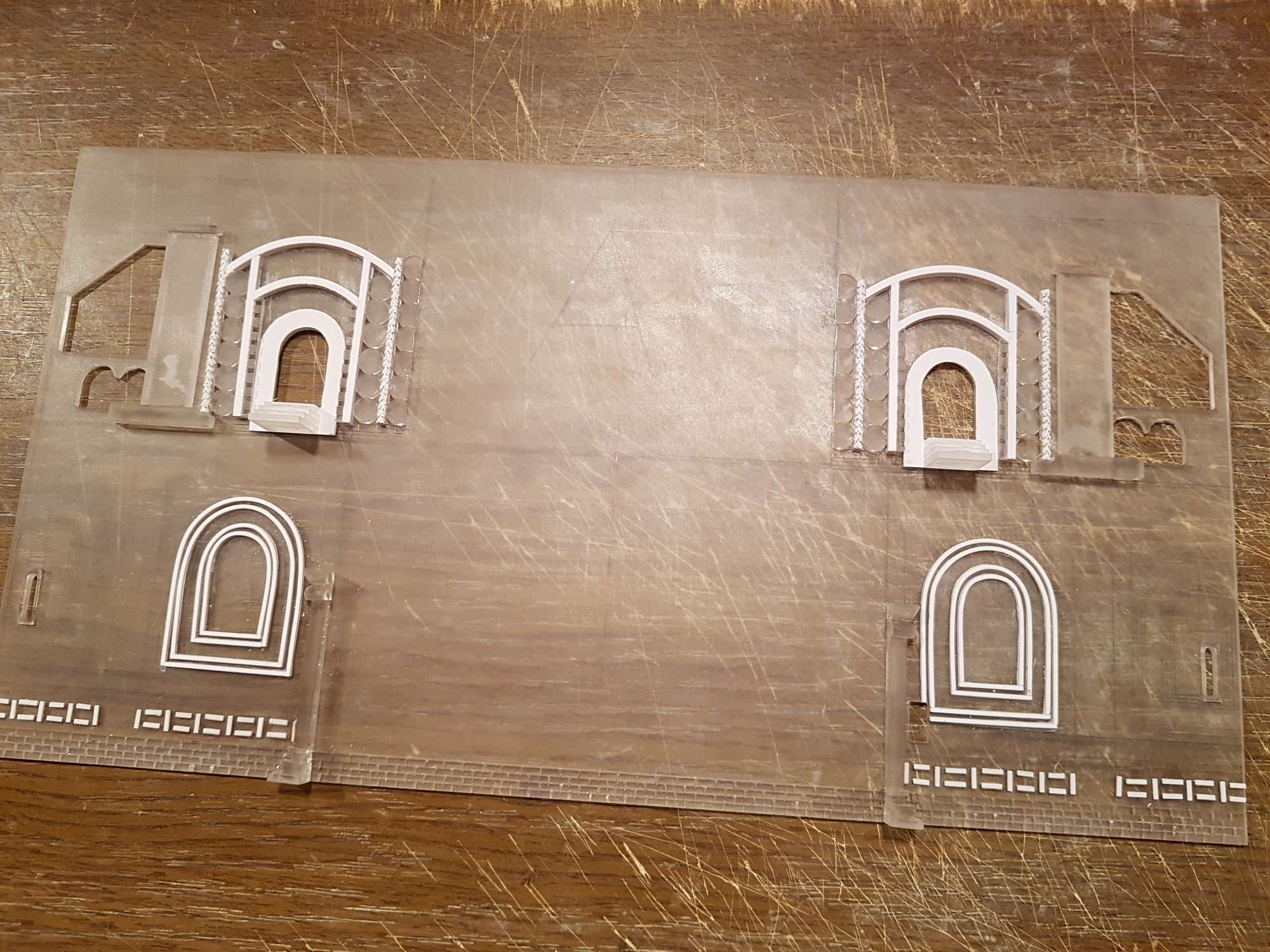

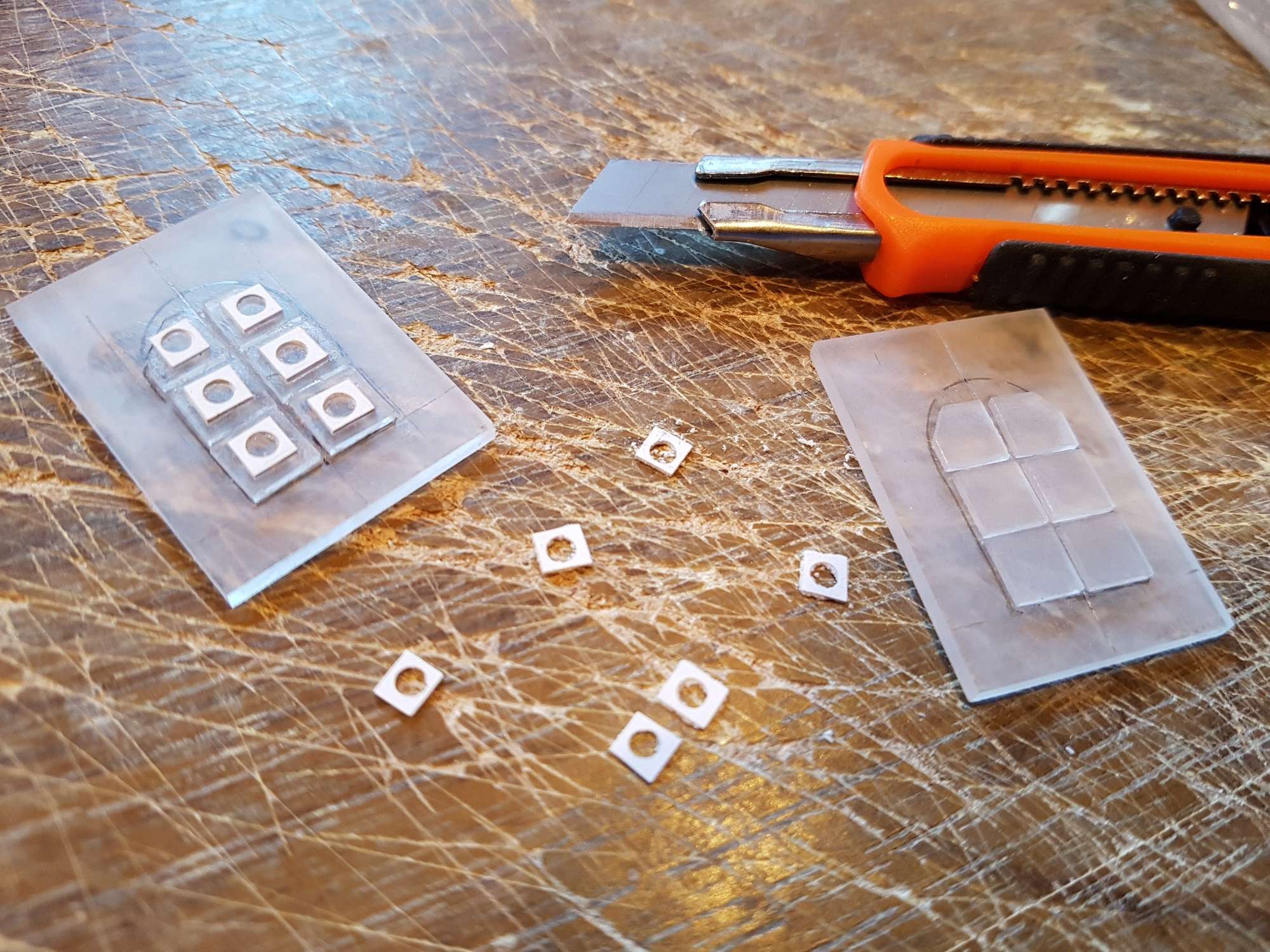

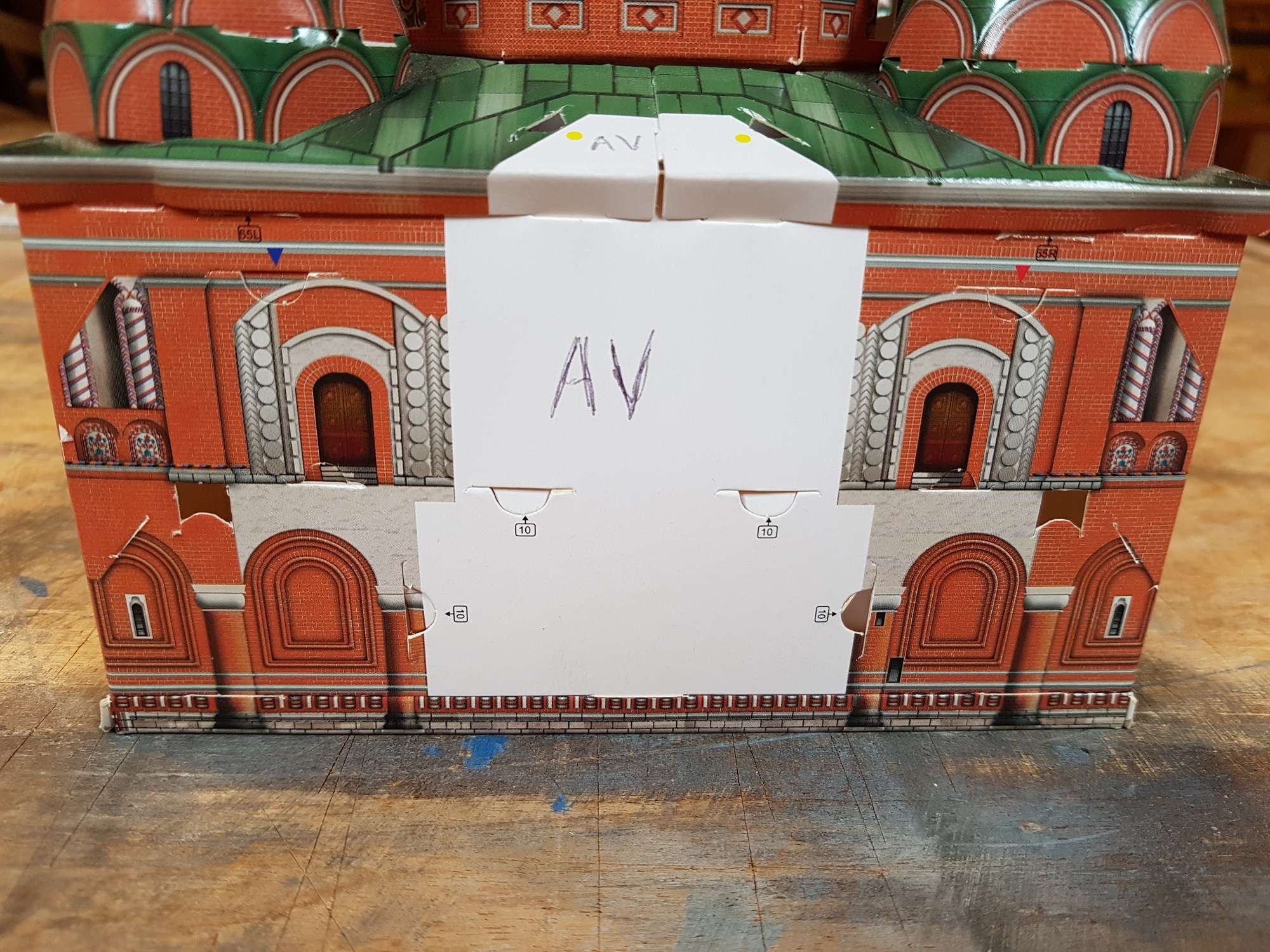

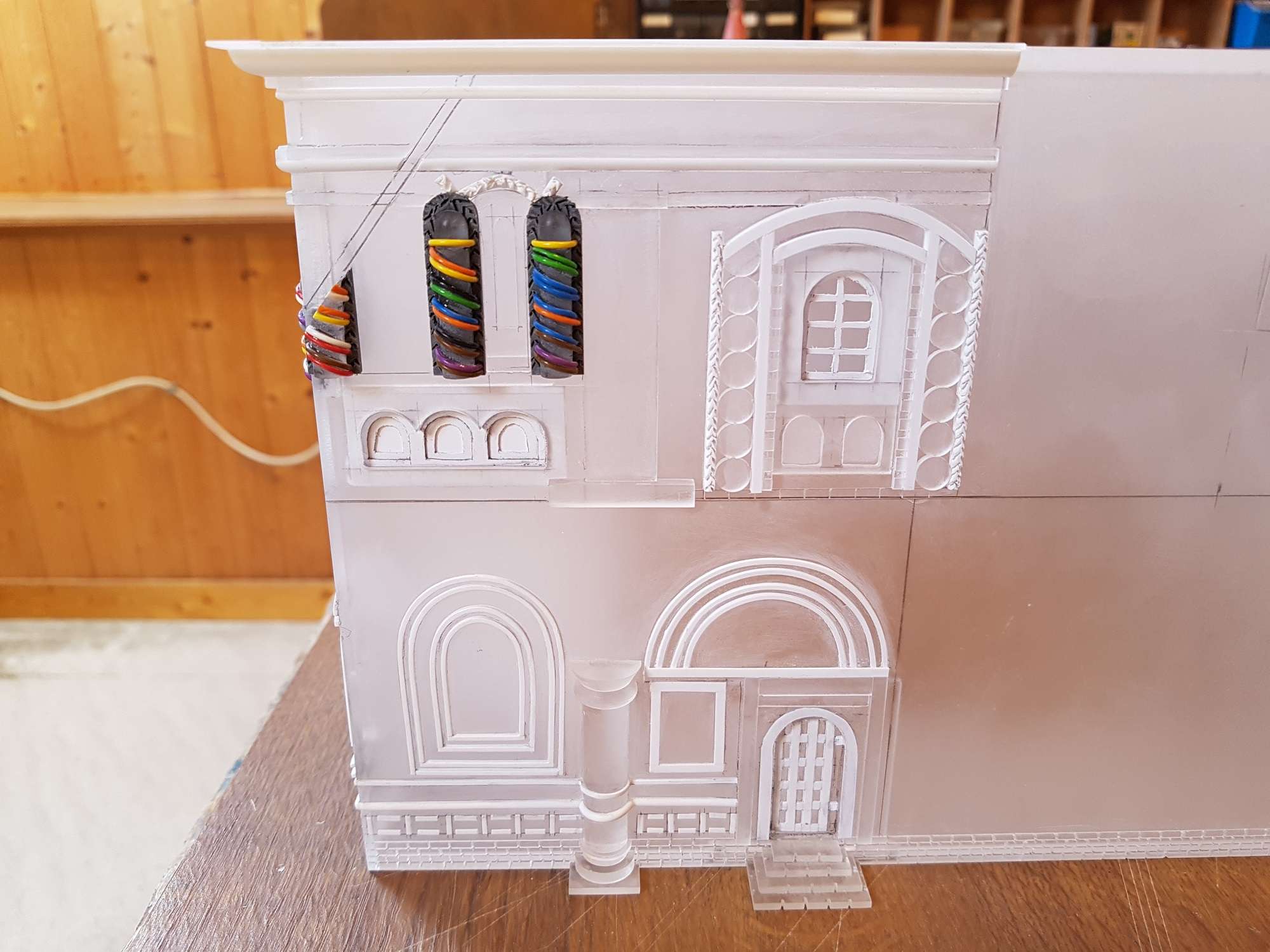

I’m doing the square core of the cathedral, the material I use is plexiglass, a very hard plastic that can be cut, worked and sanded, but only with heavy tolls, a knive isn’t enough! The advantage of this plastic is durability, it doesn’t suffer damage with time and weather, this is what I used for my Egyptian temple 30 years ago, and today it’s still as fresh and new as it was some decades ago. When I spend thousands hours work on a model I like to see it lasting forever!

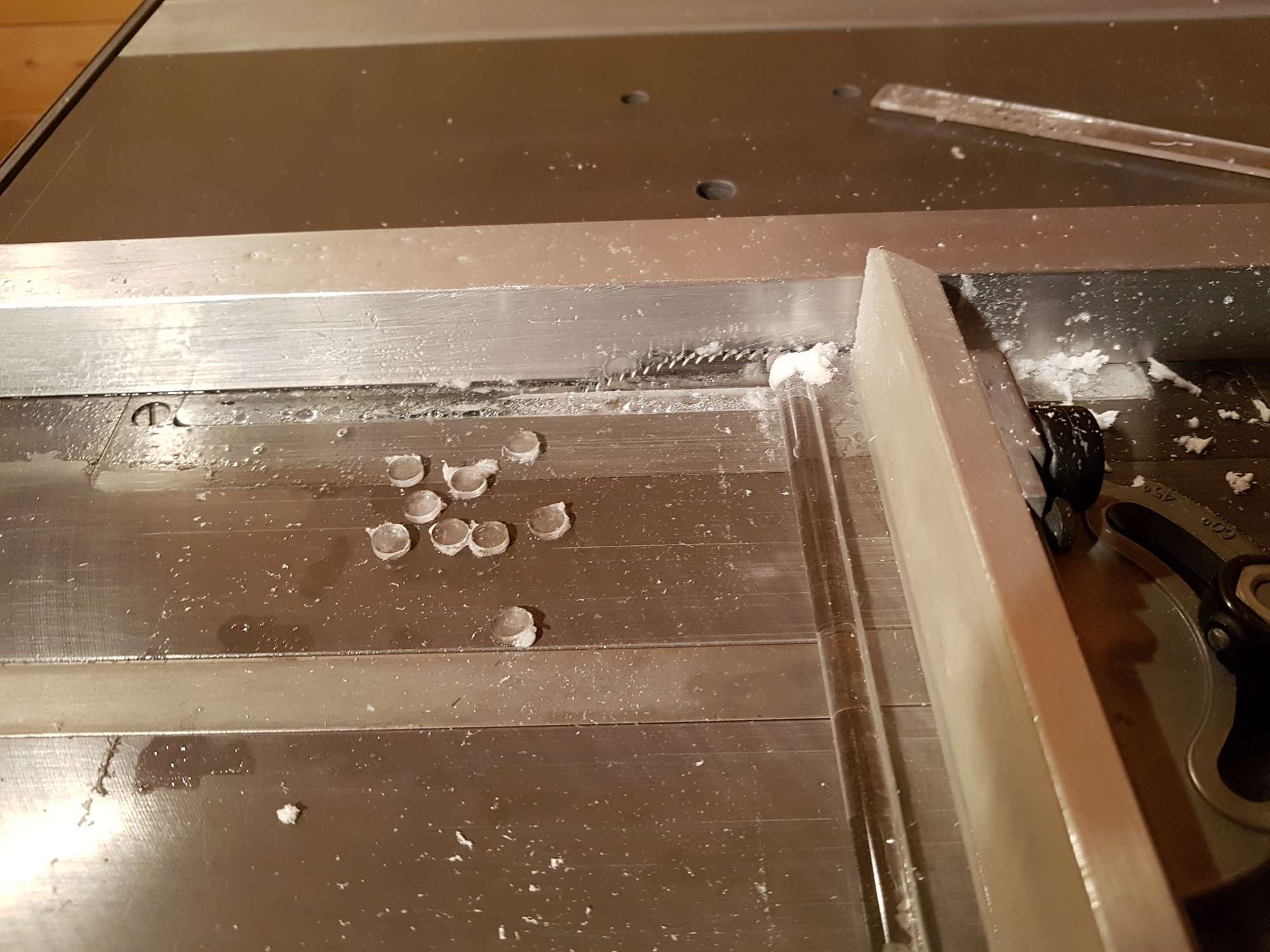

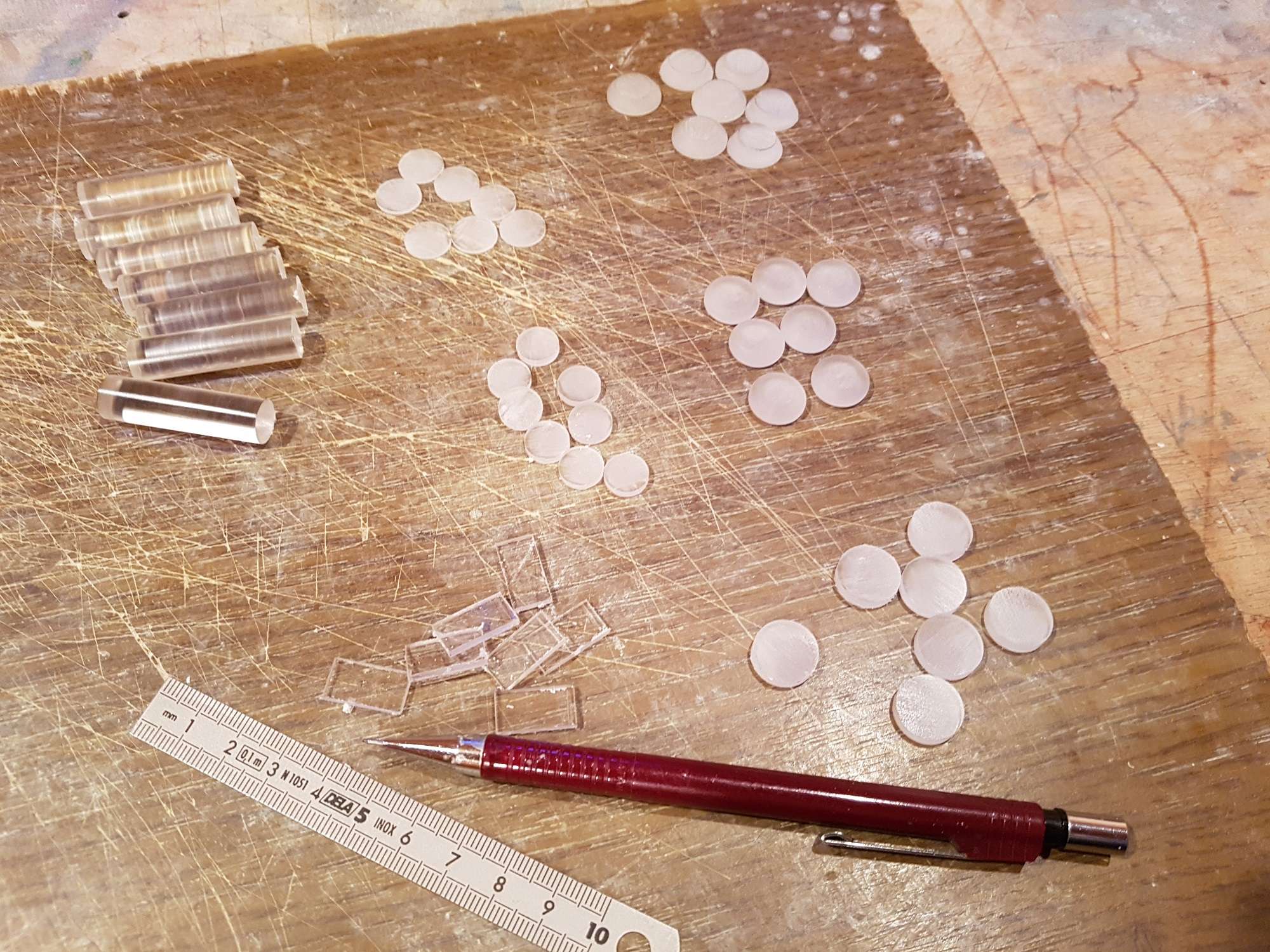

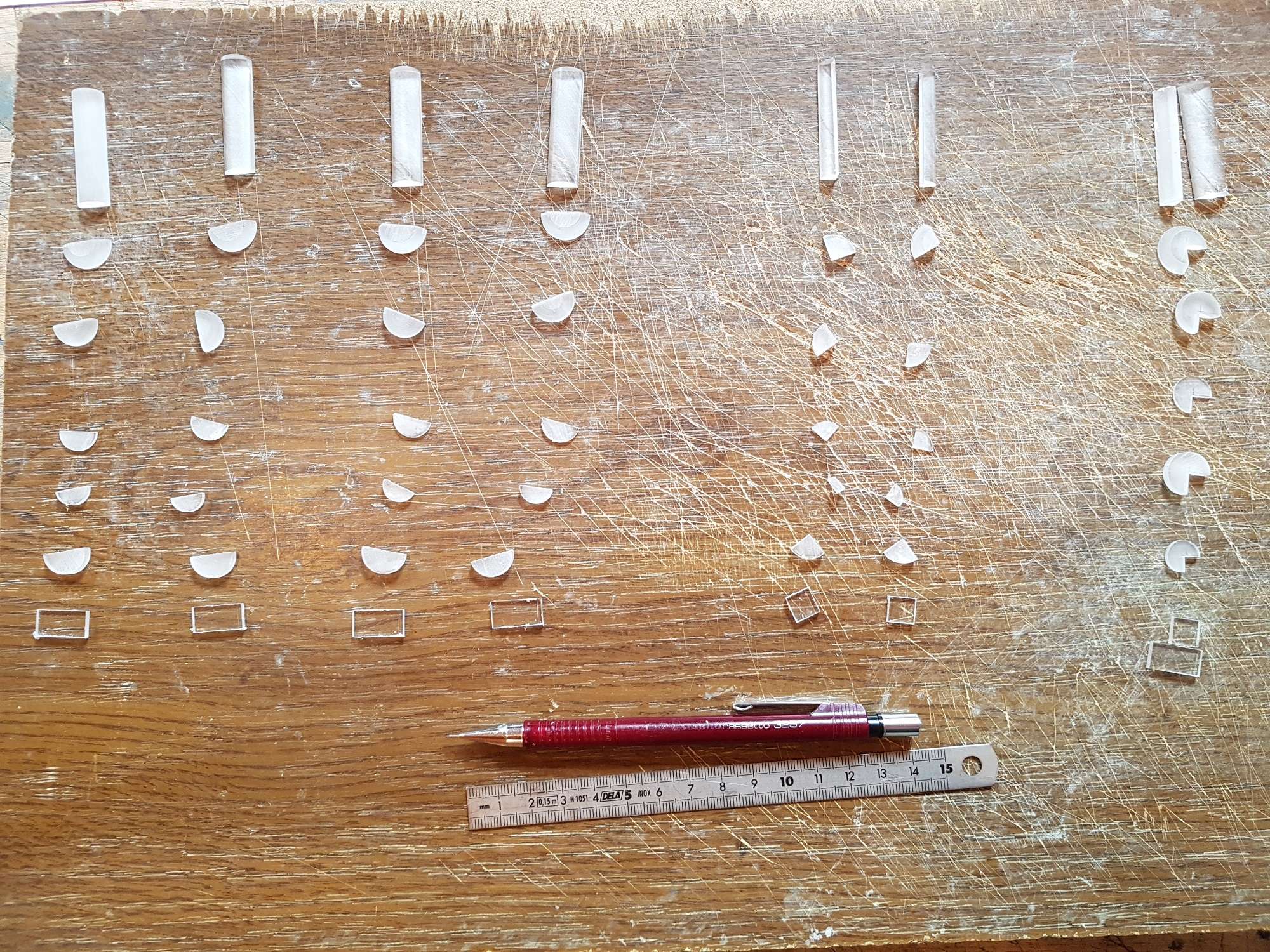

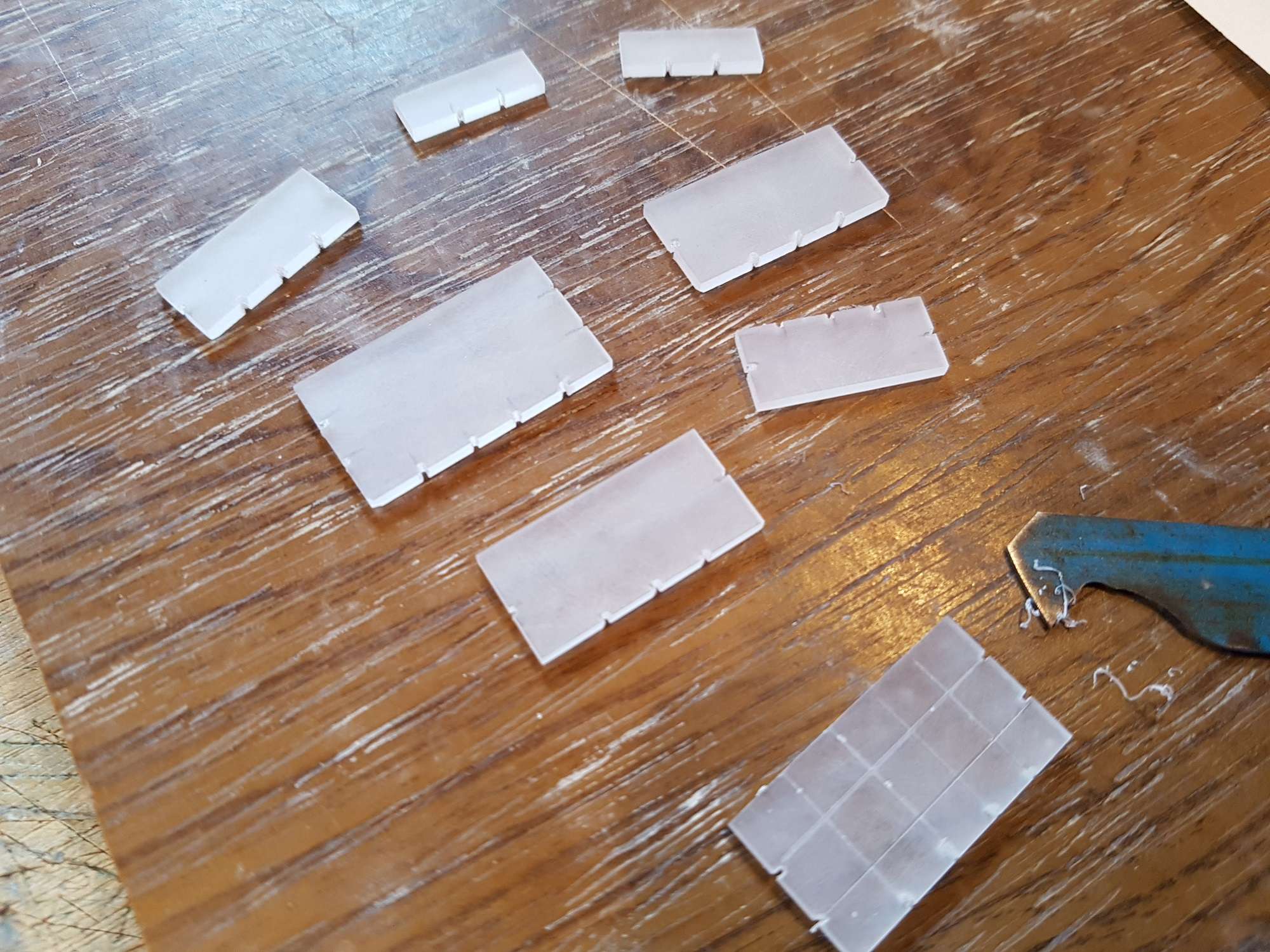

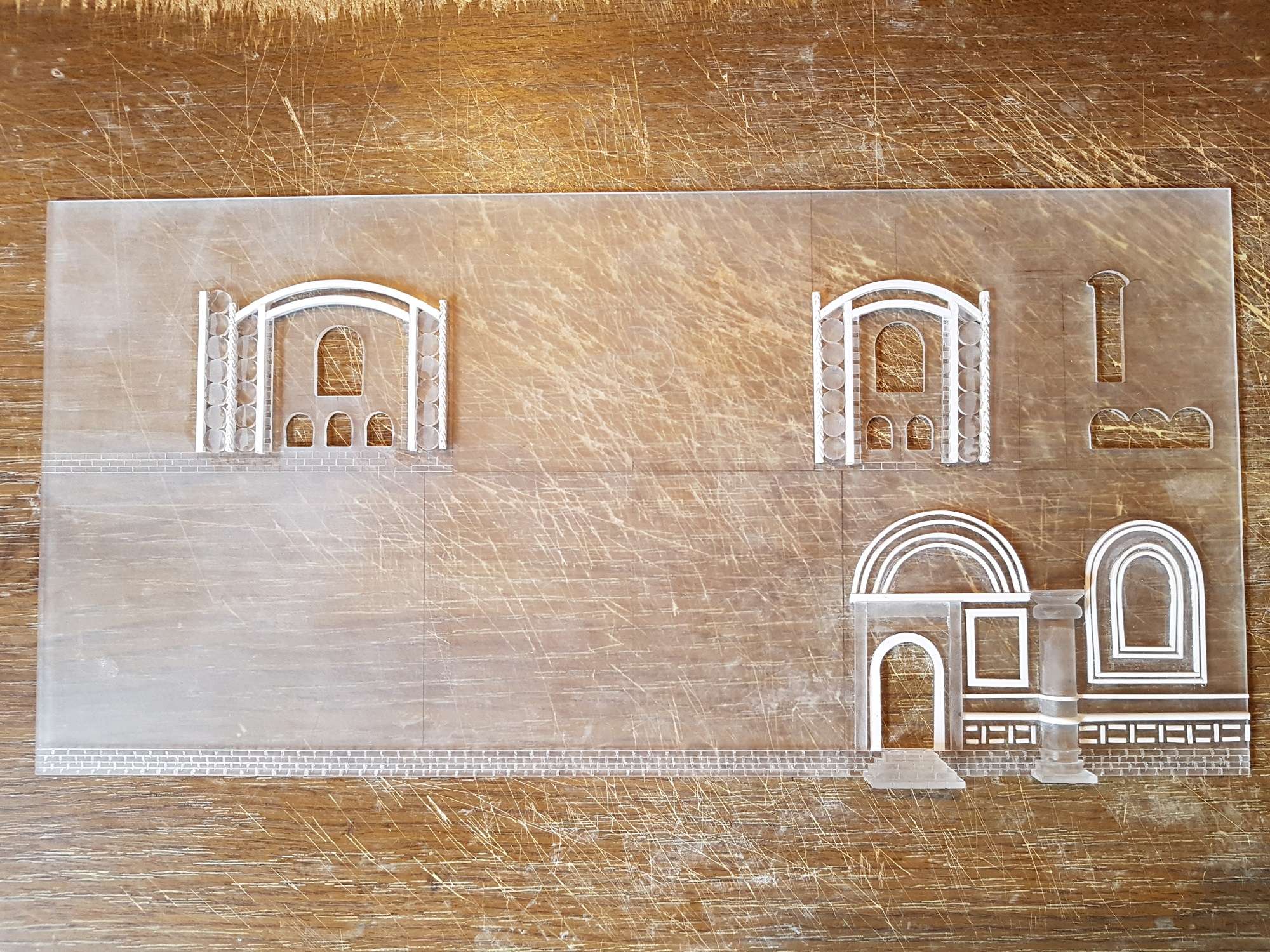

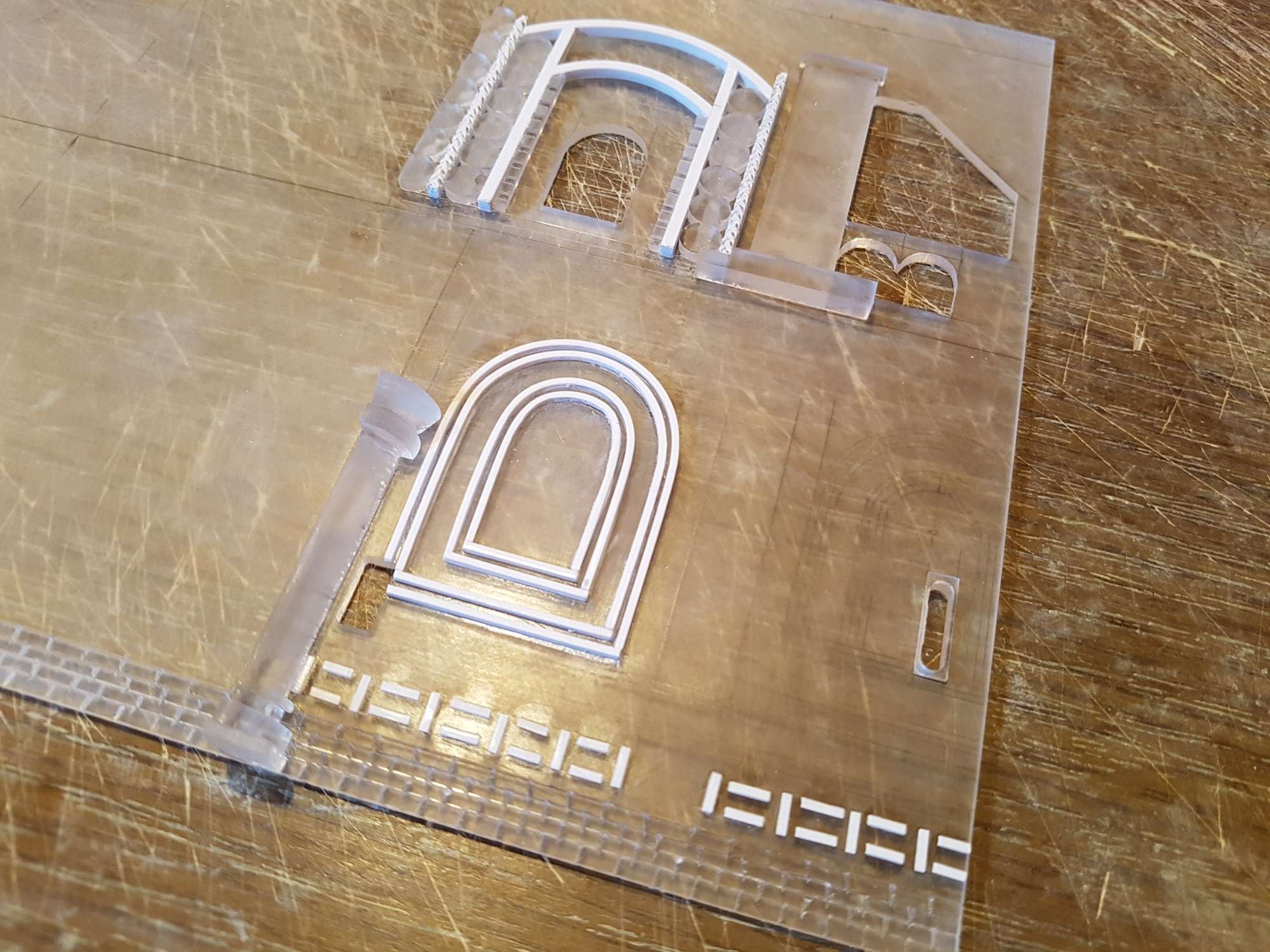

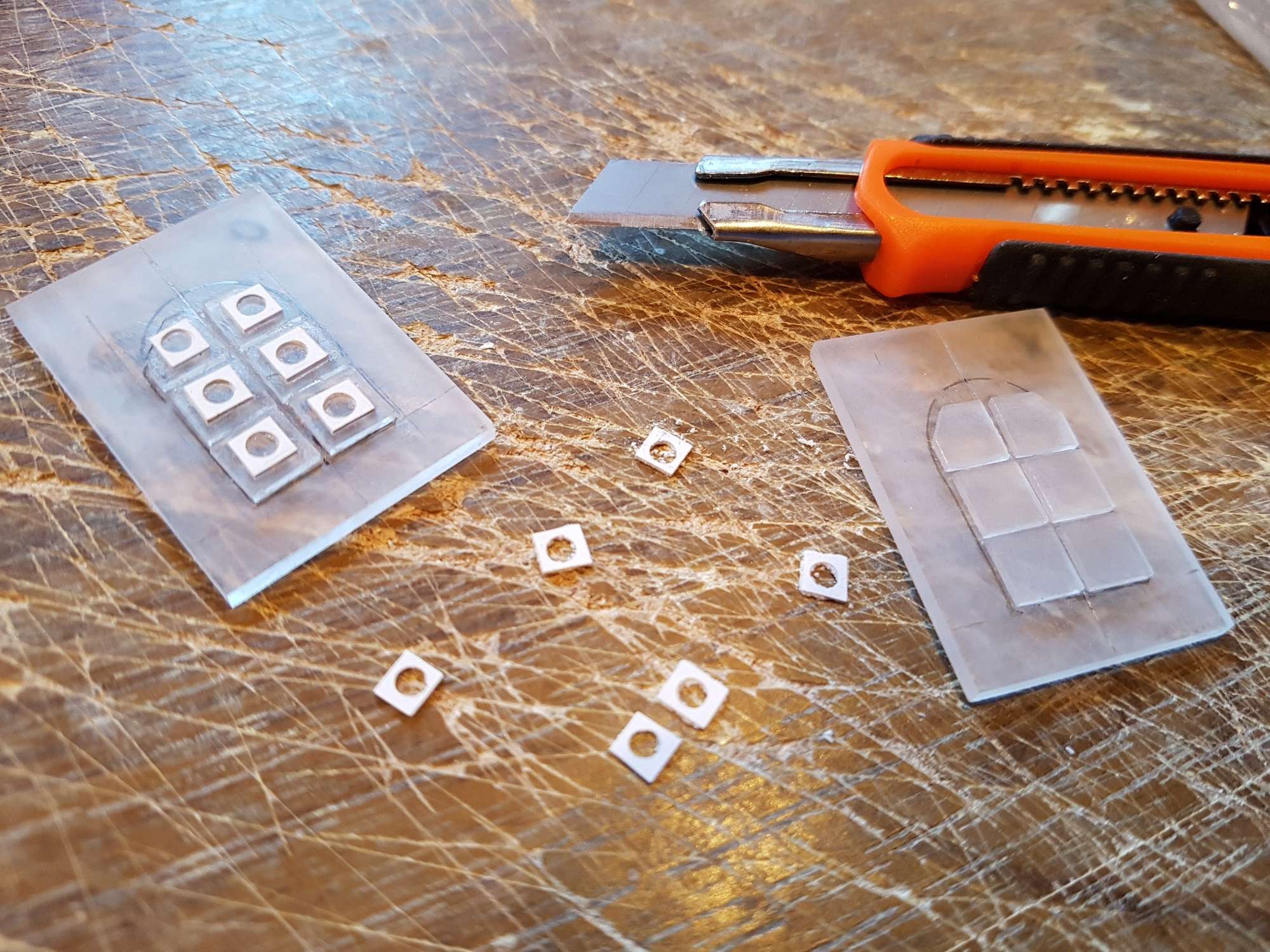

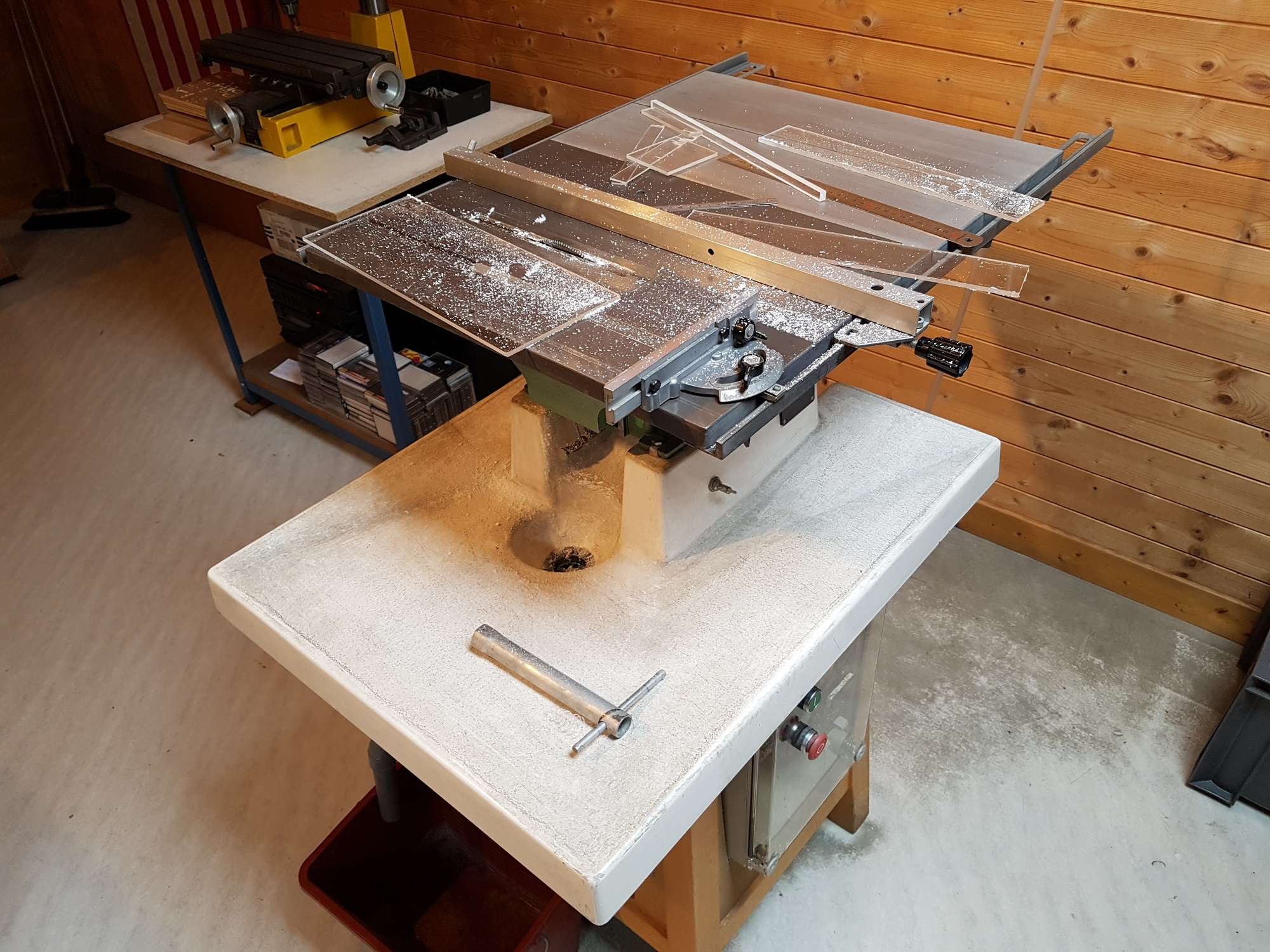

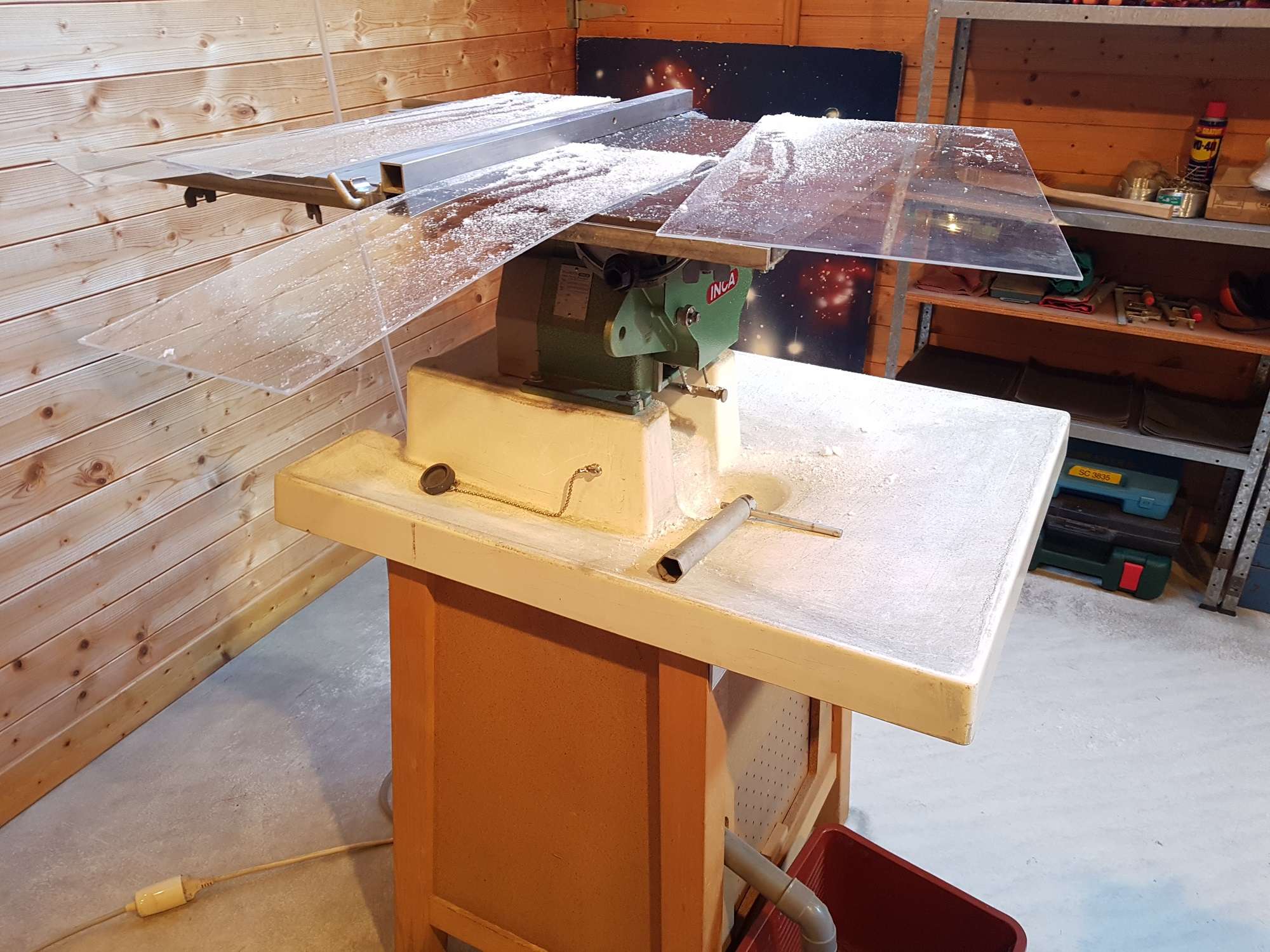

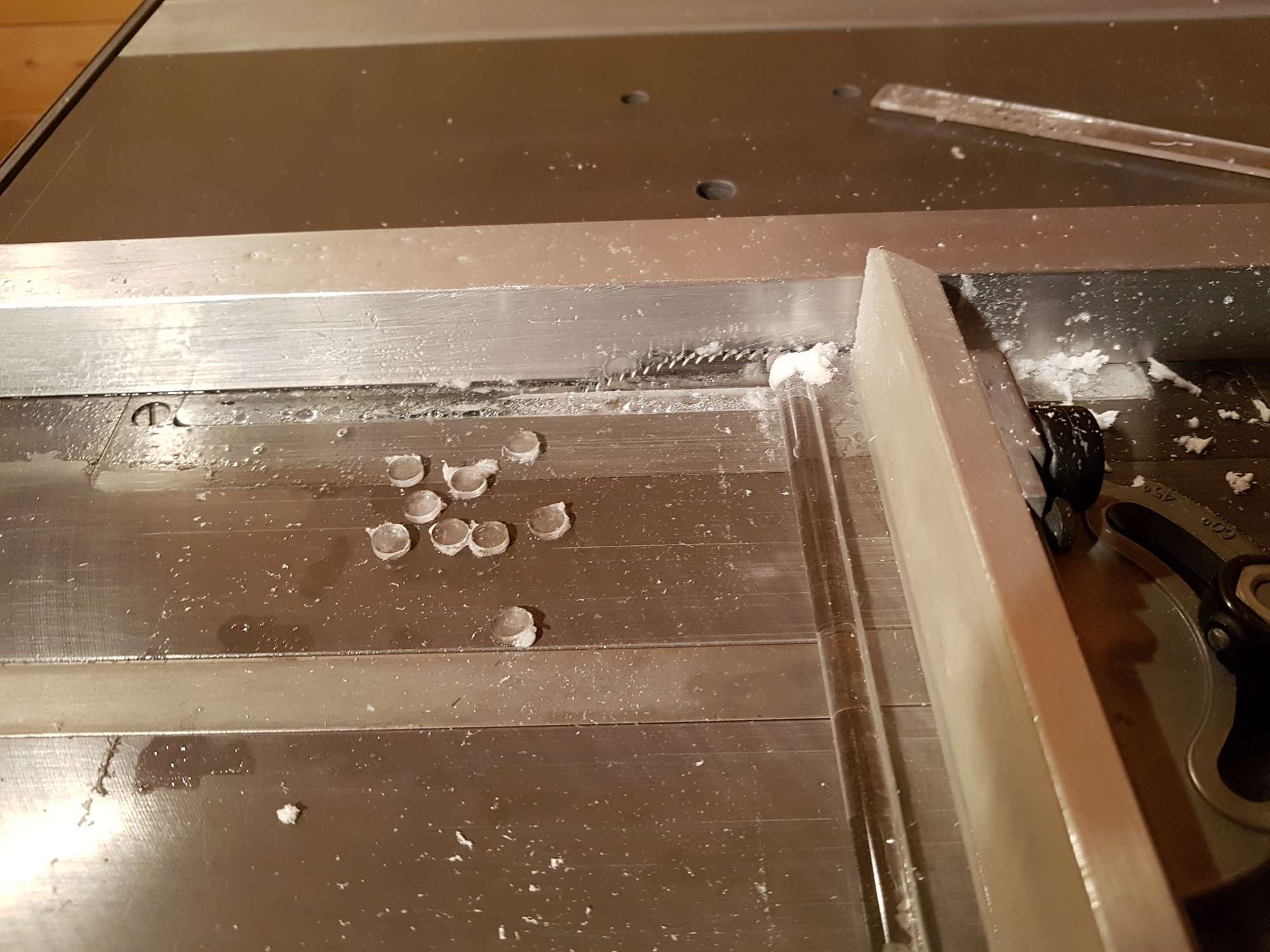

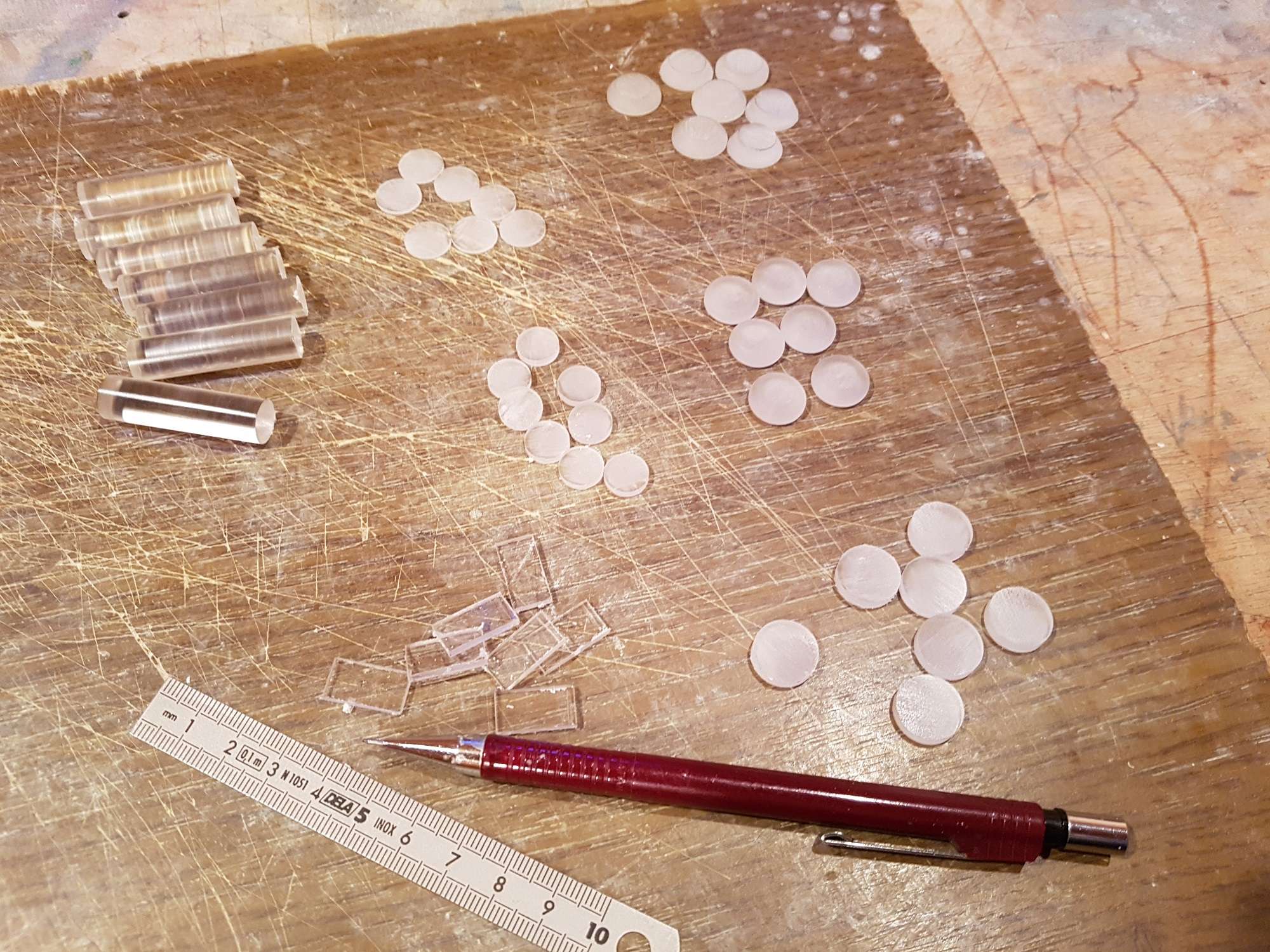

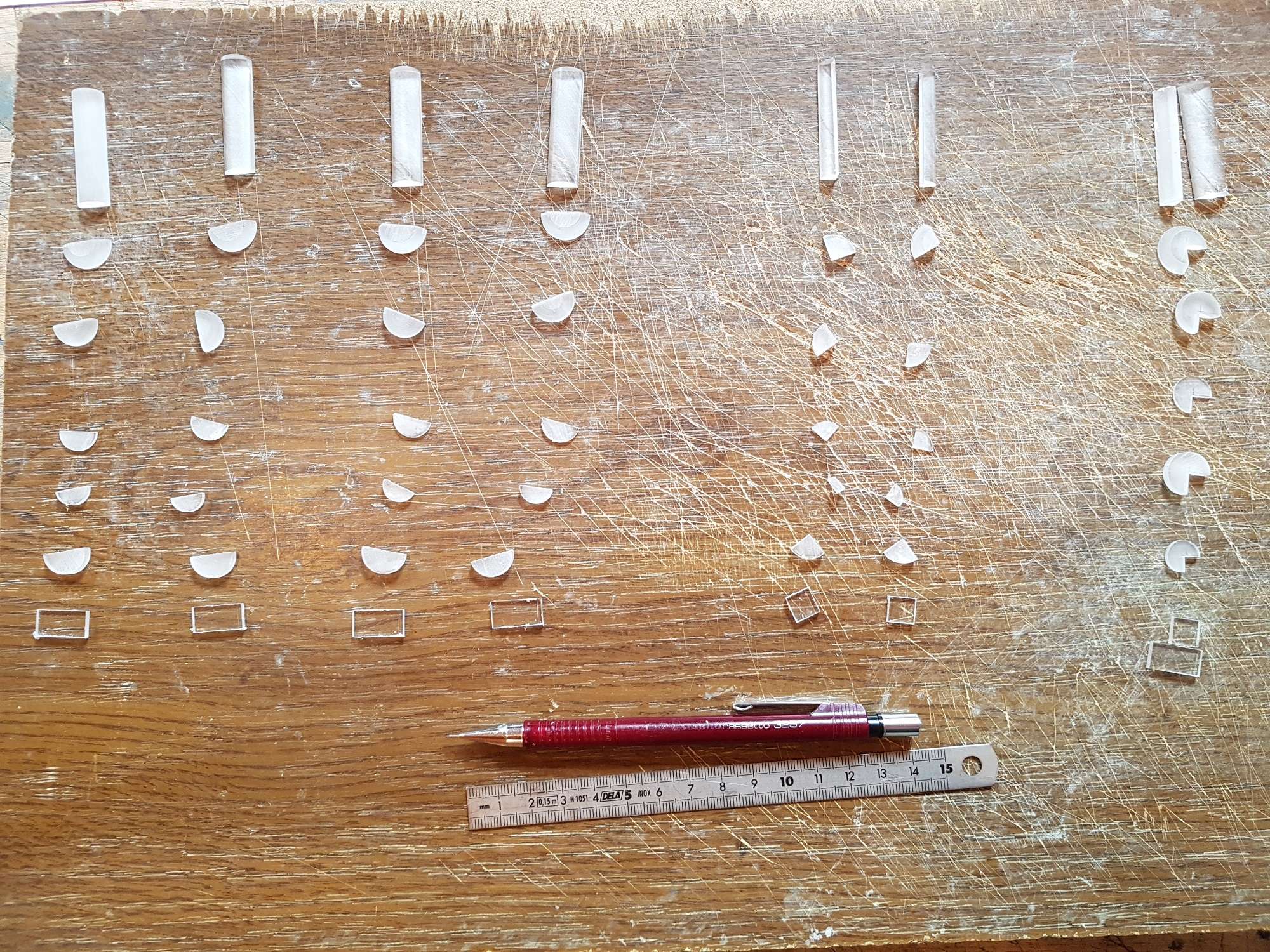

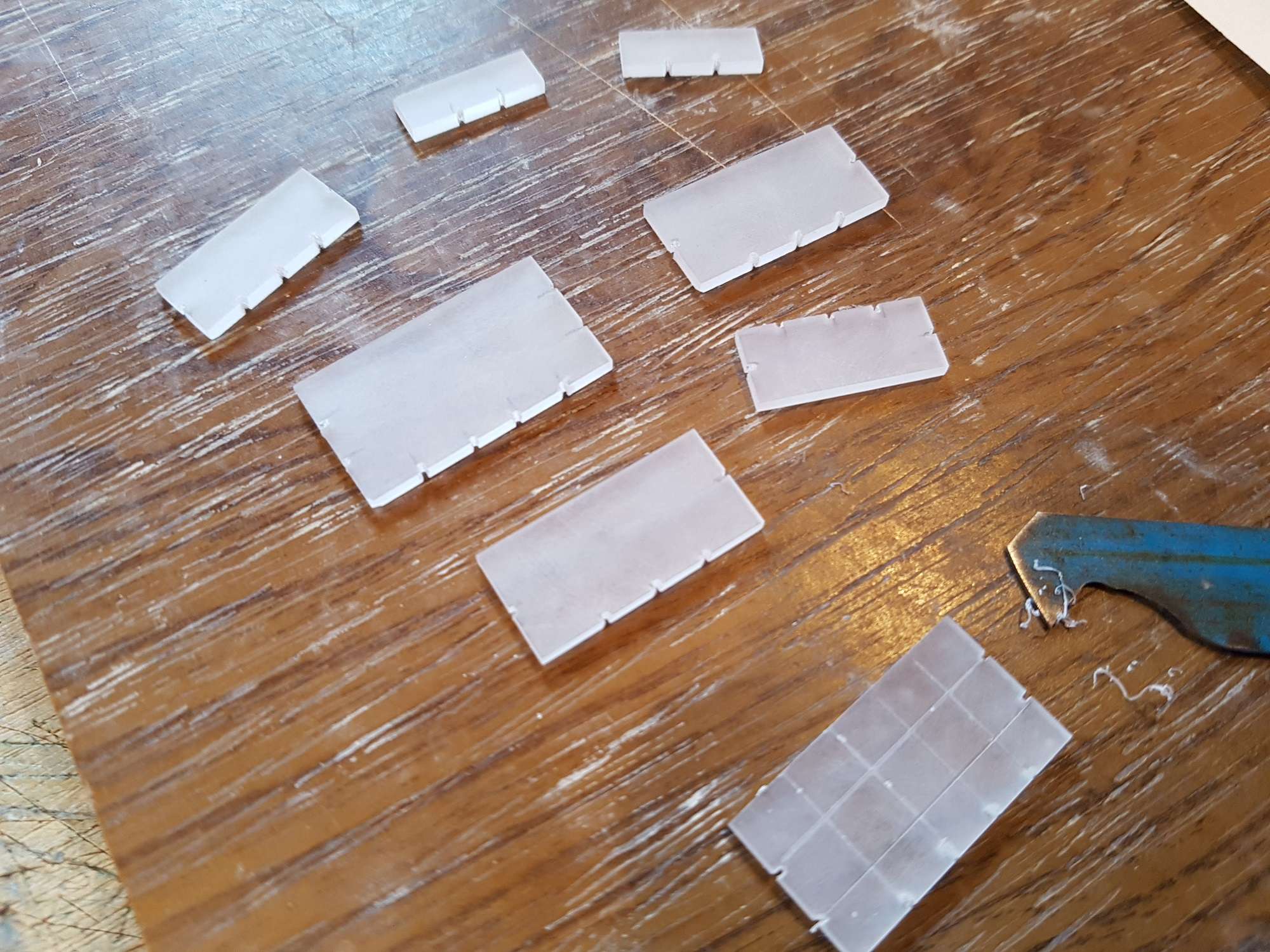

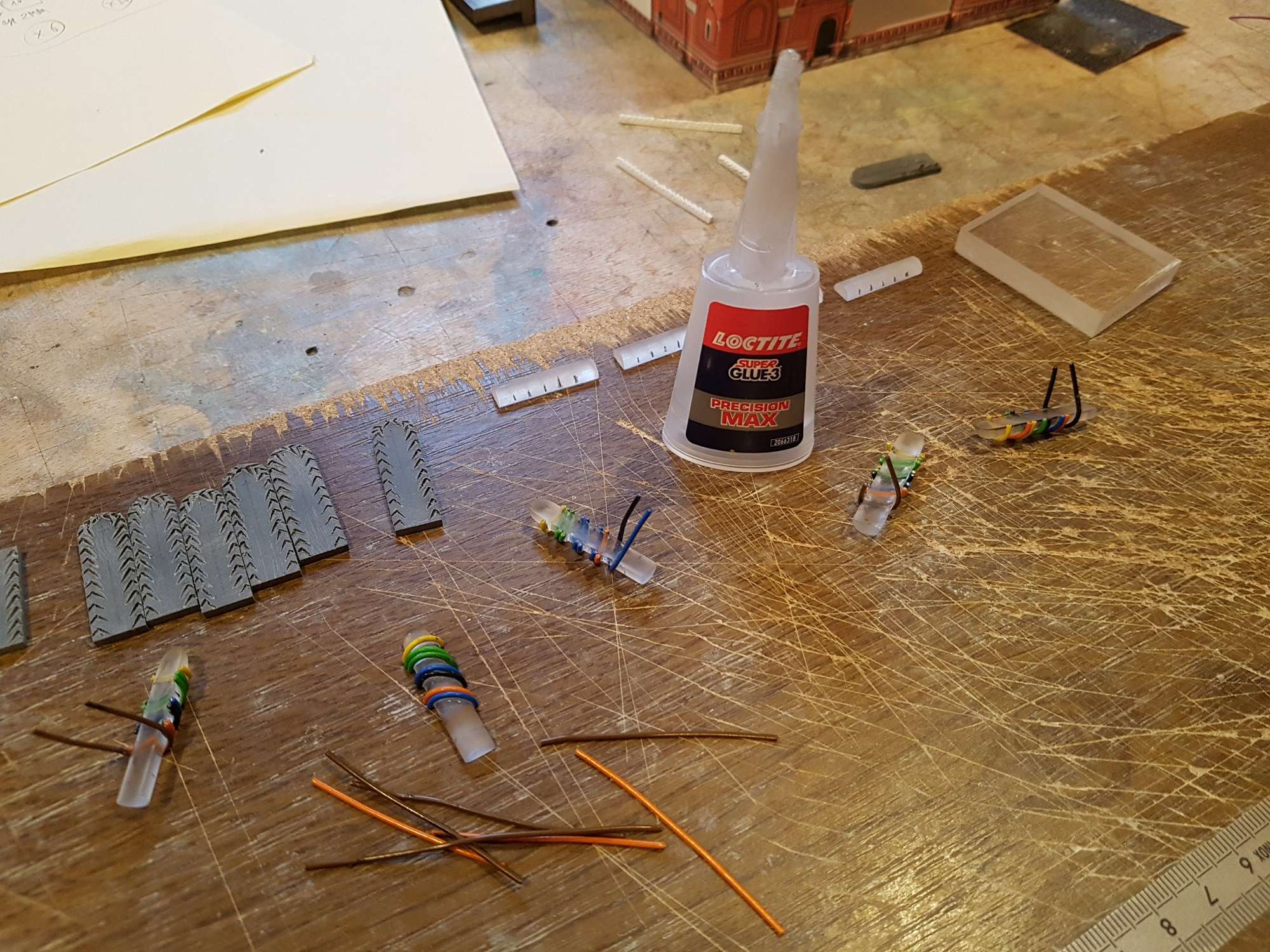

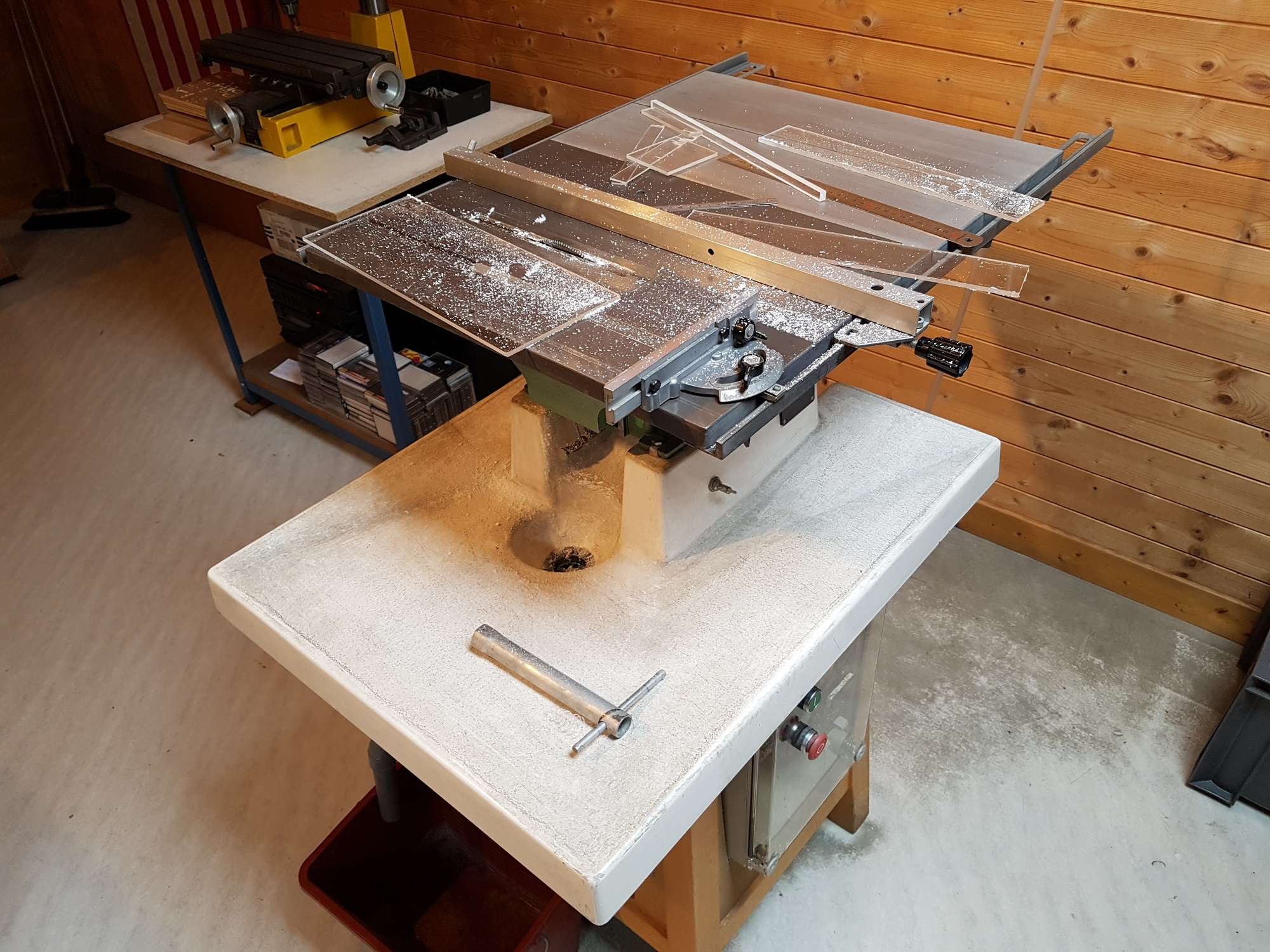

The blade of the circular saw is automatically refreshed with water while working so the plexiglass doesn’t heat, it’s specific for this material. Big plates and small parts are prepared, cut and sanded by hand.

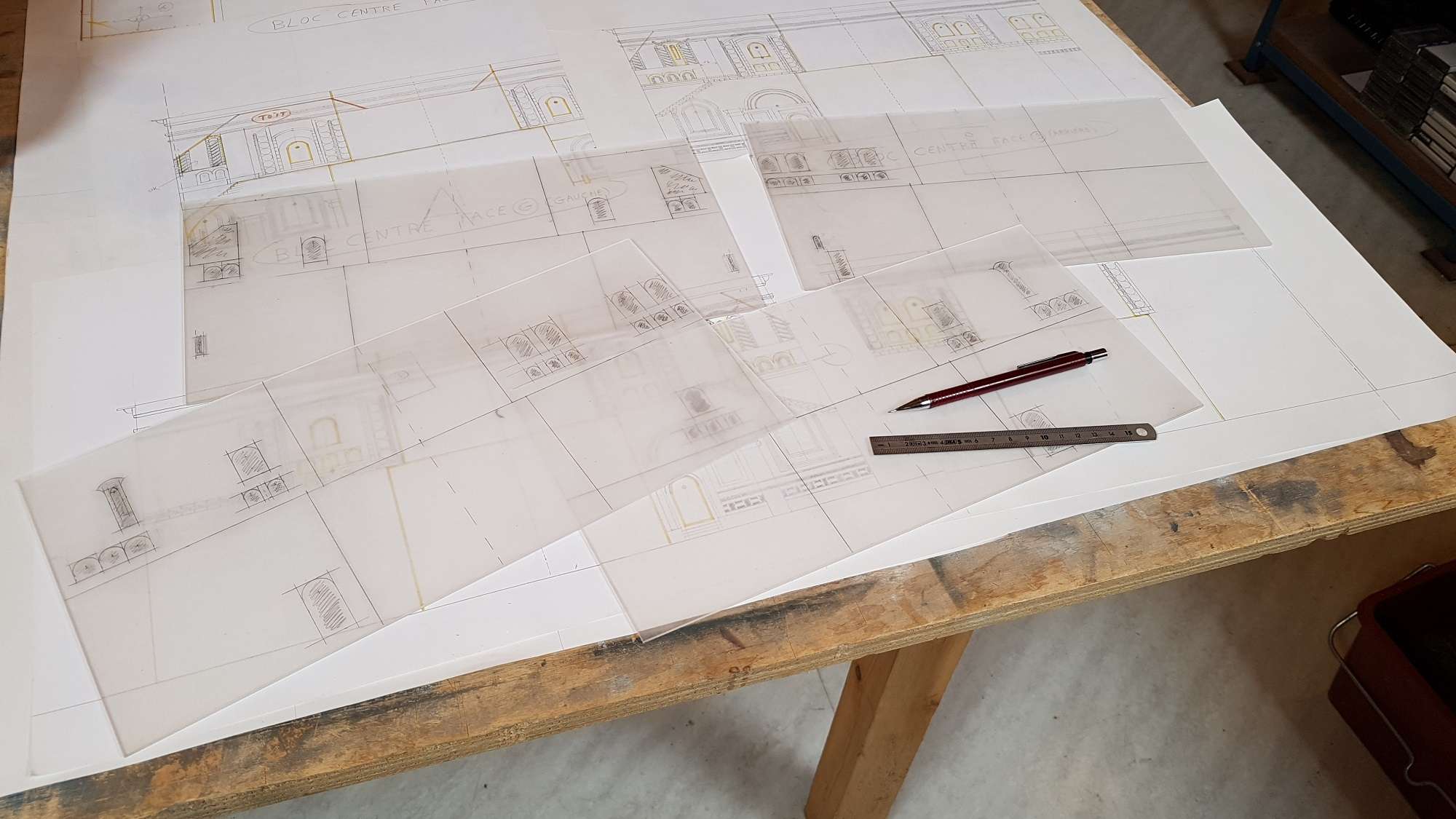

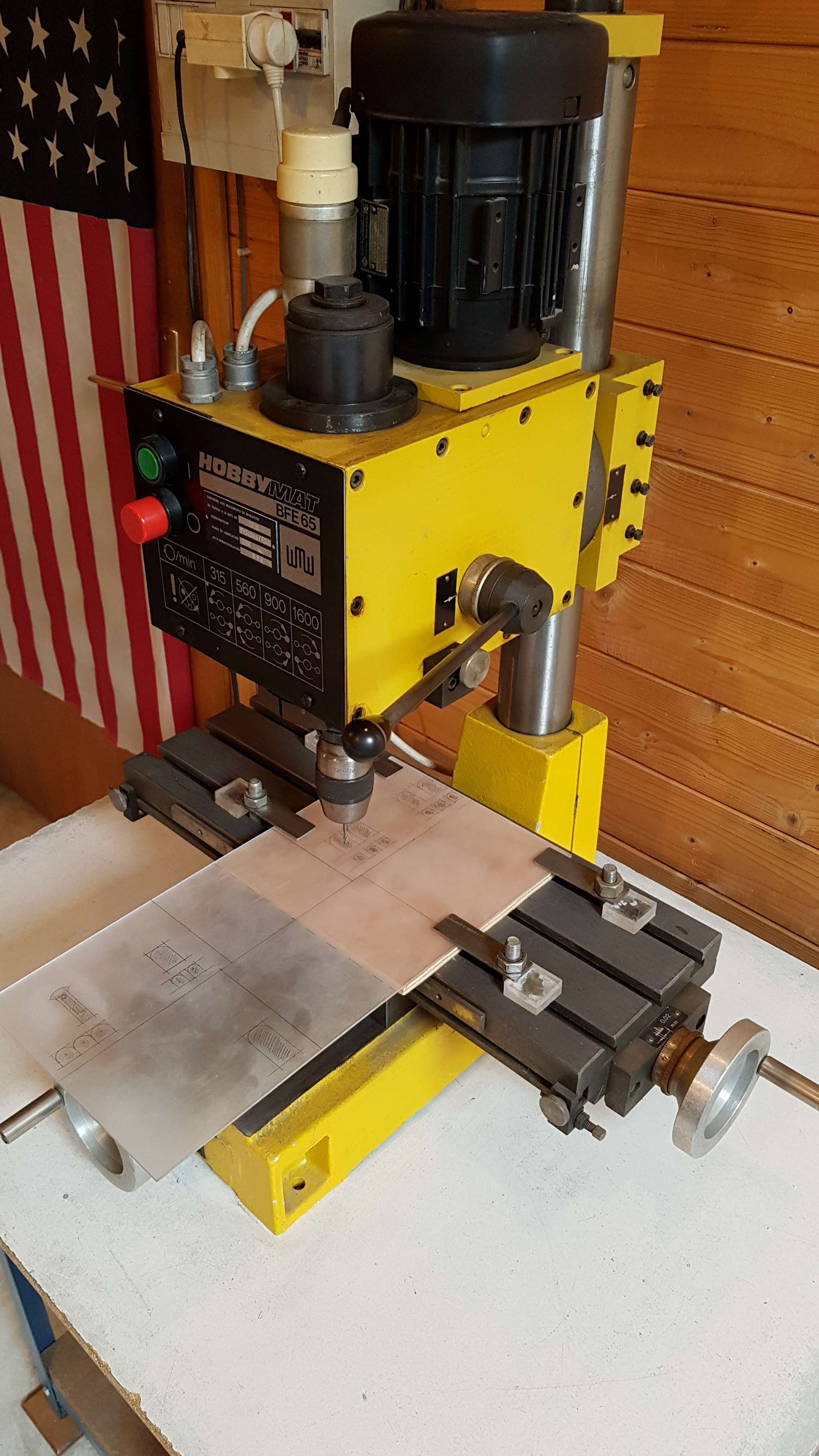

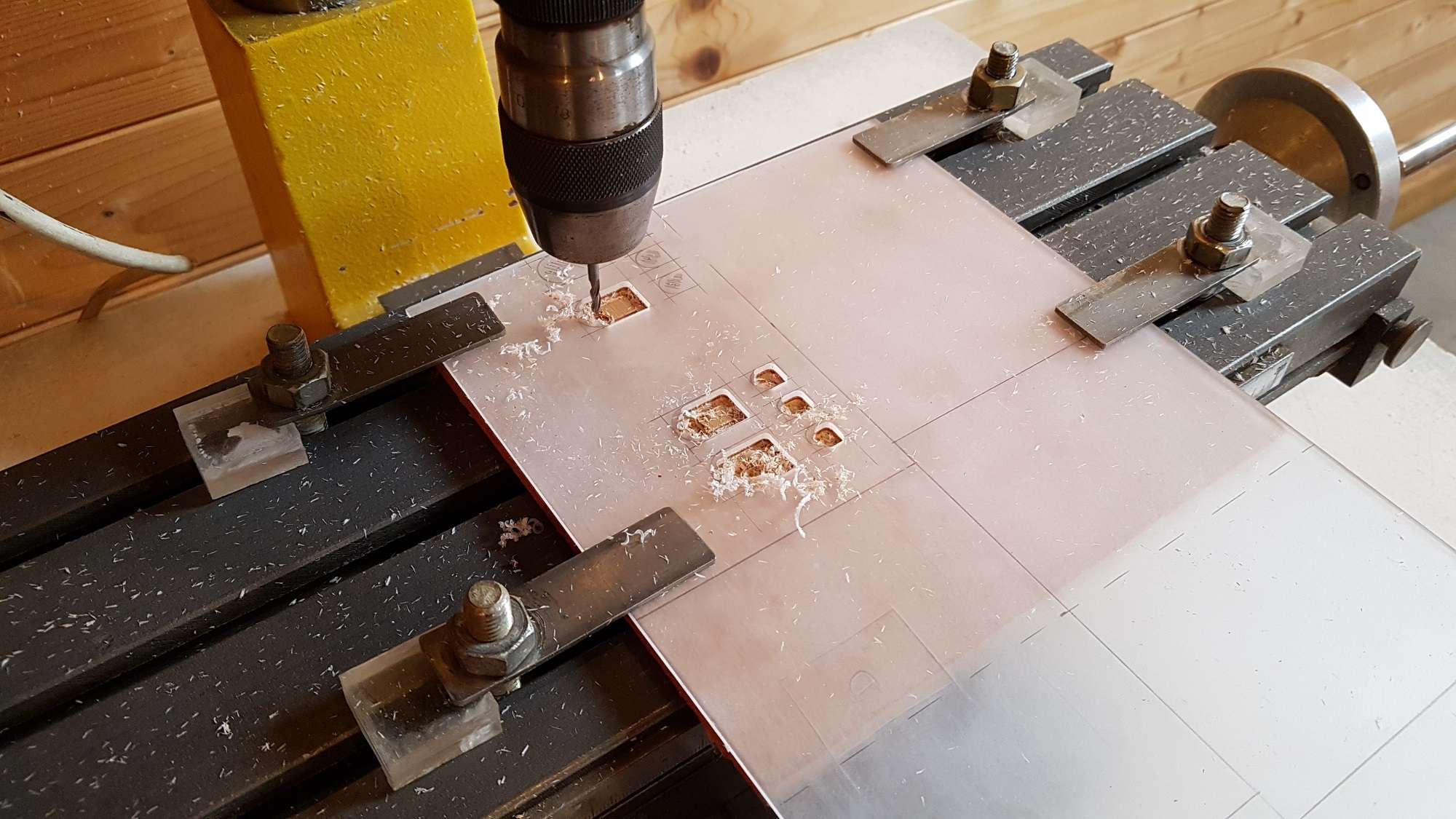

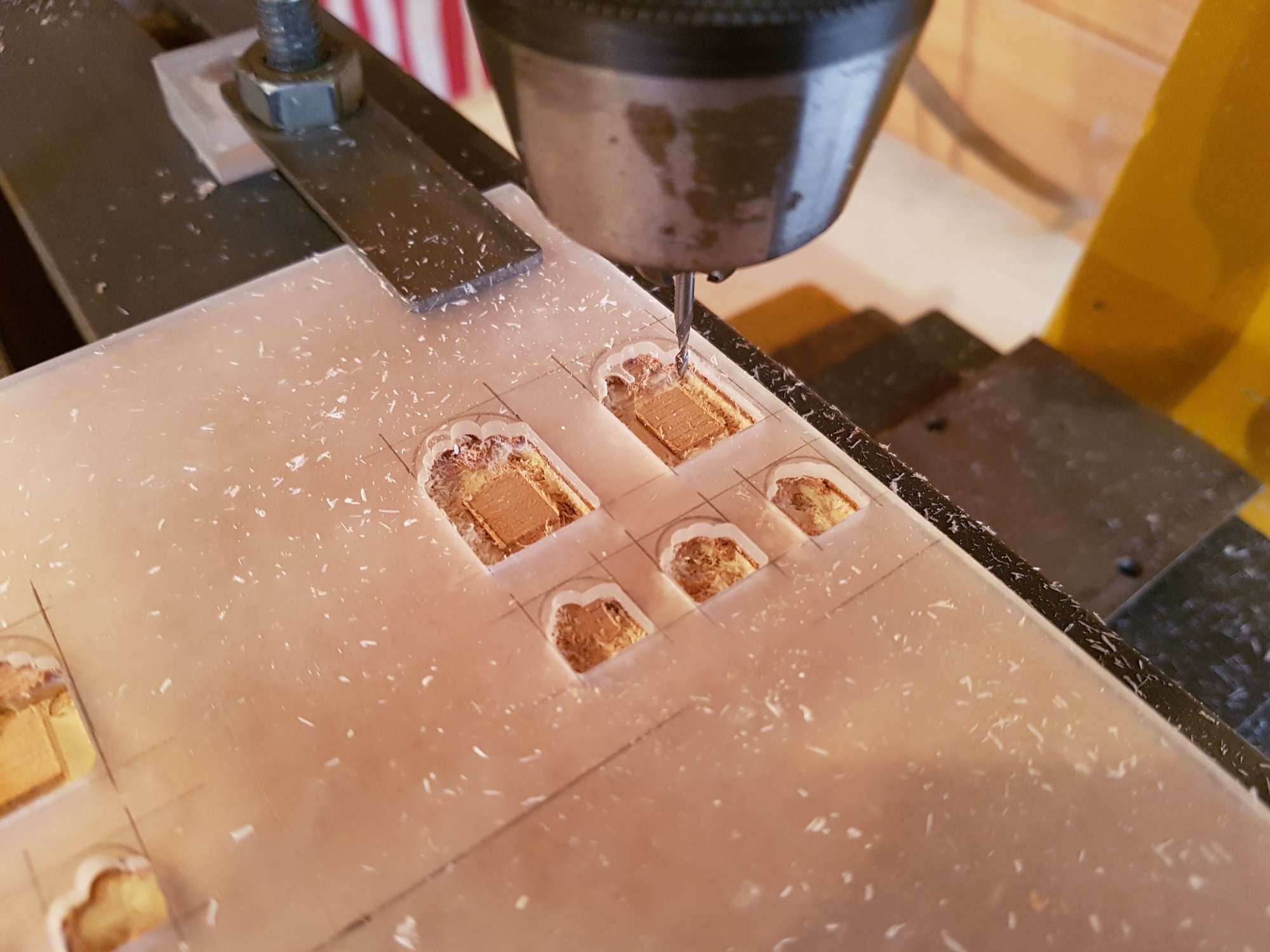

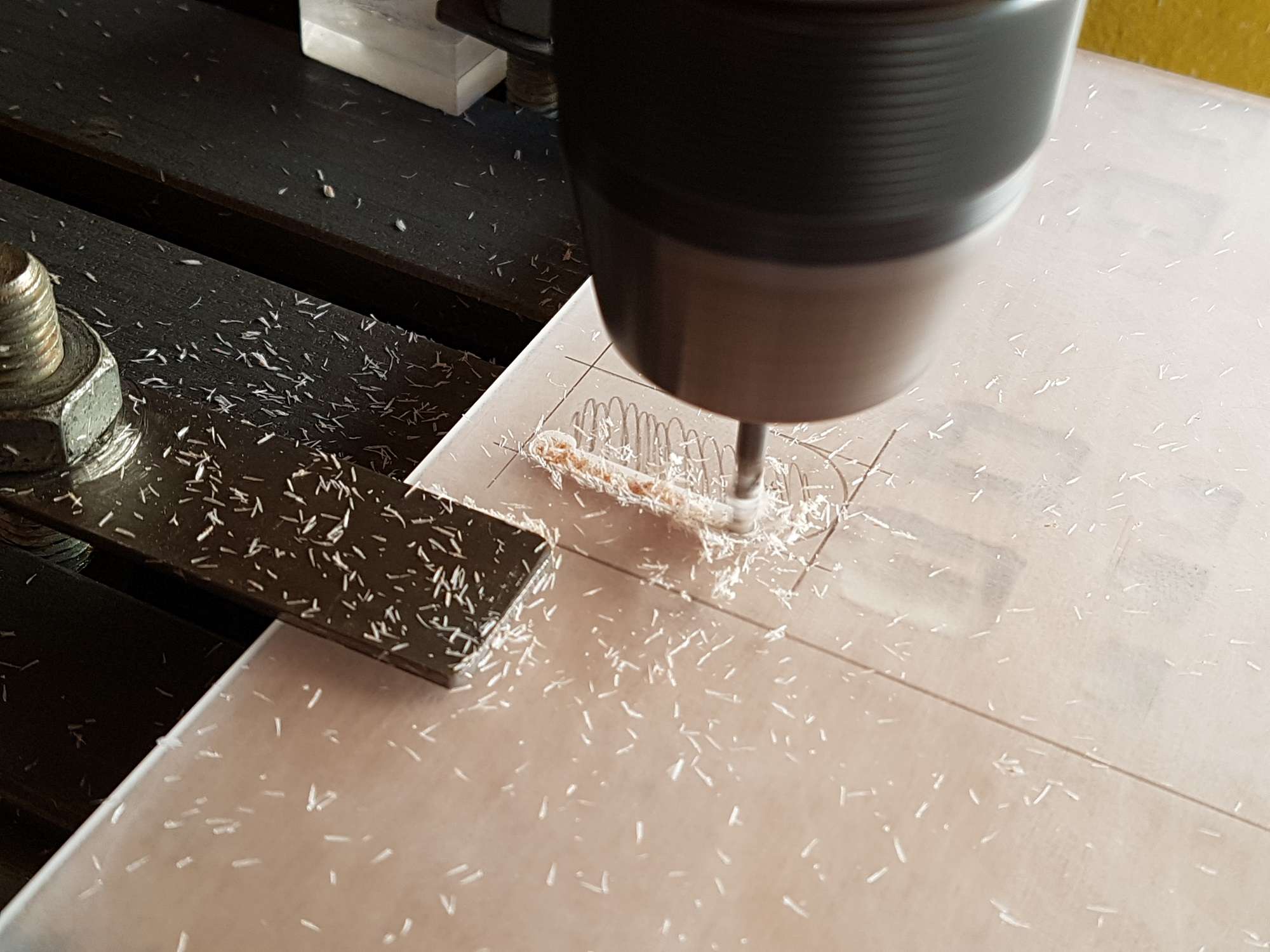

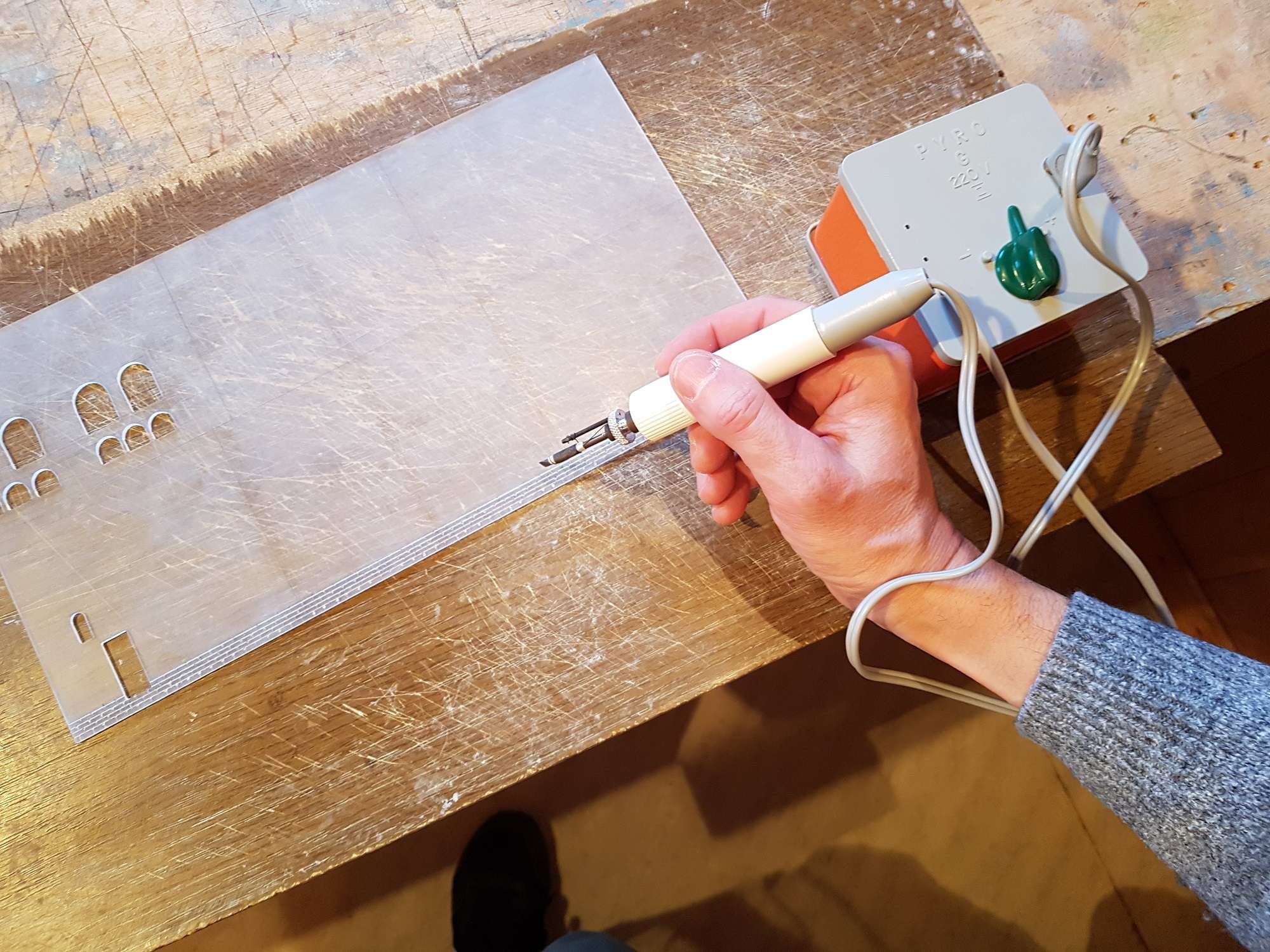

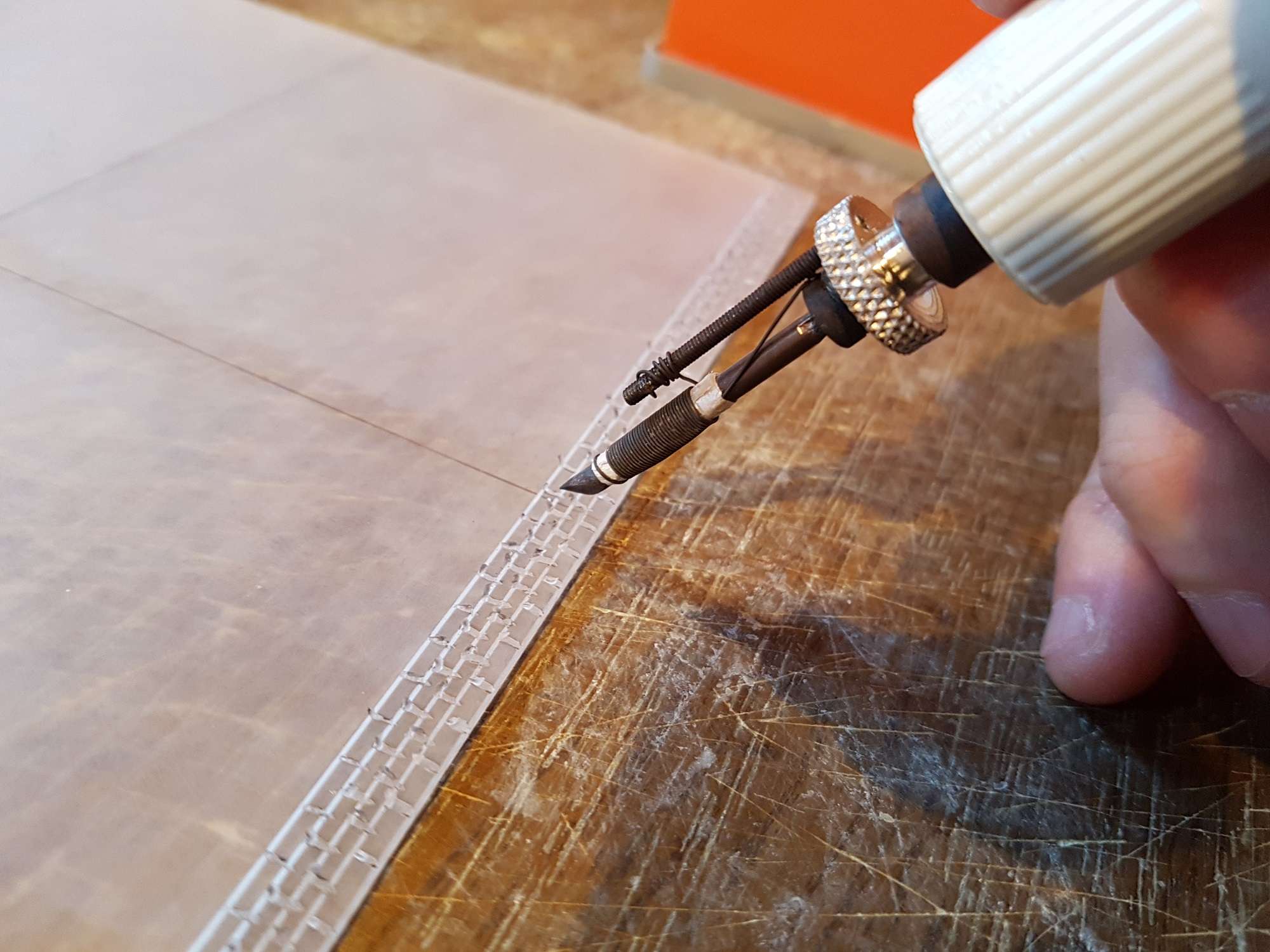

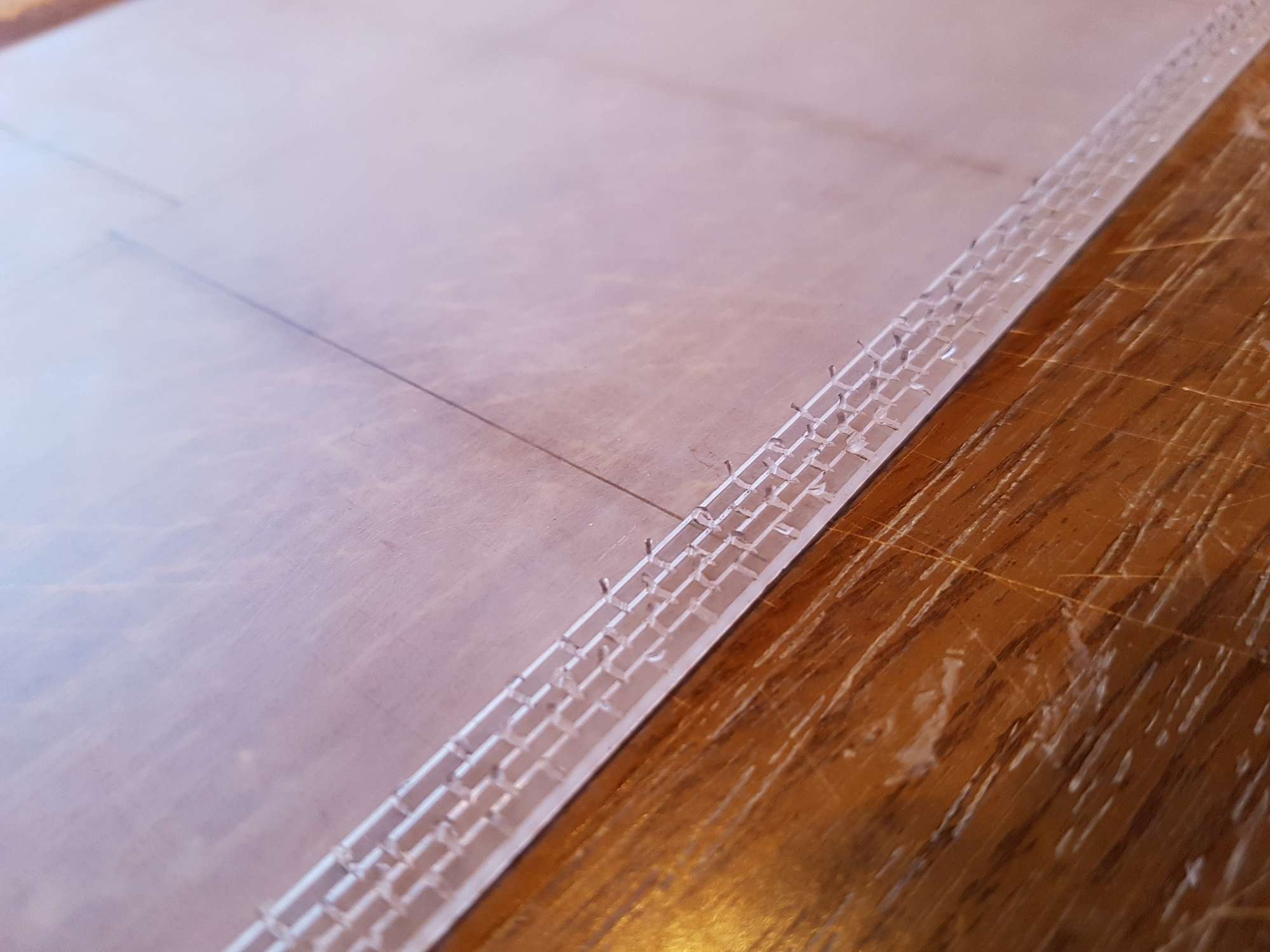

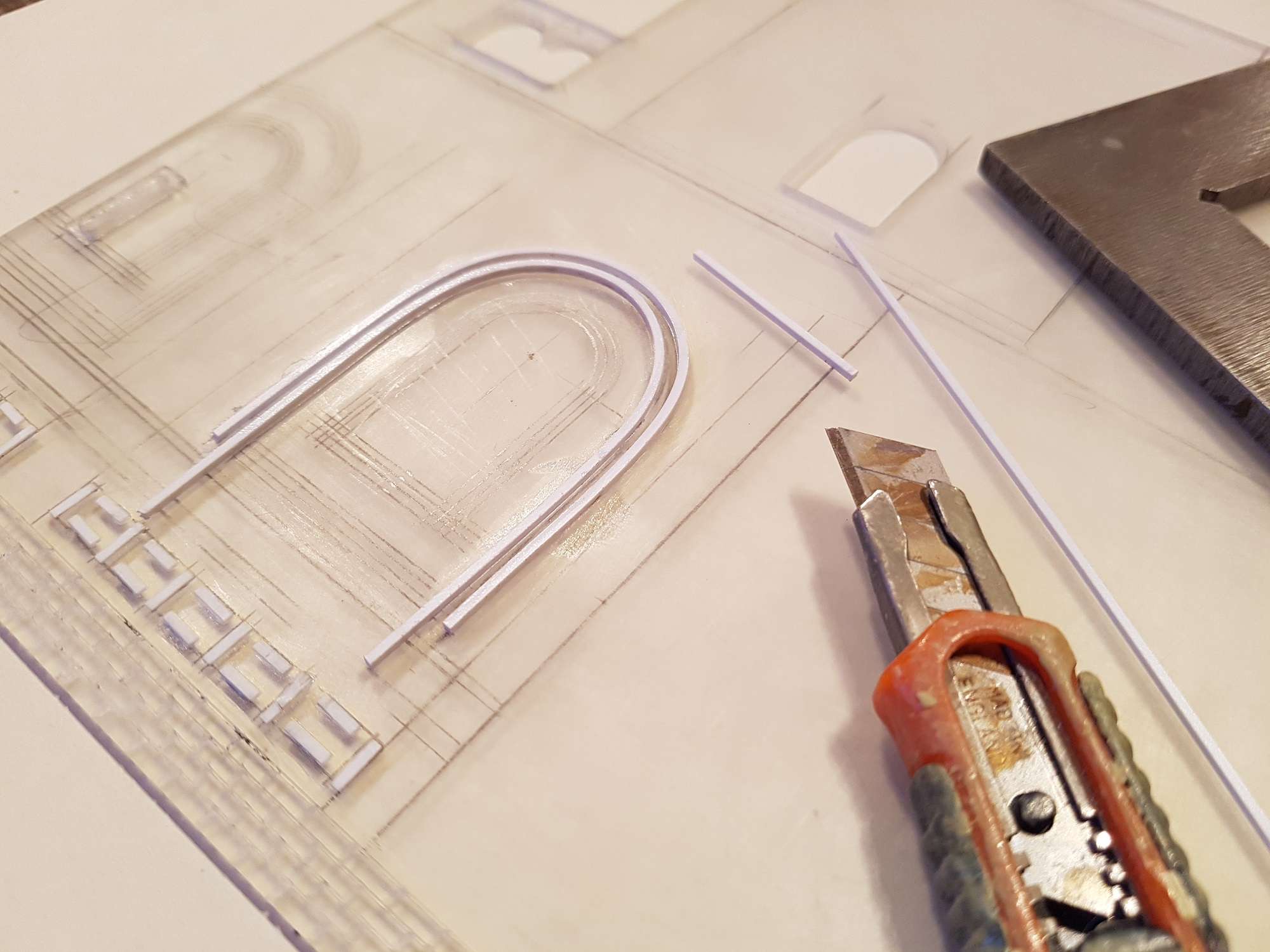

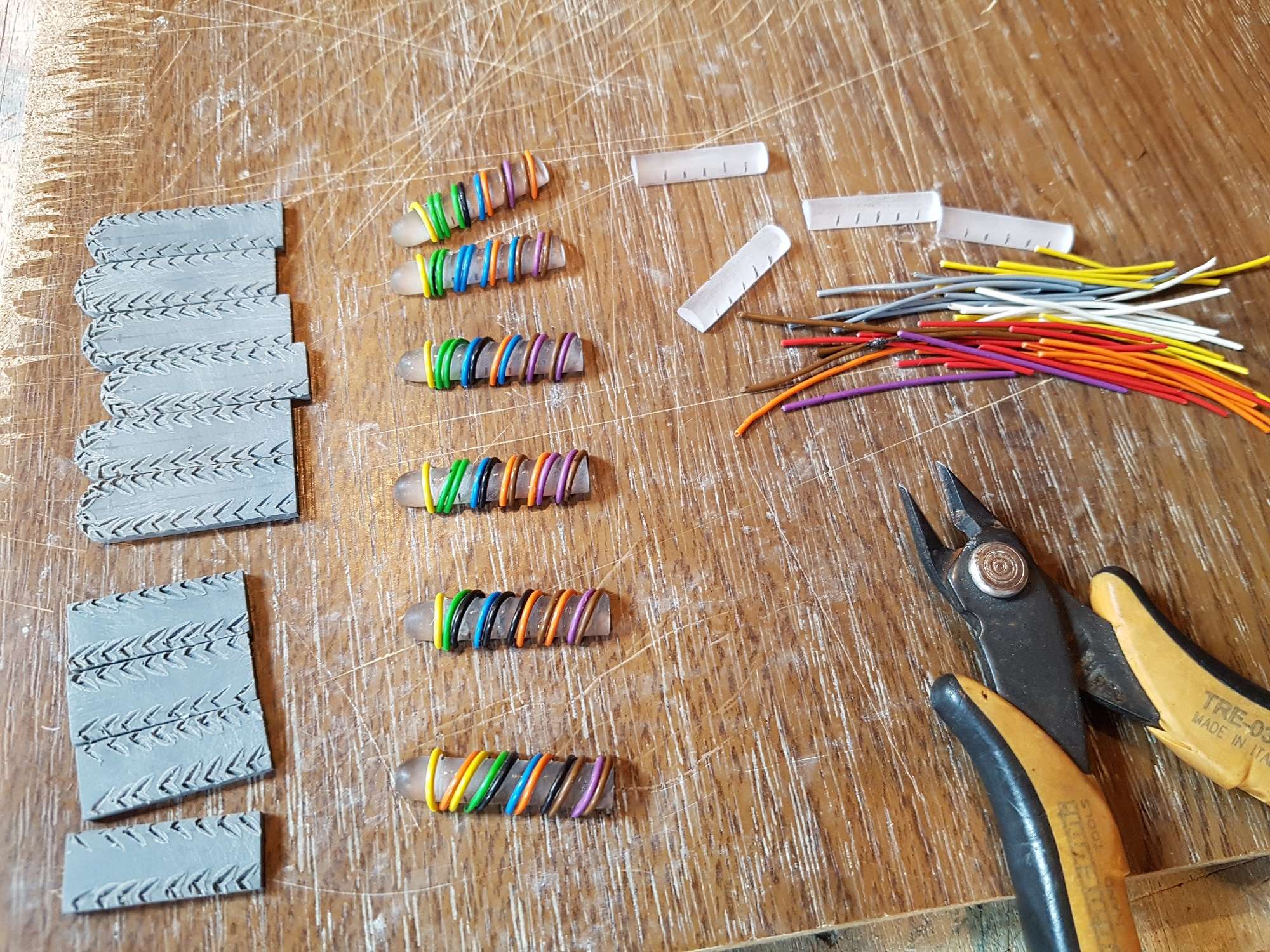

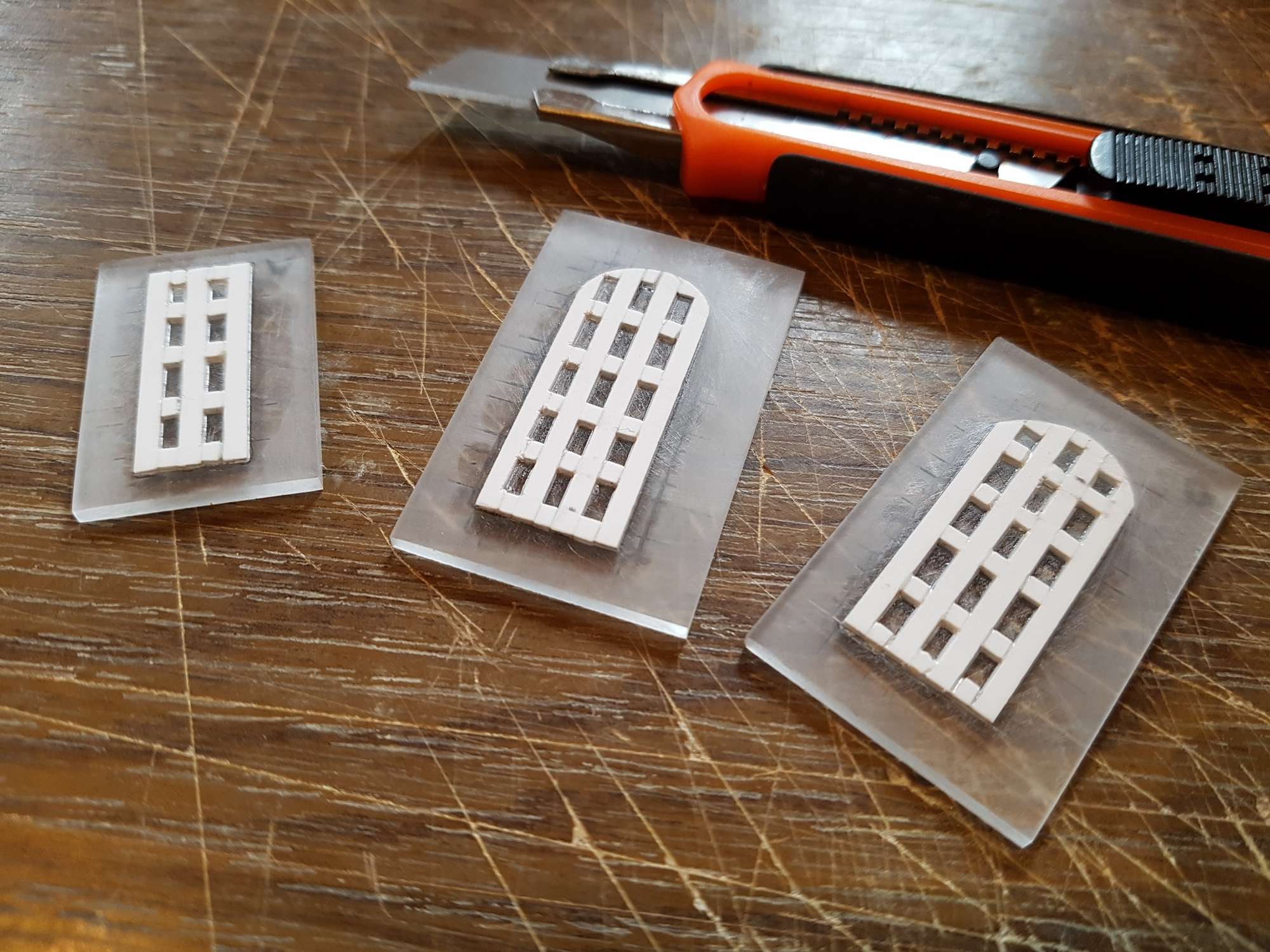

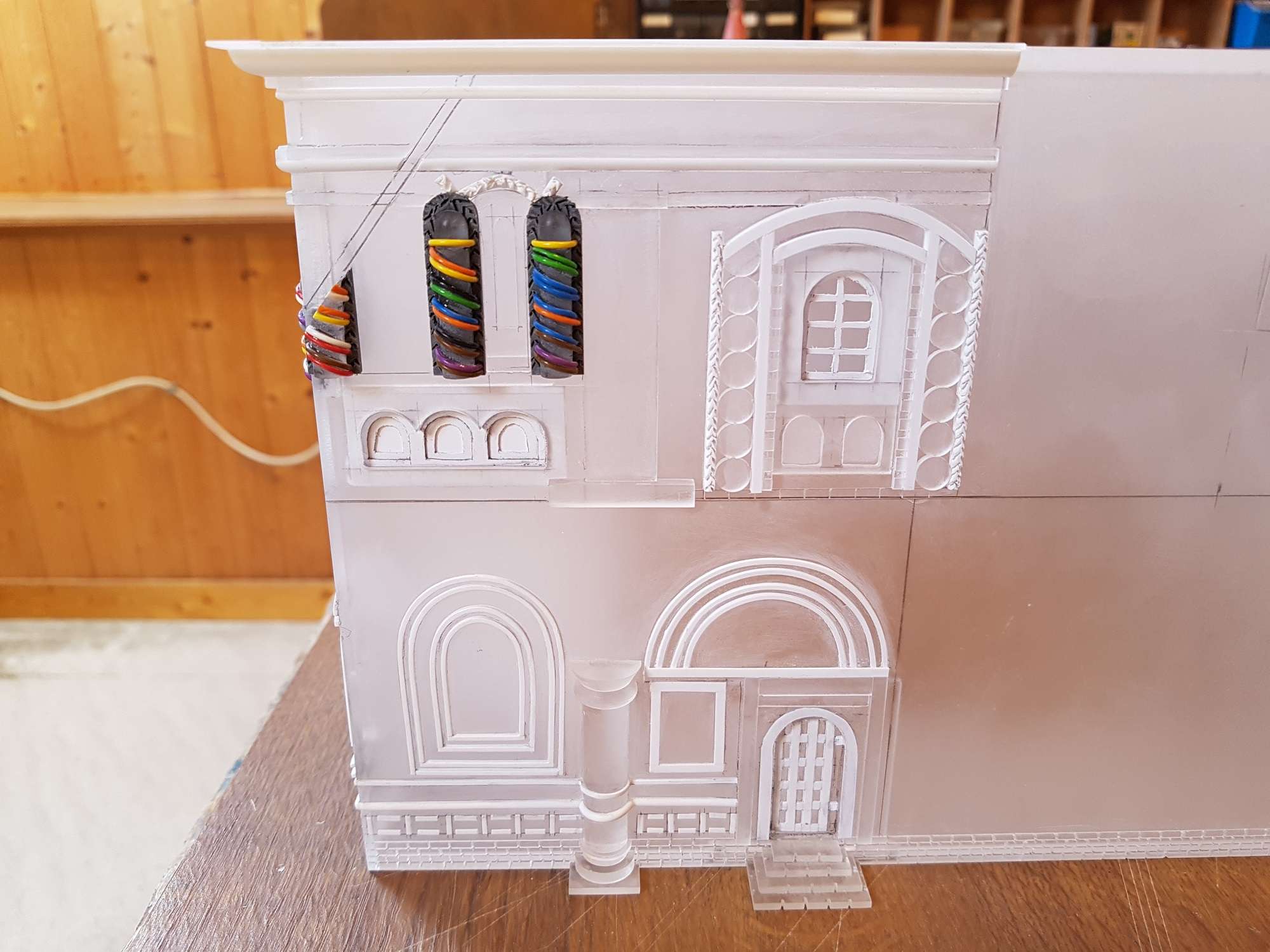

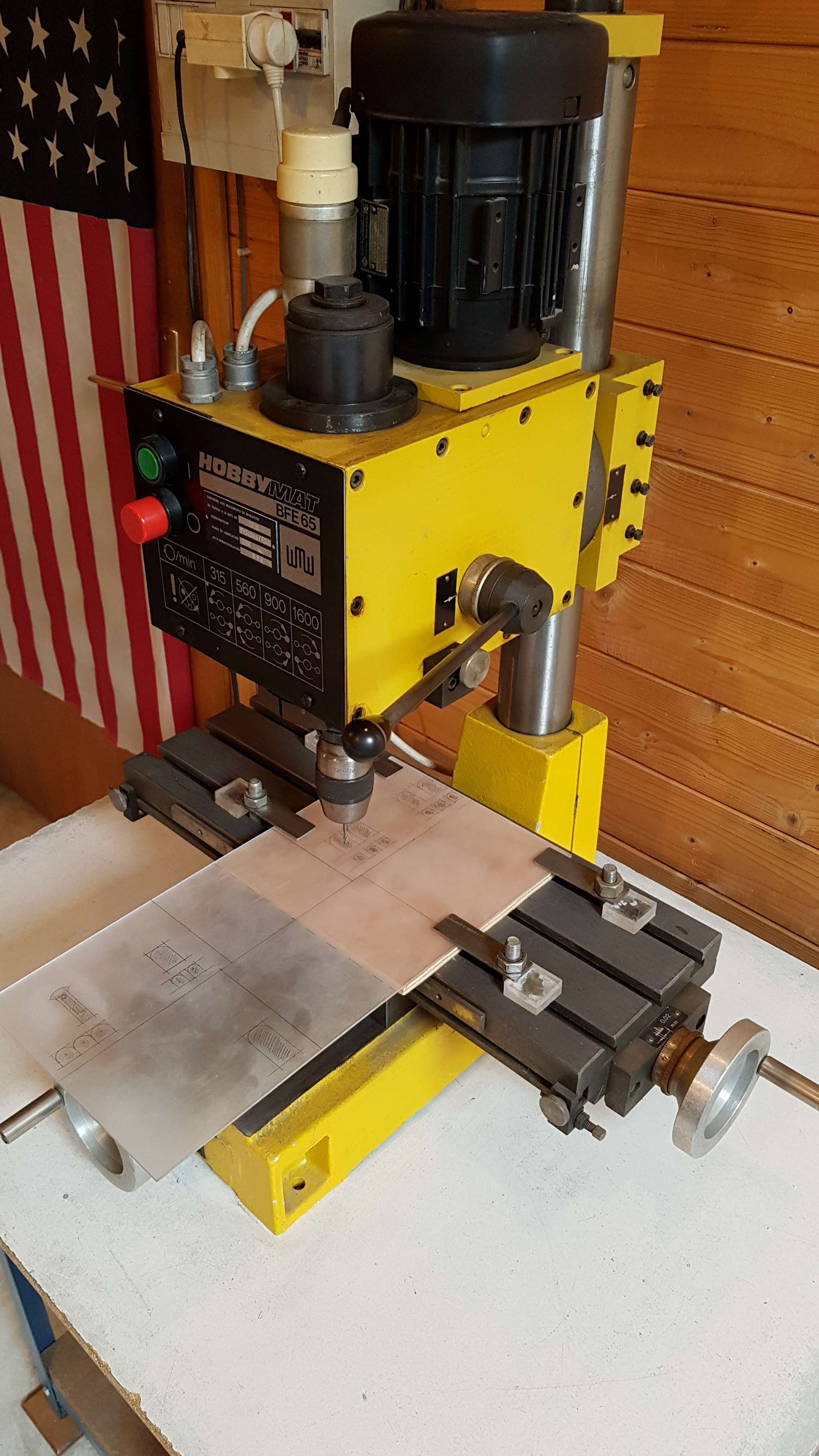

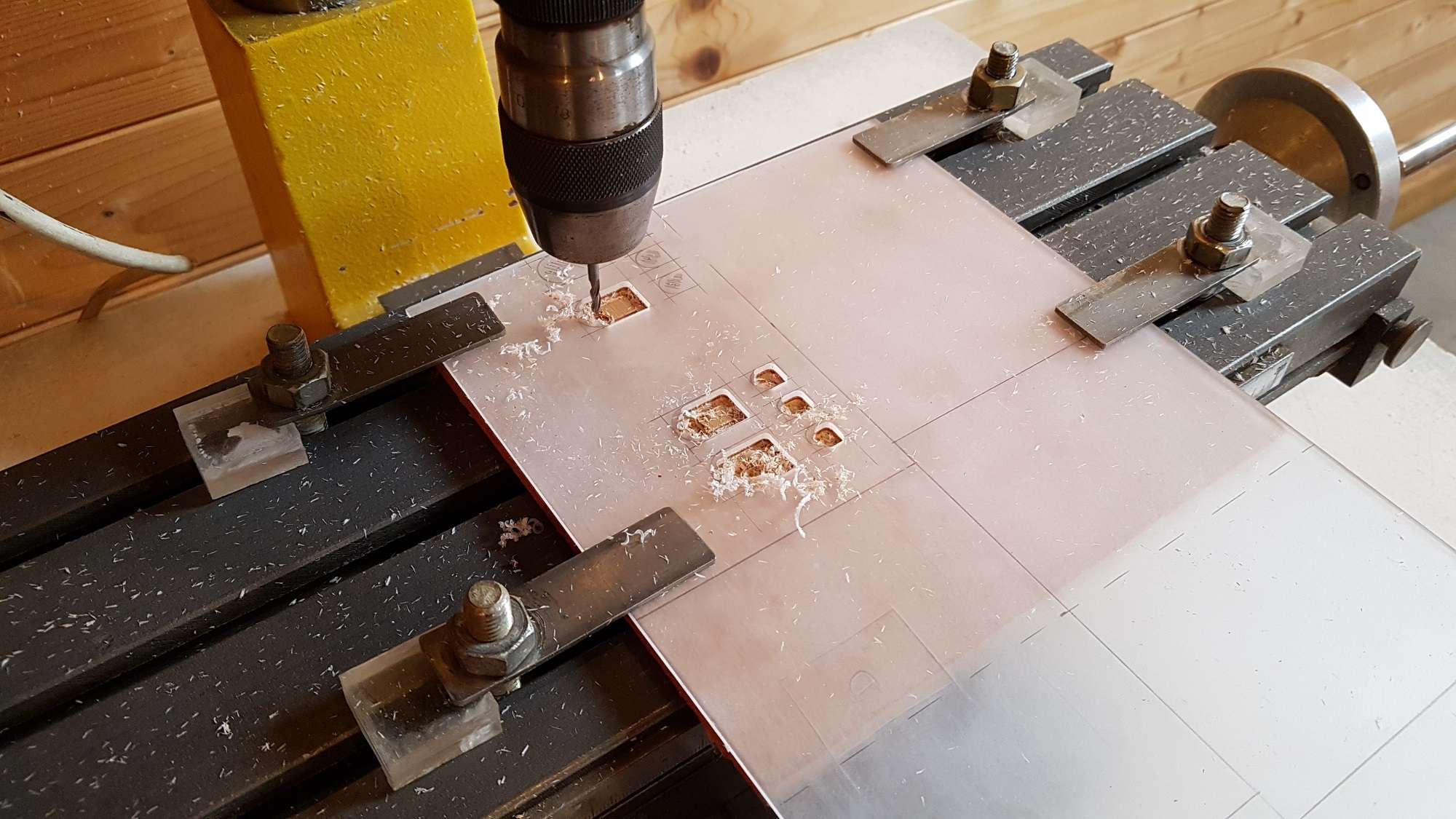

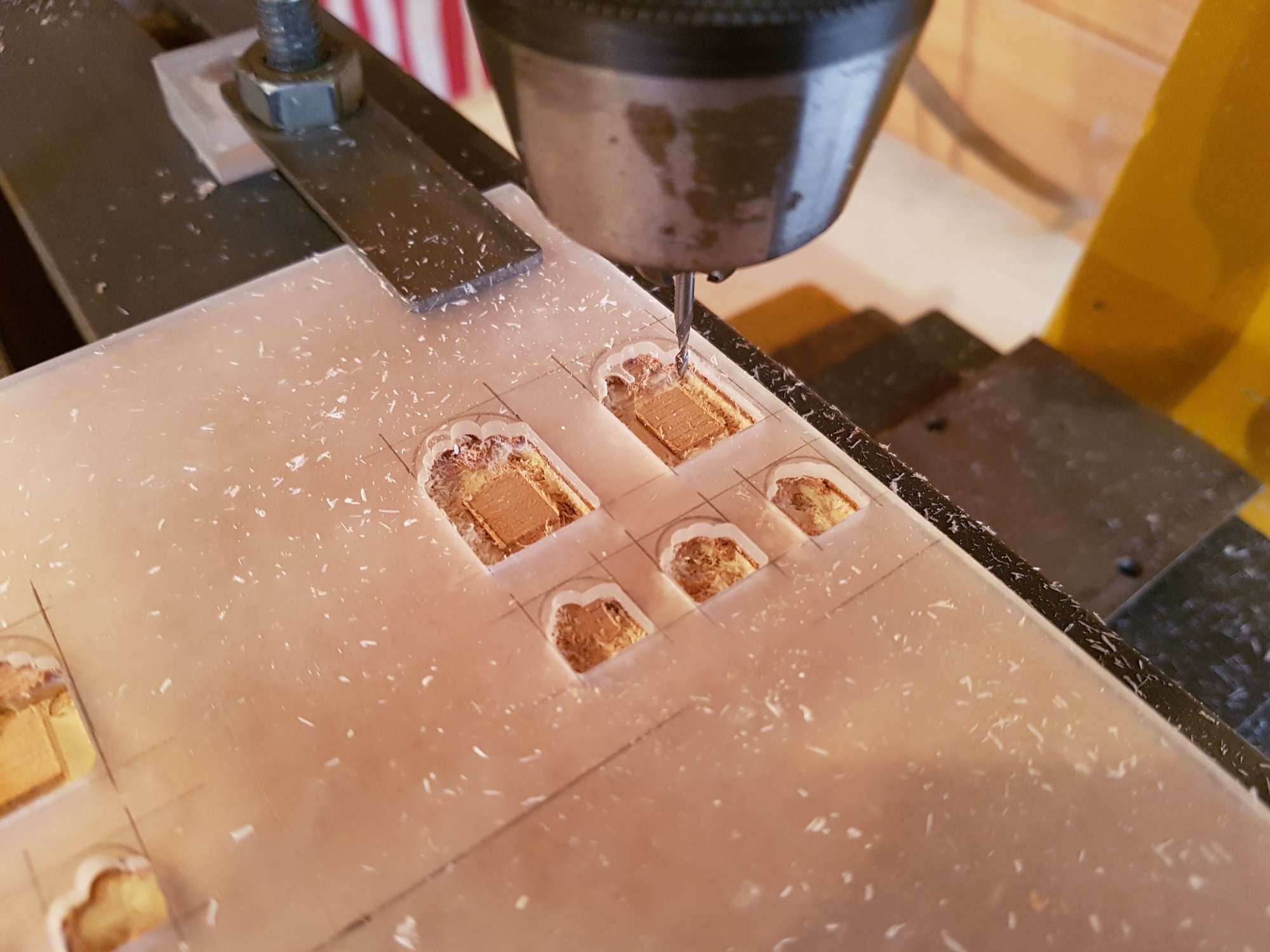

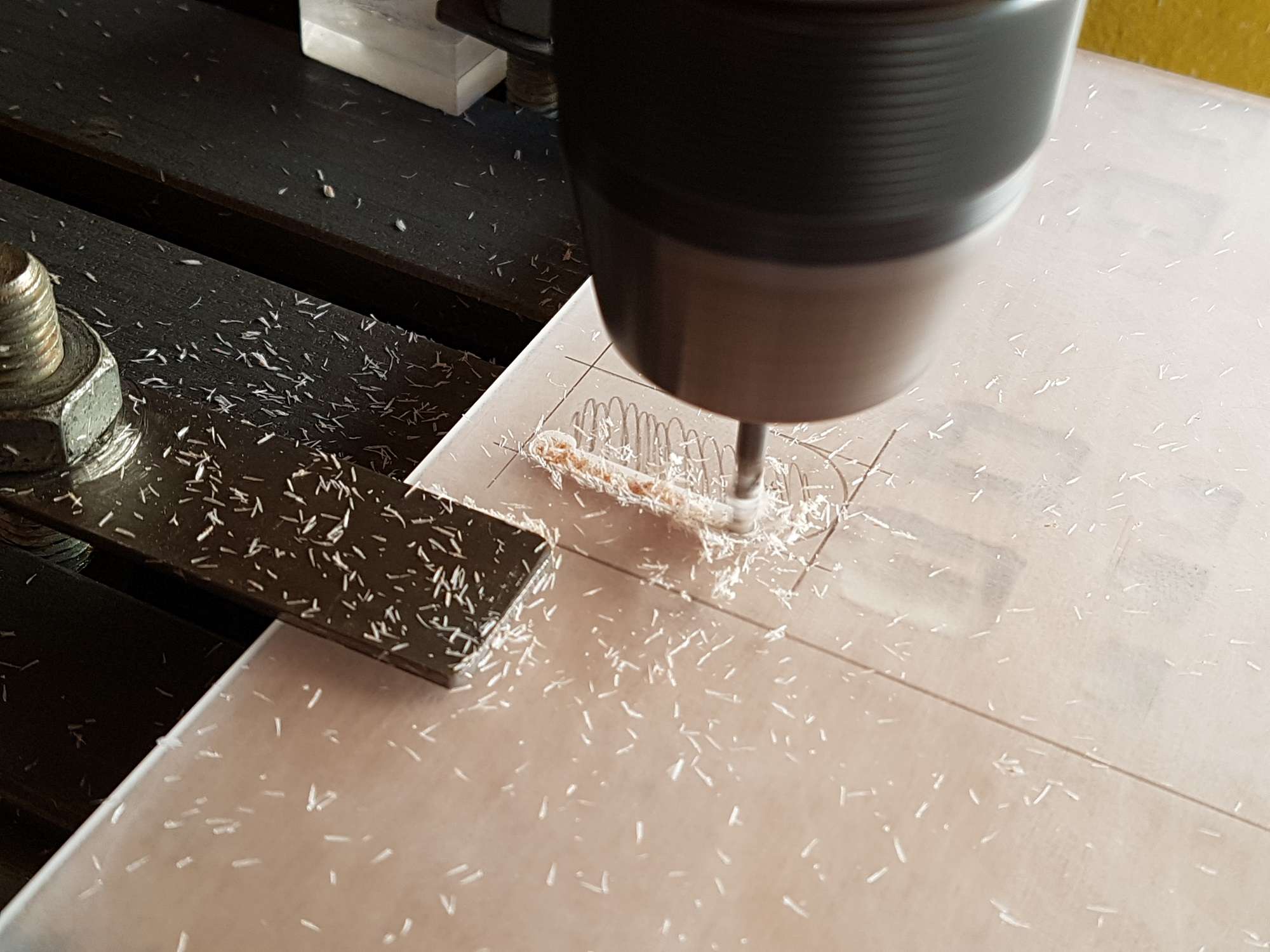

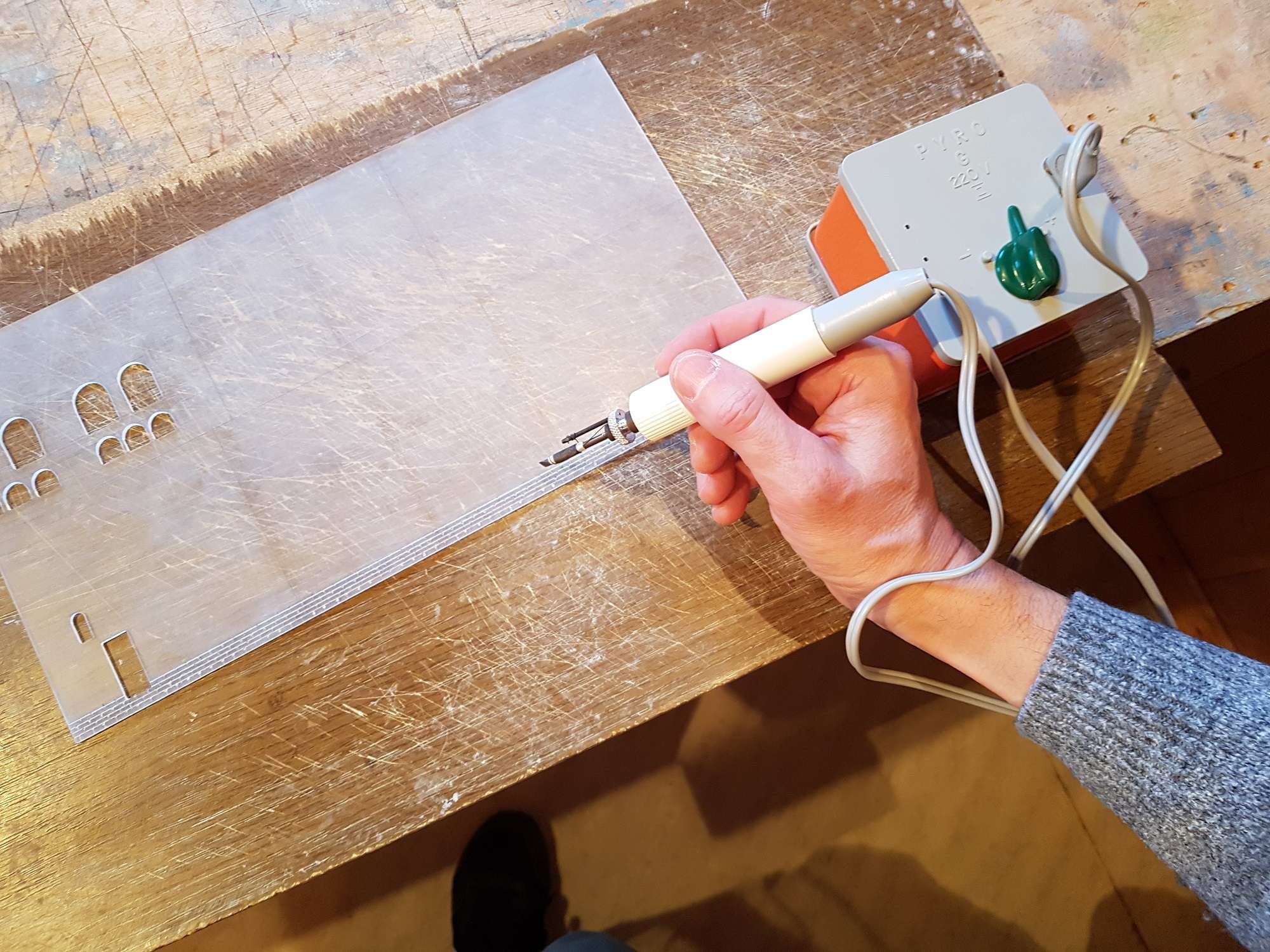

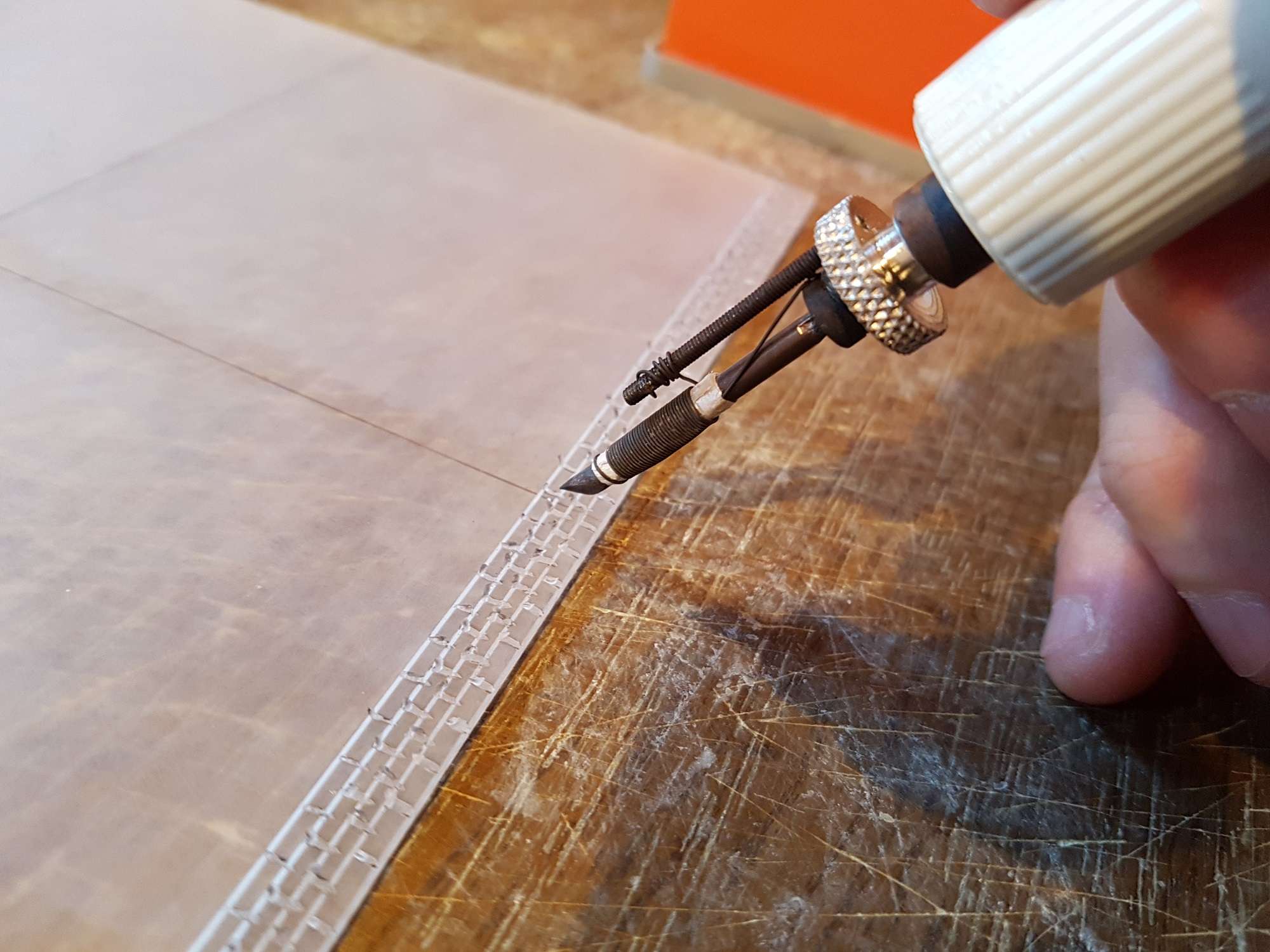

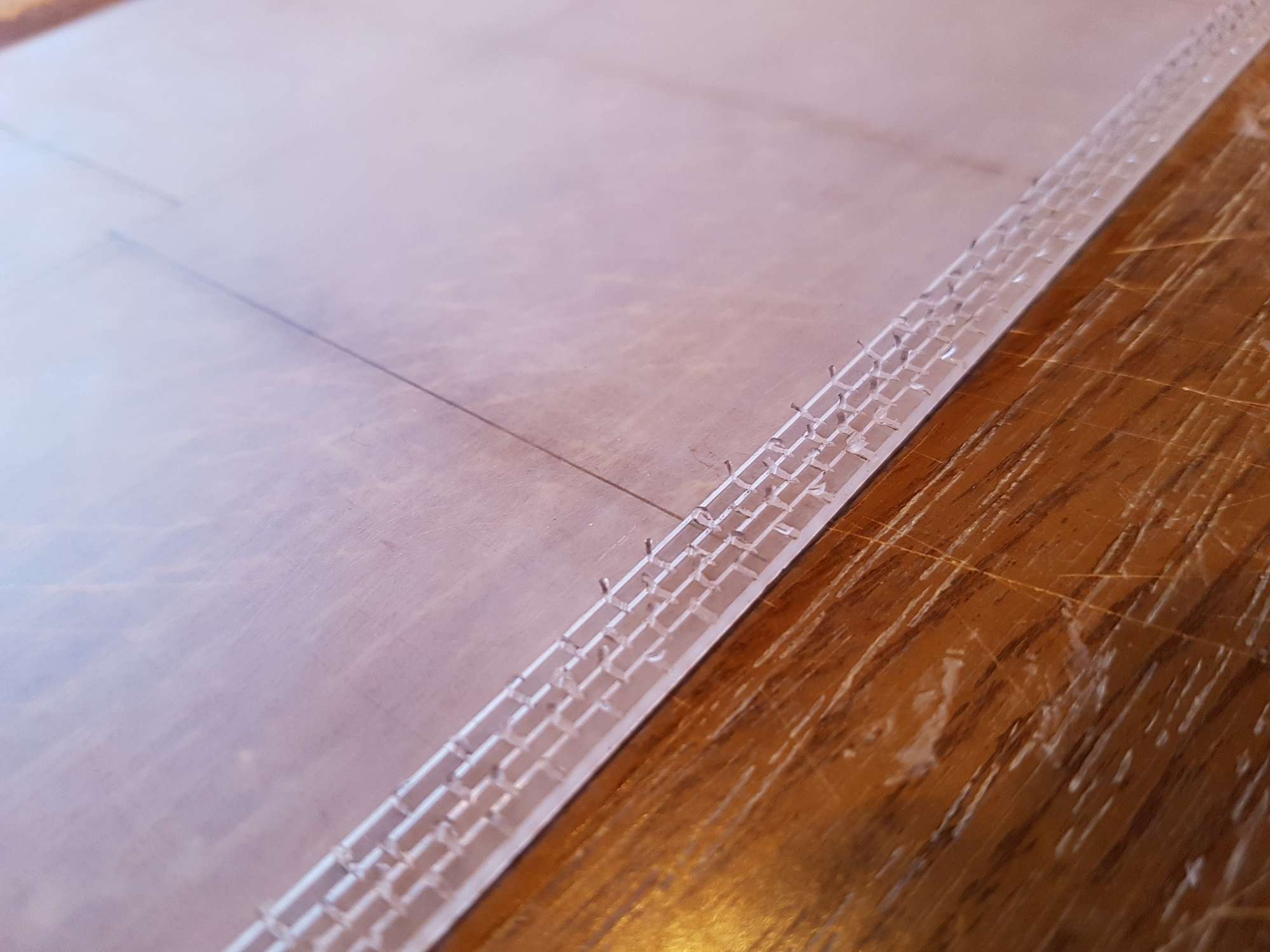

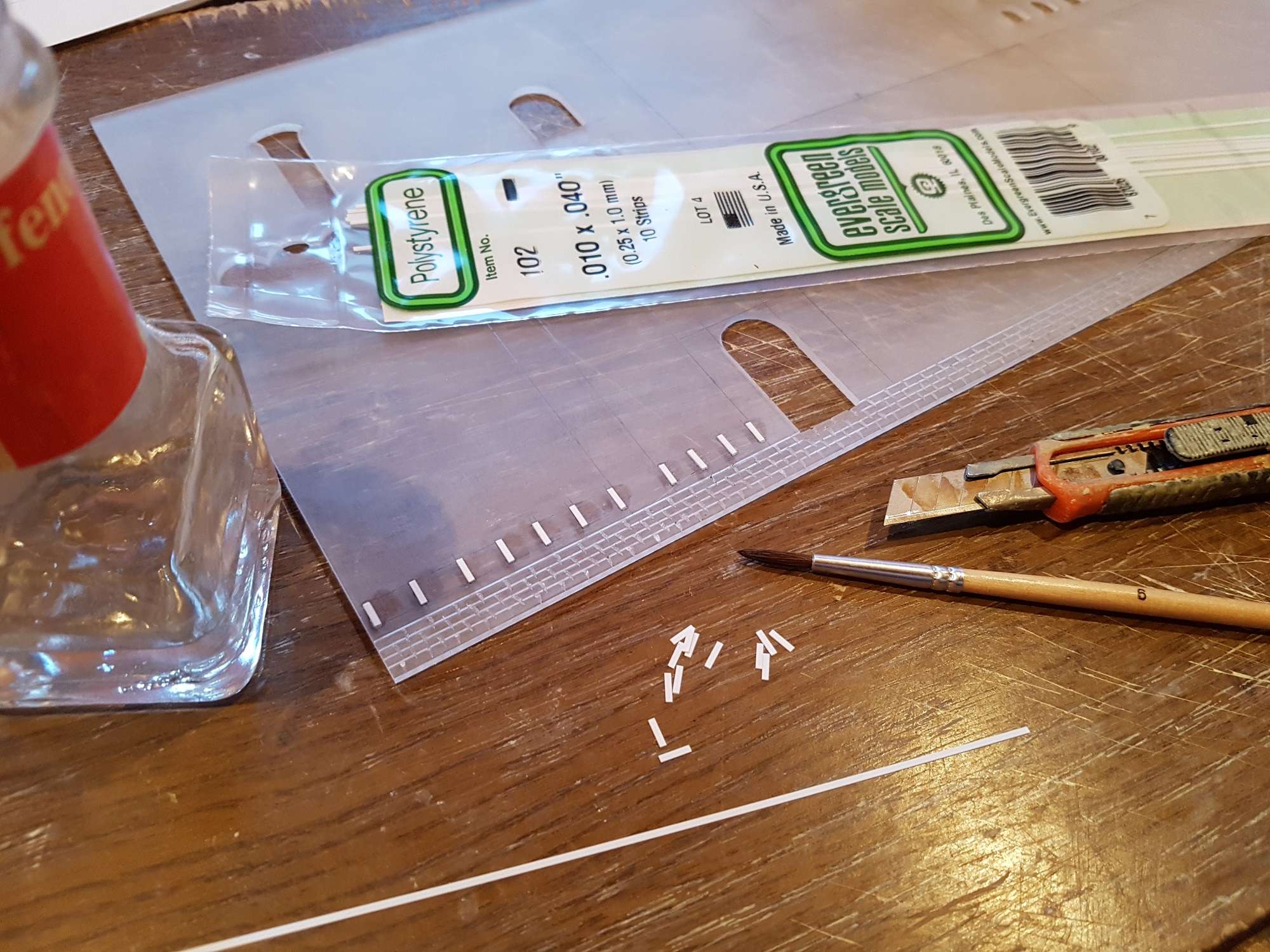

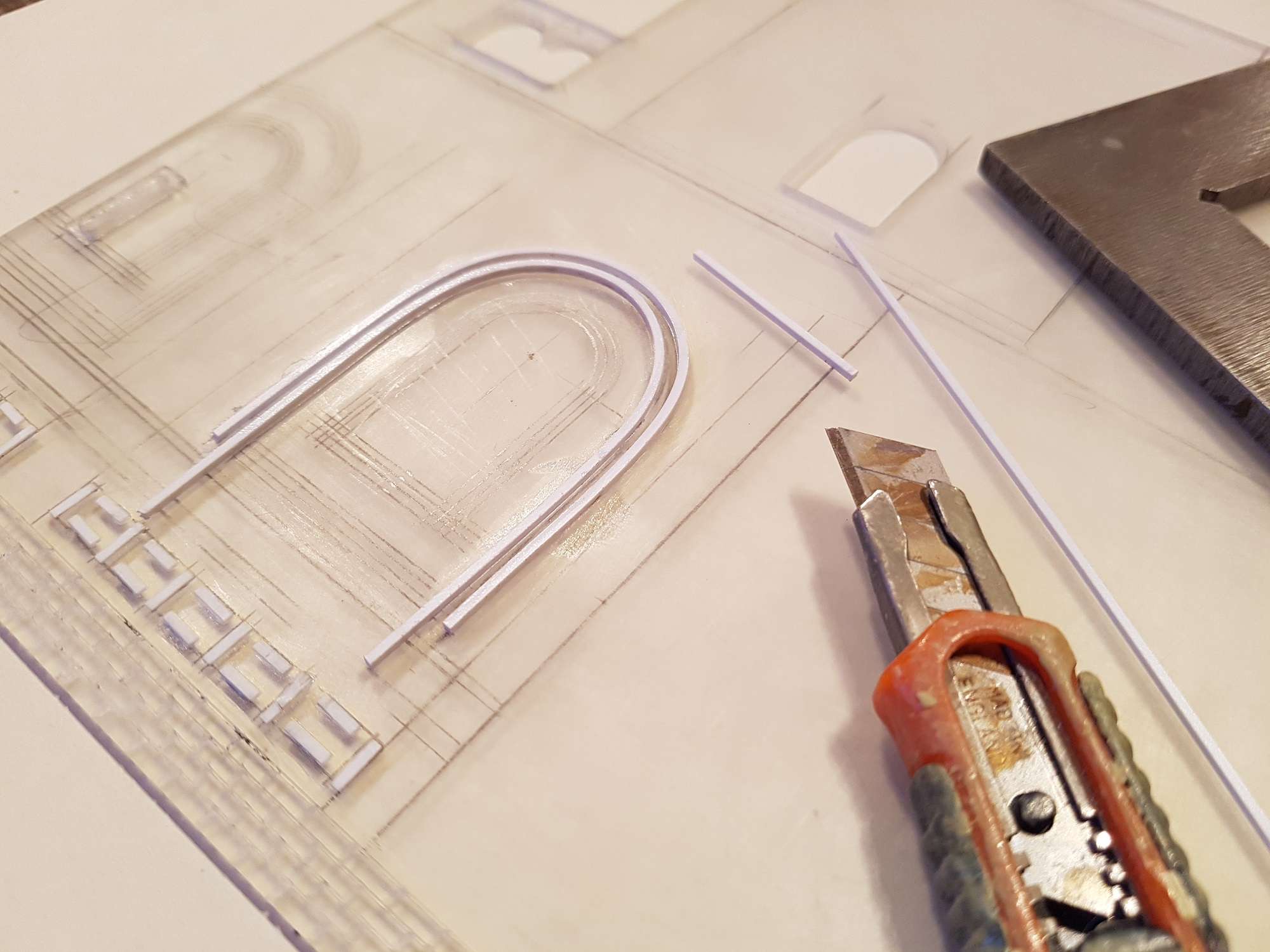

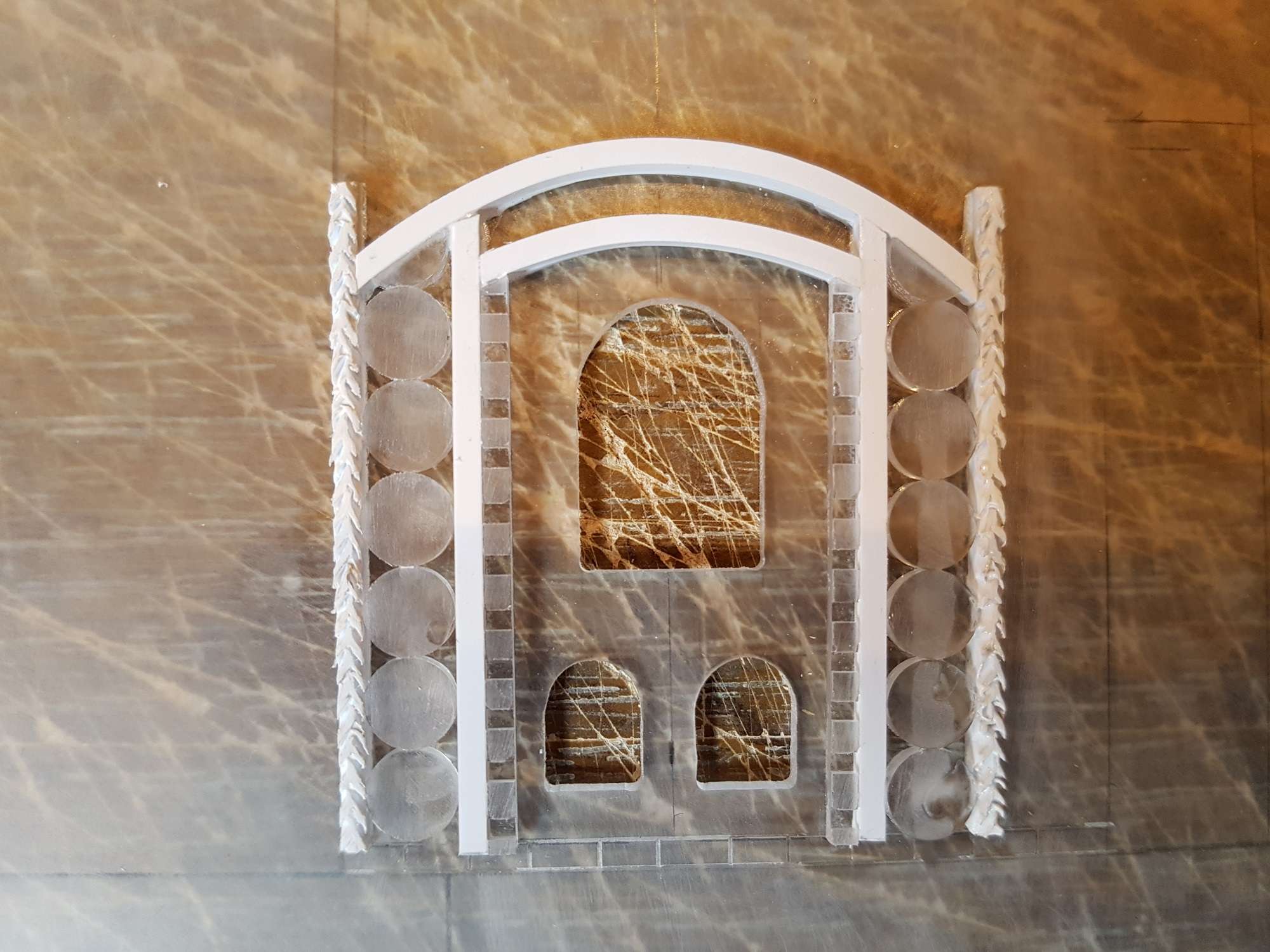

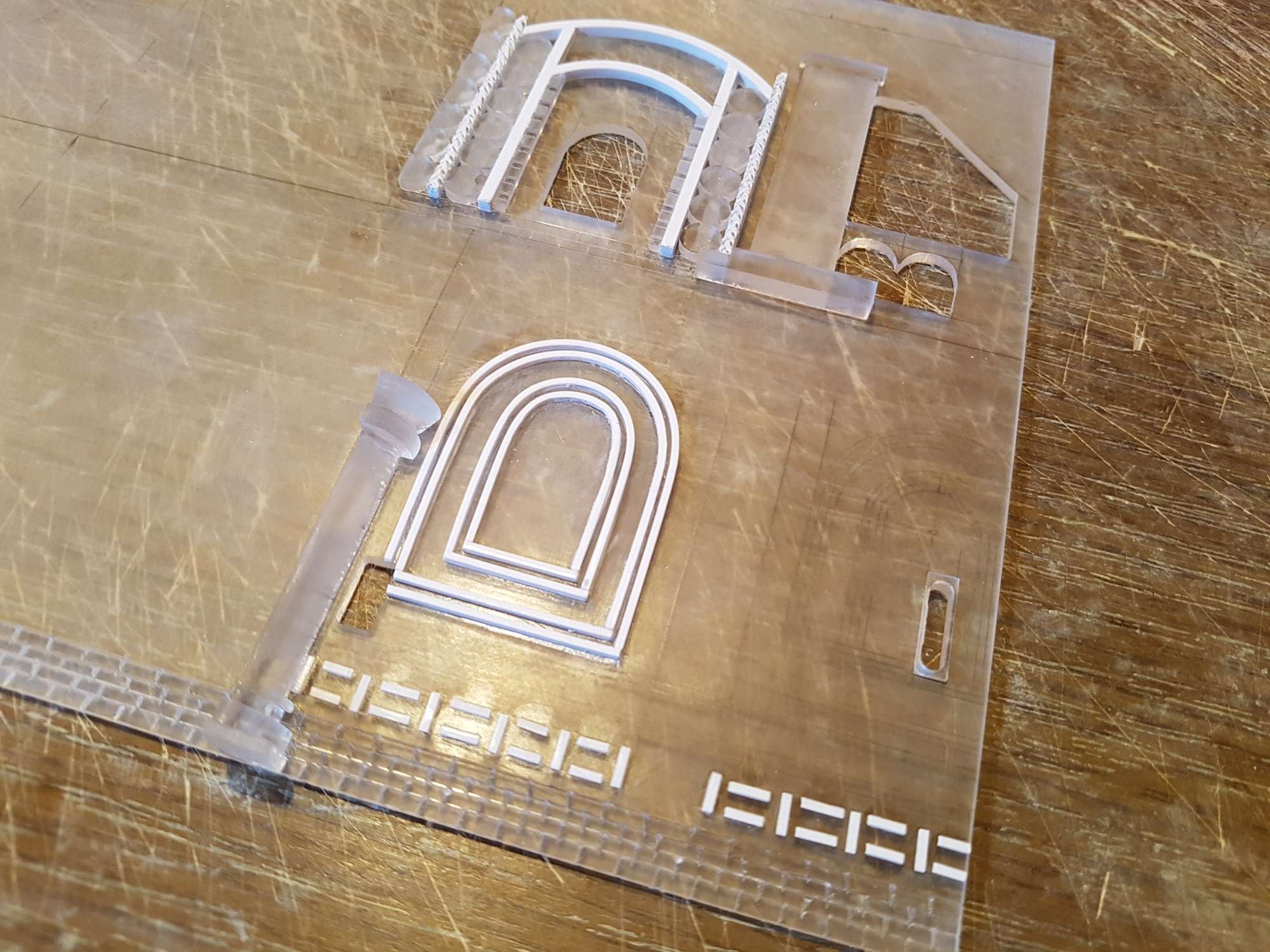

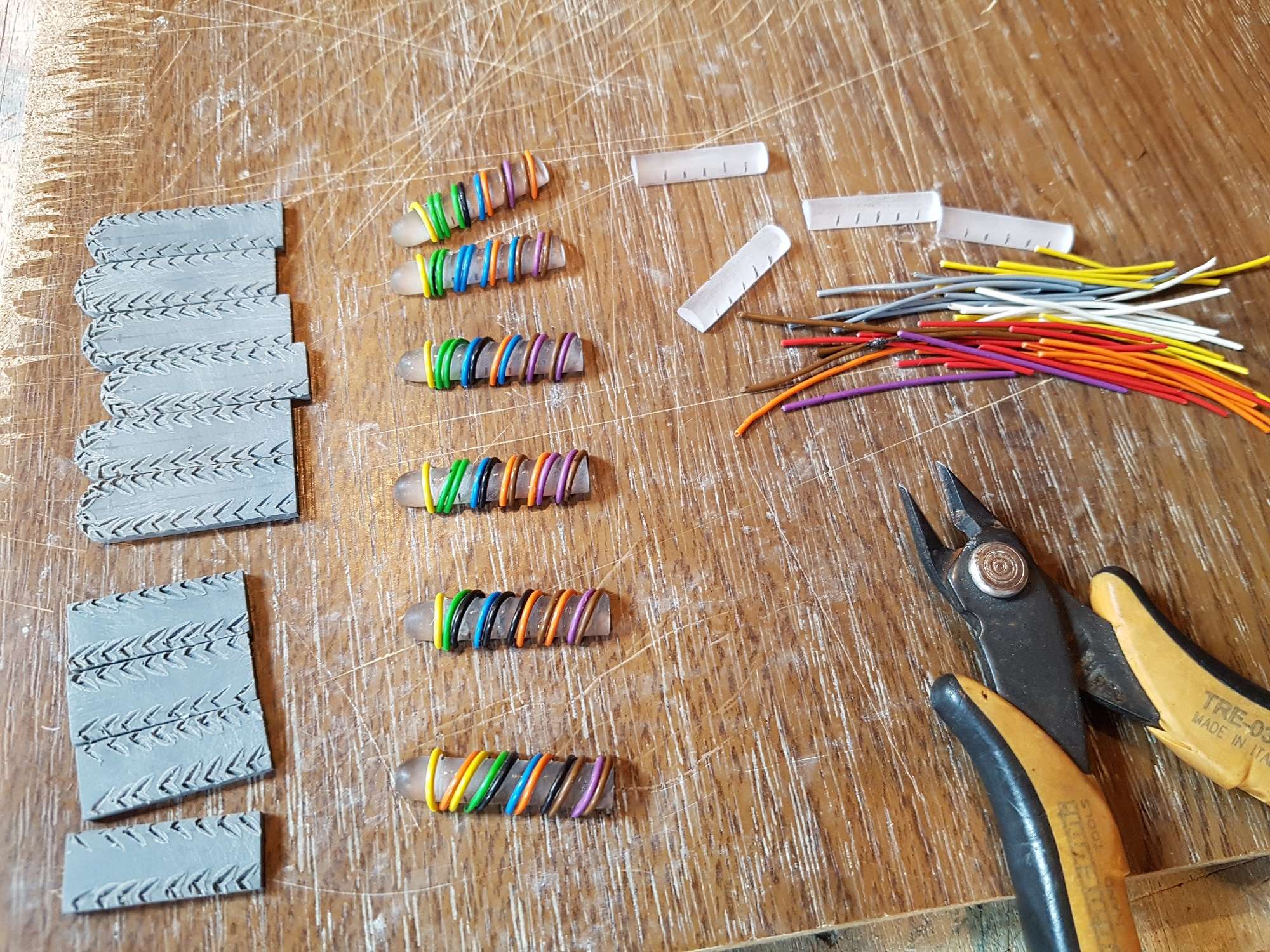

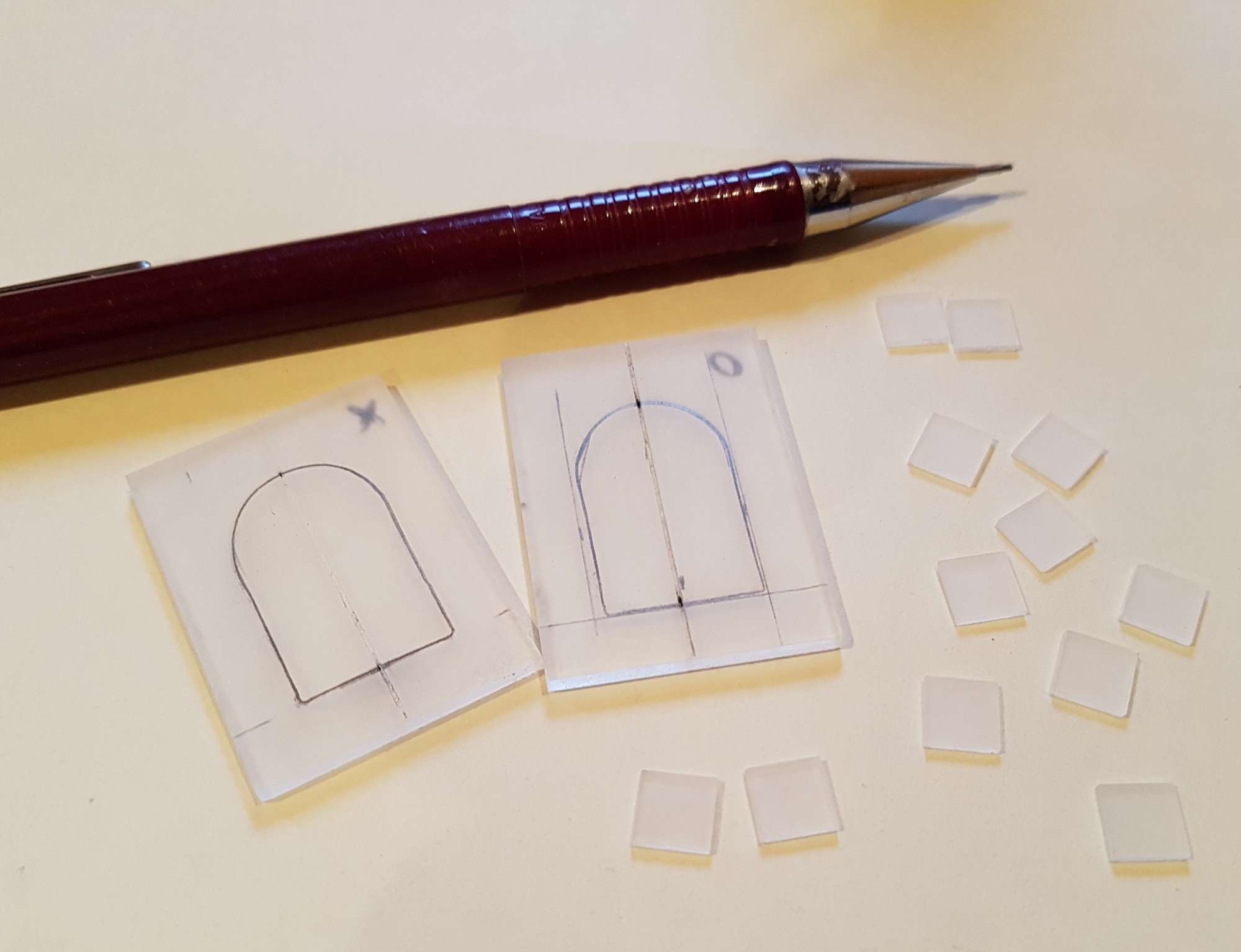

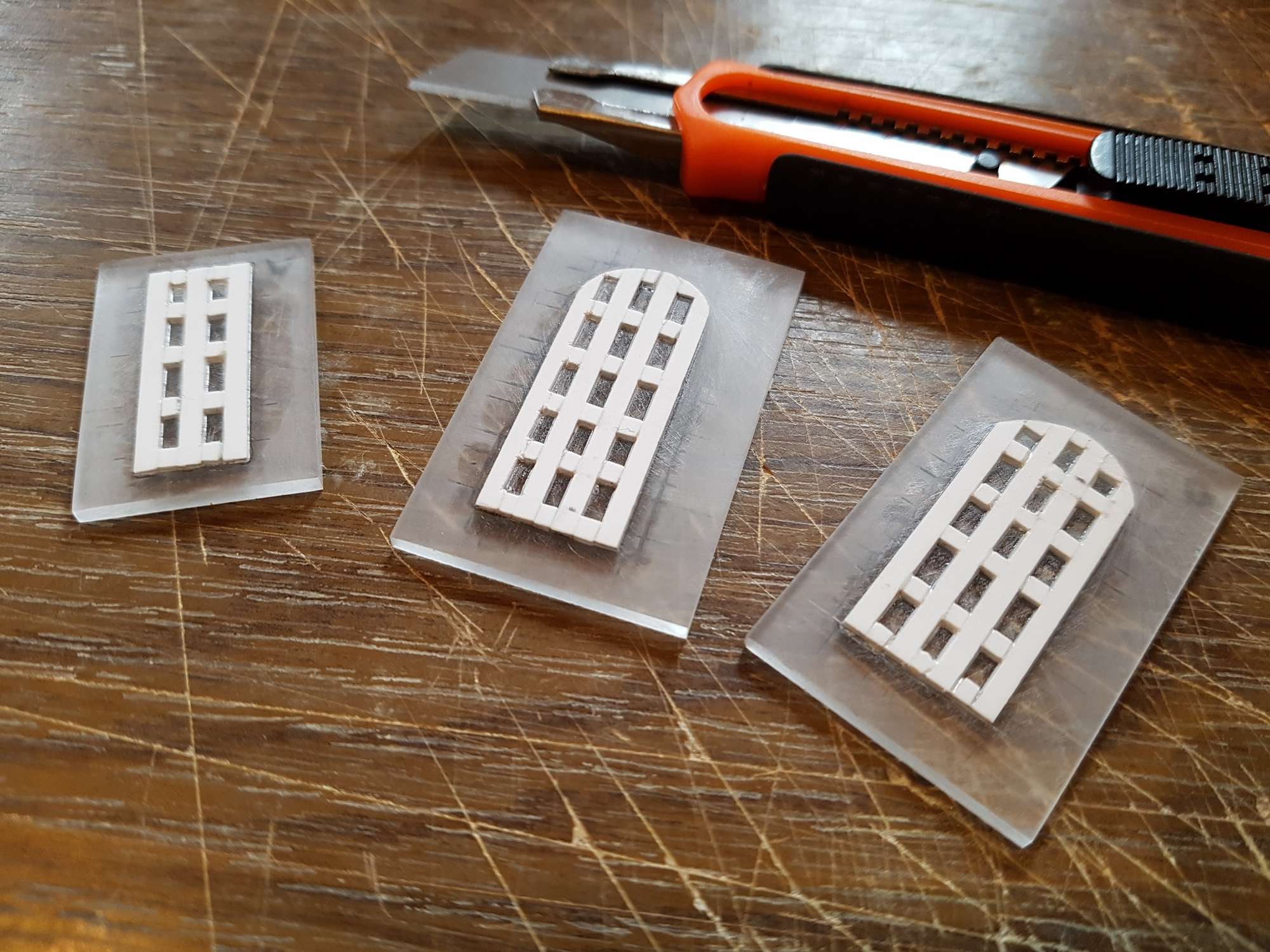

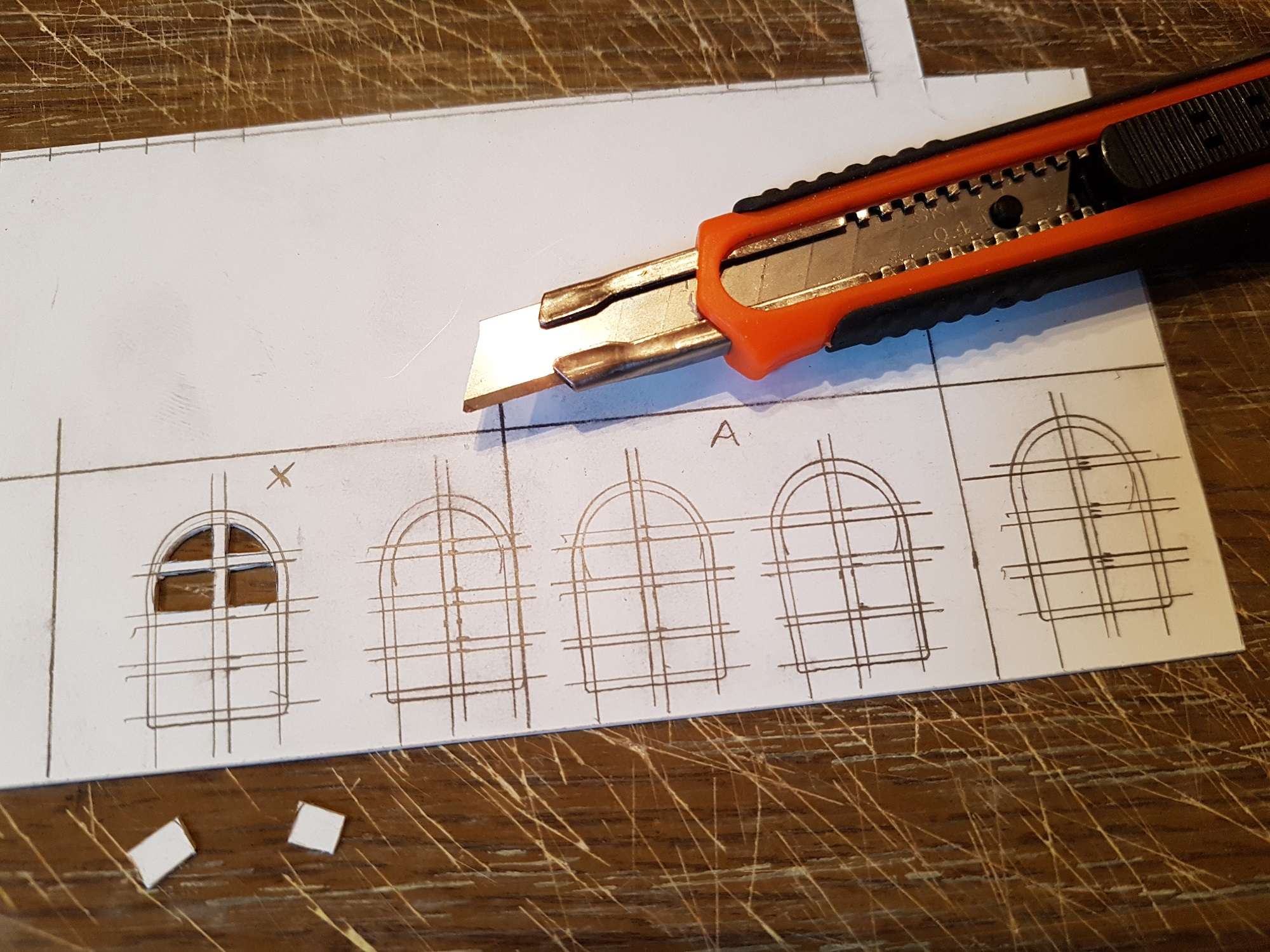

To dig the emplacement of windows and door I need the milling machine as you can see on photos, and finished by a hand file. Next come the brick effect with a pyrographer to print the relief. A soldering iron is doing as well the job. I’ve also engraved some white stripes according to the plan.

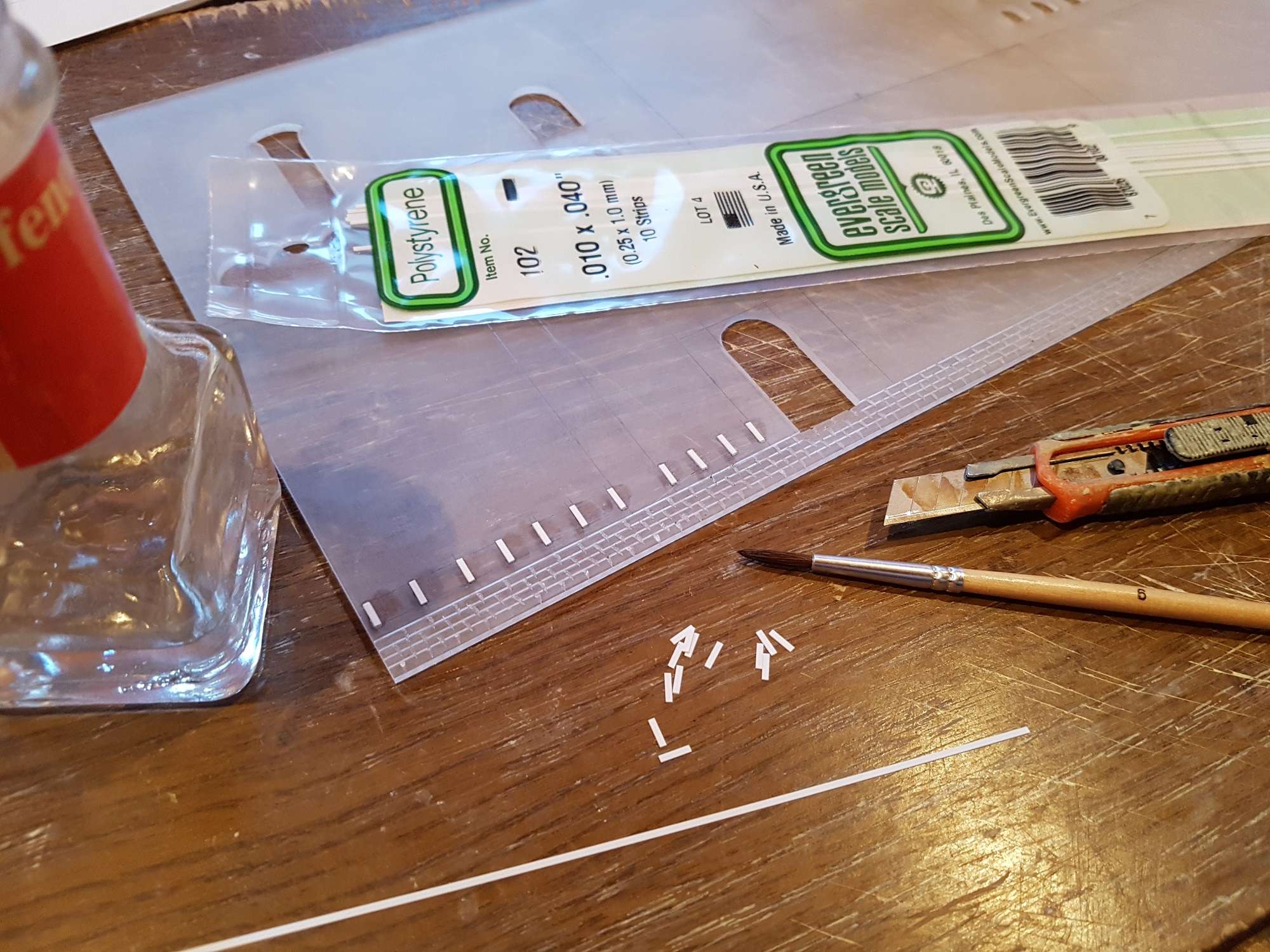

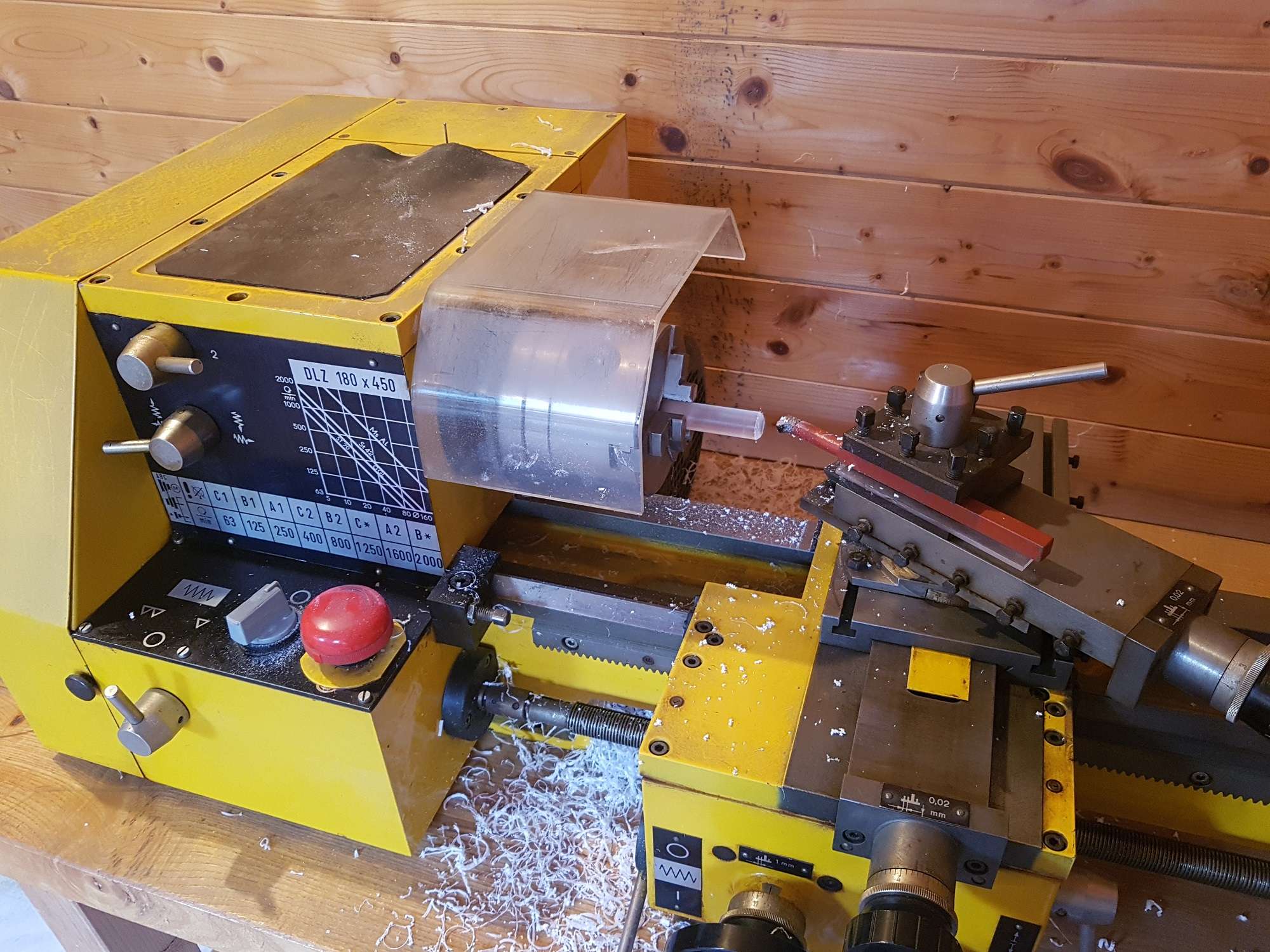

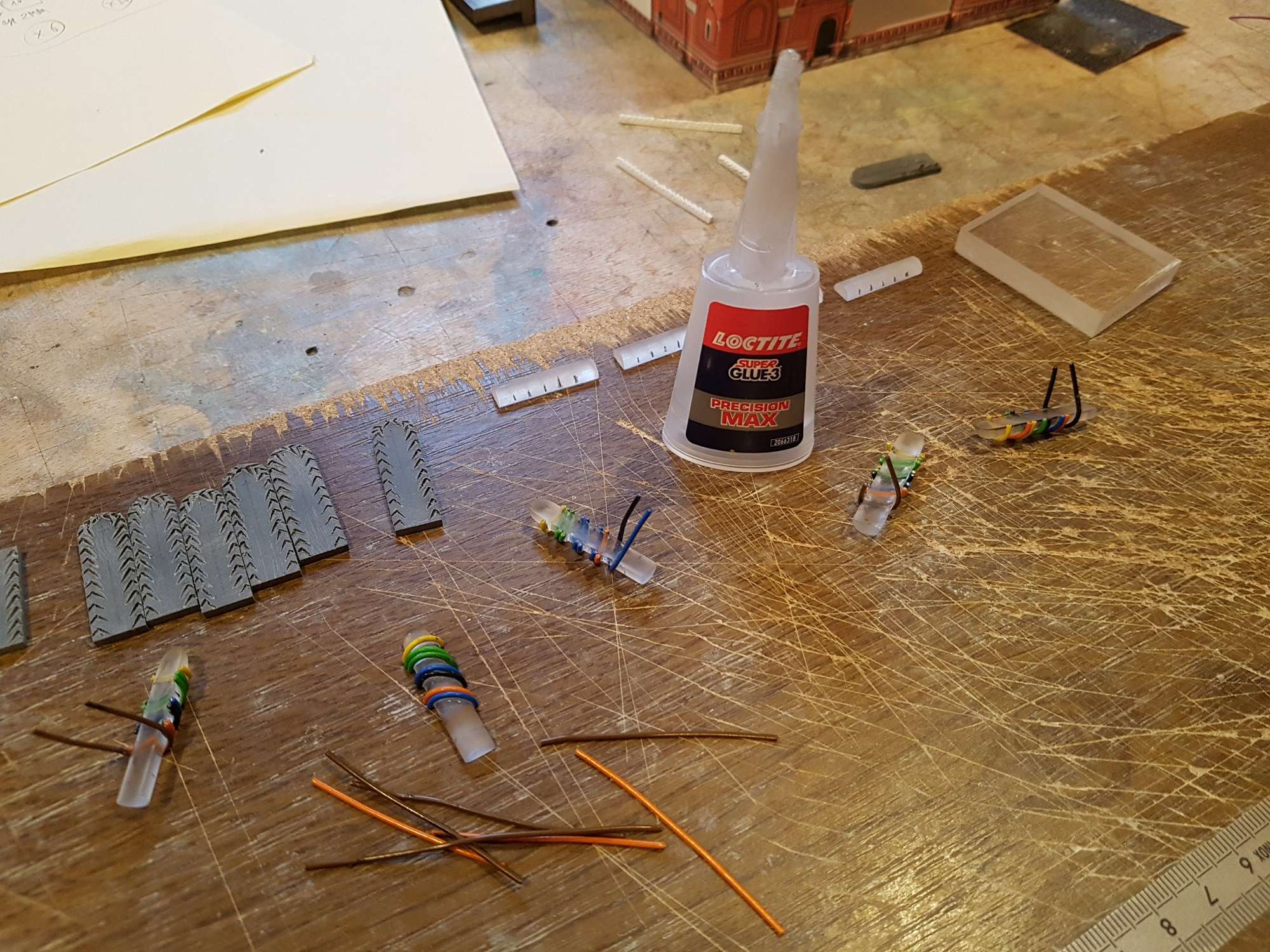

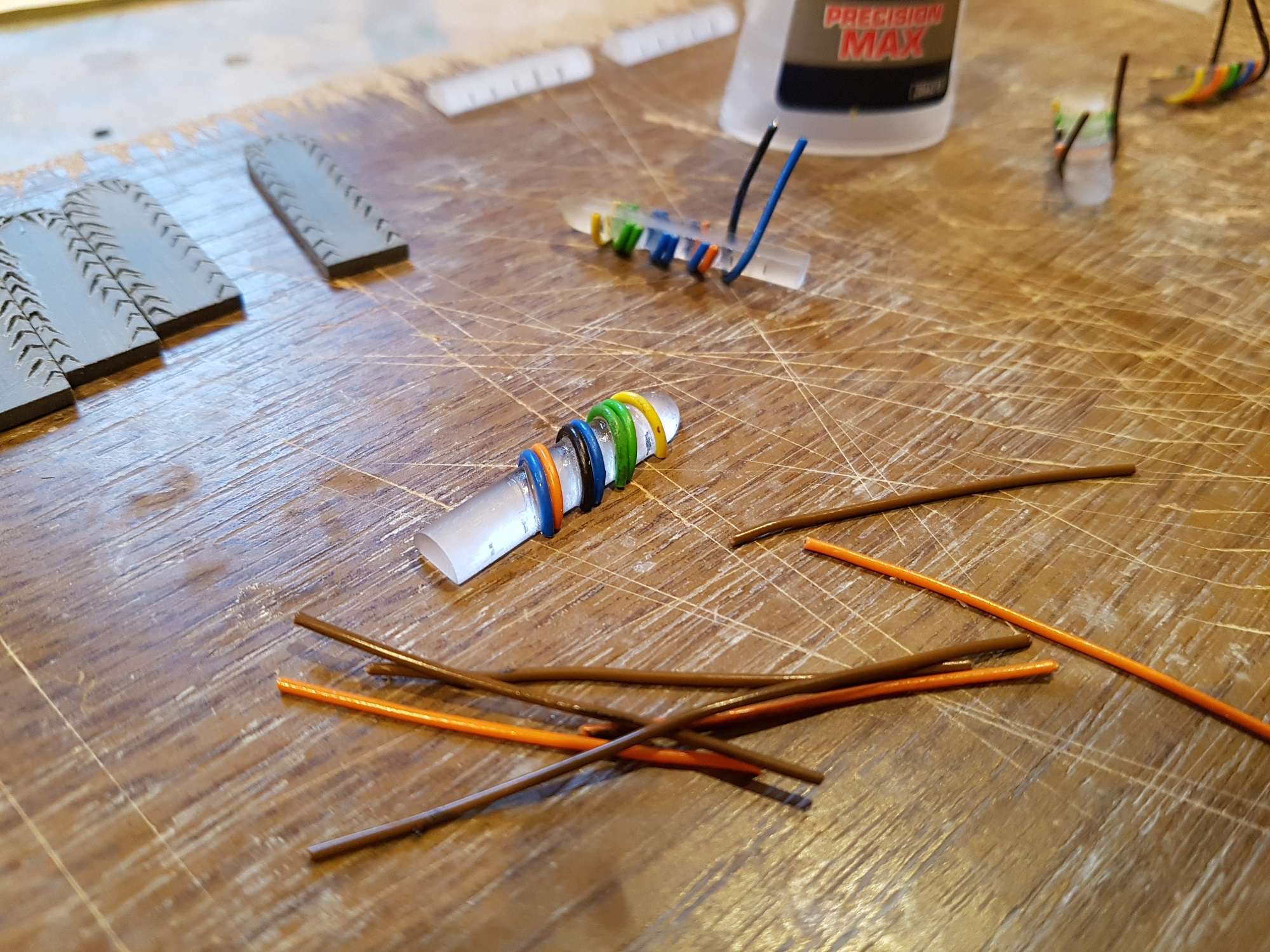

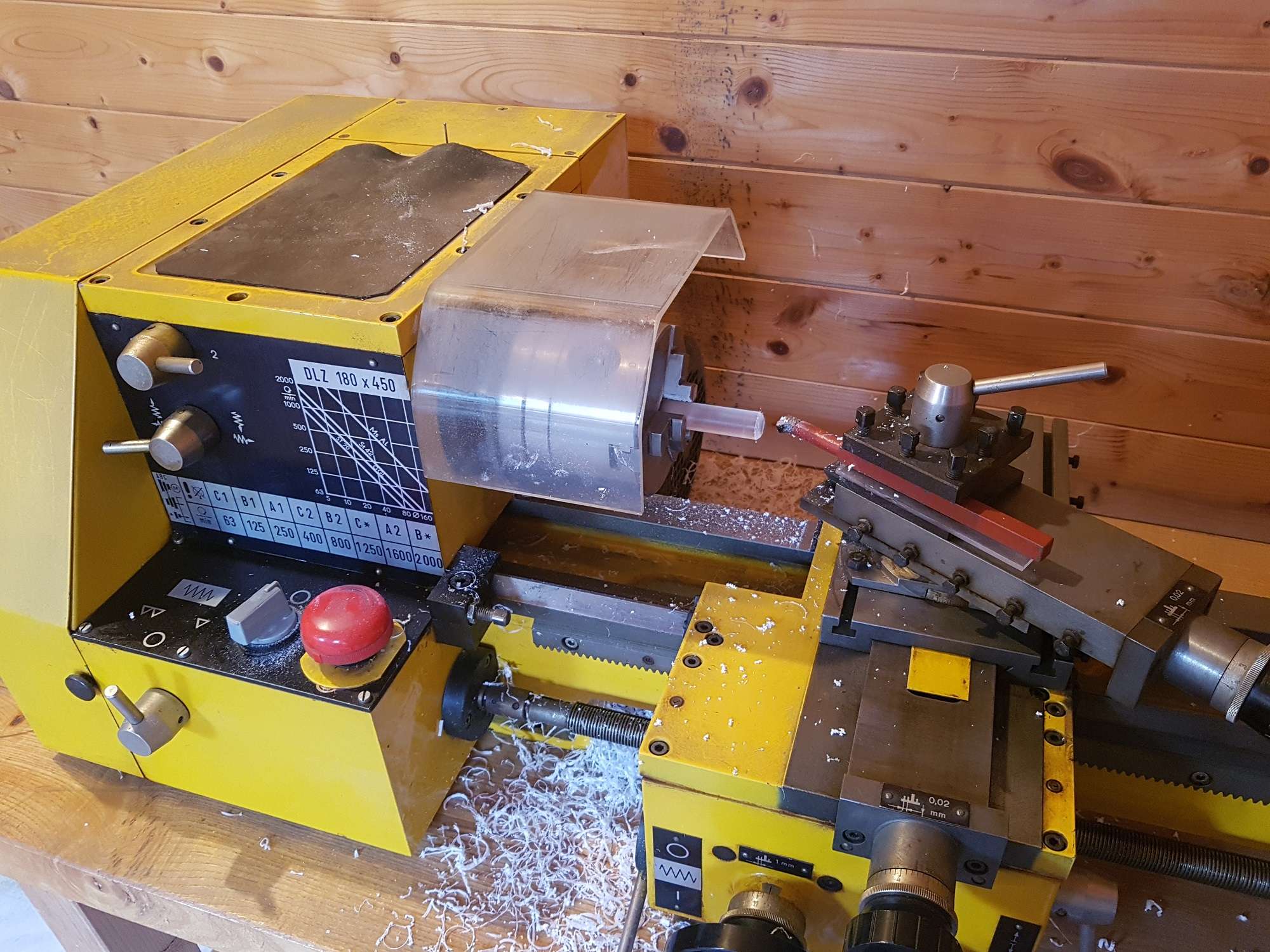

To make the columns I rely on the only tool able to make perfect round shape: a metal lathe, already used for the wood cuppolas. Plenty of details are made with very thin PVC sheet and stripes (many from Evergreen), much more easy to cut, bend and sand by hand.

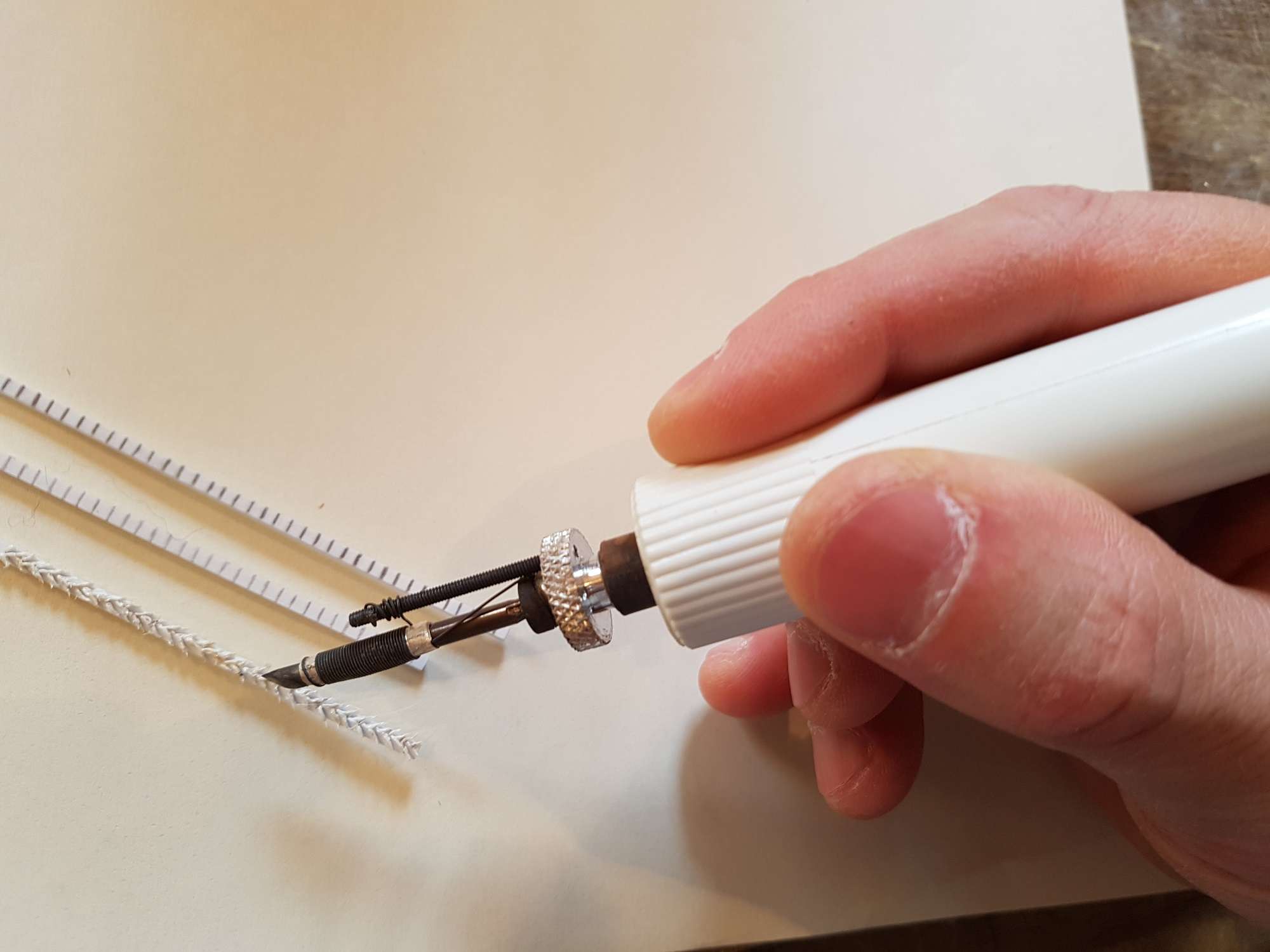

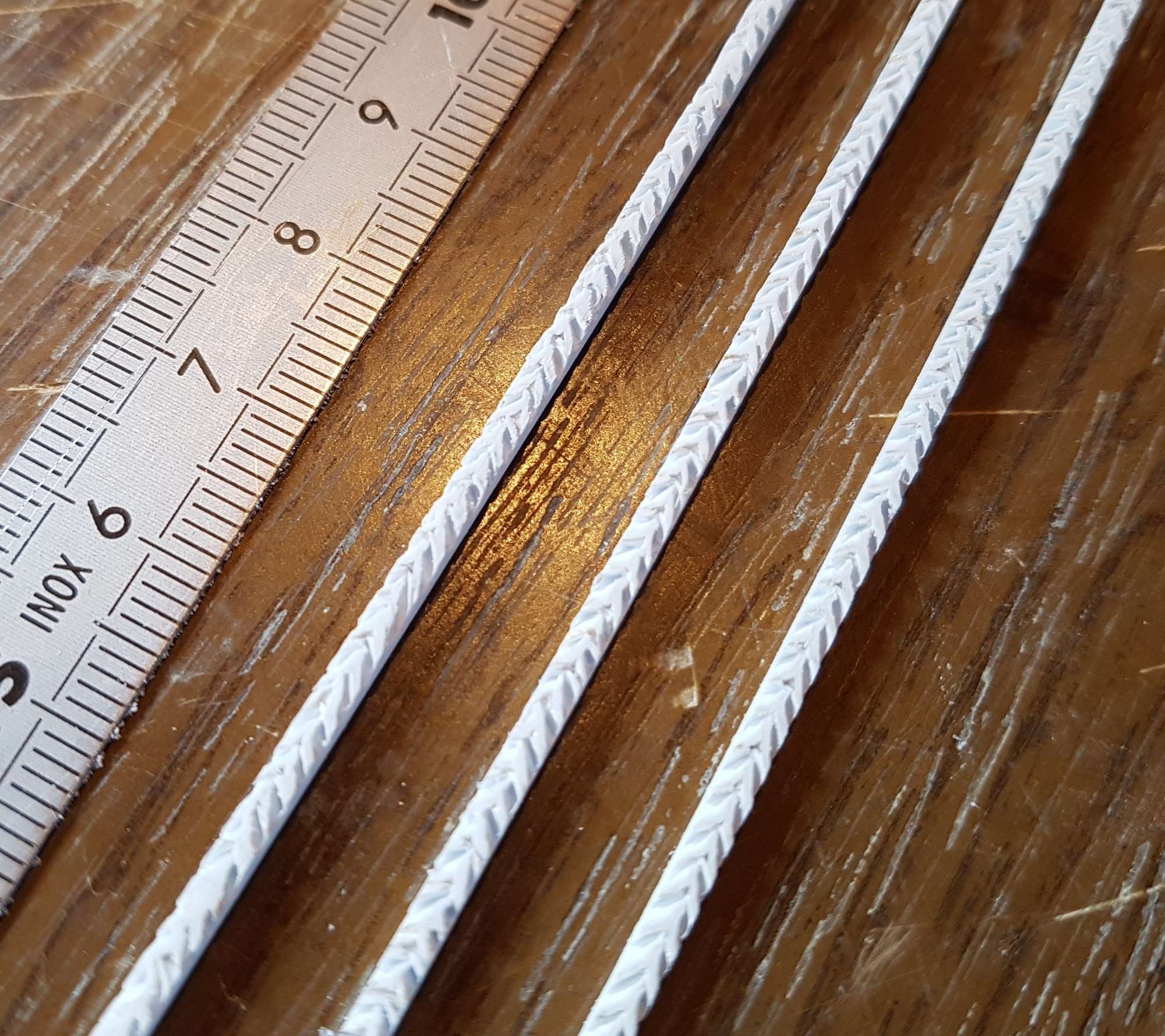

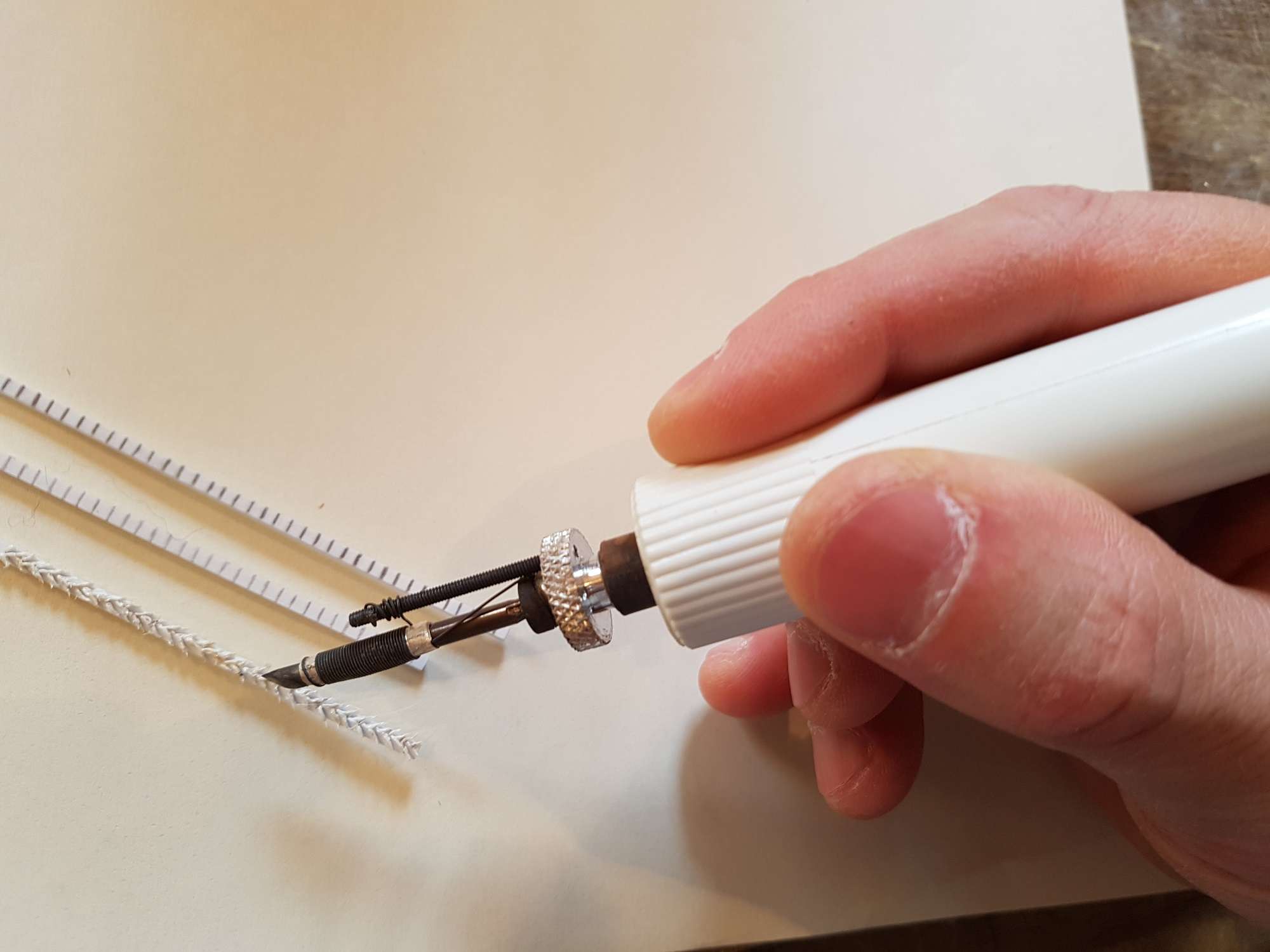

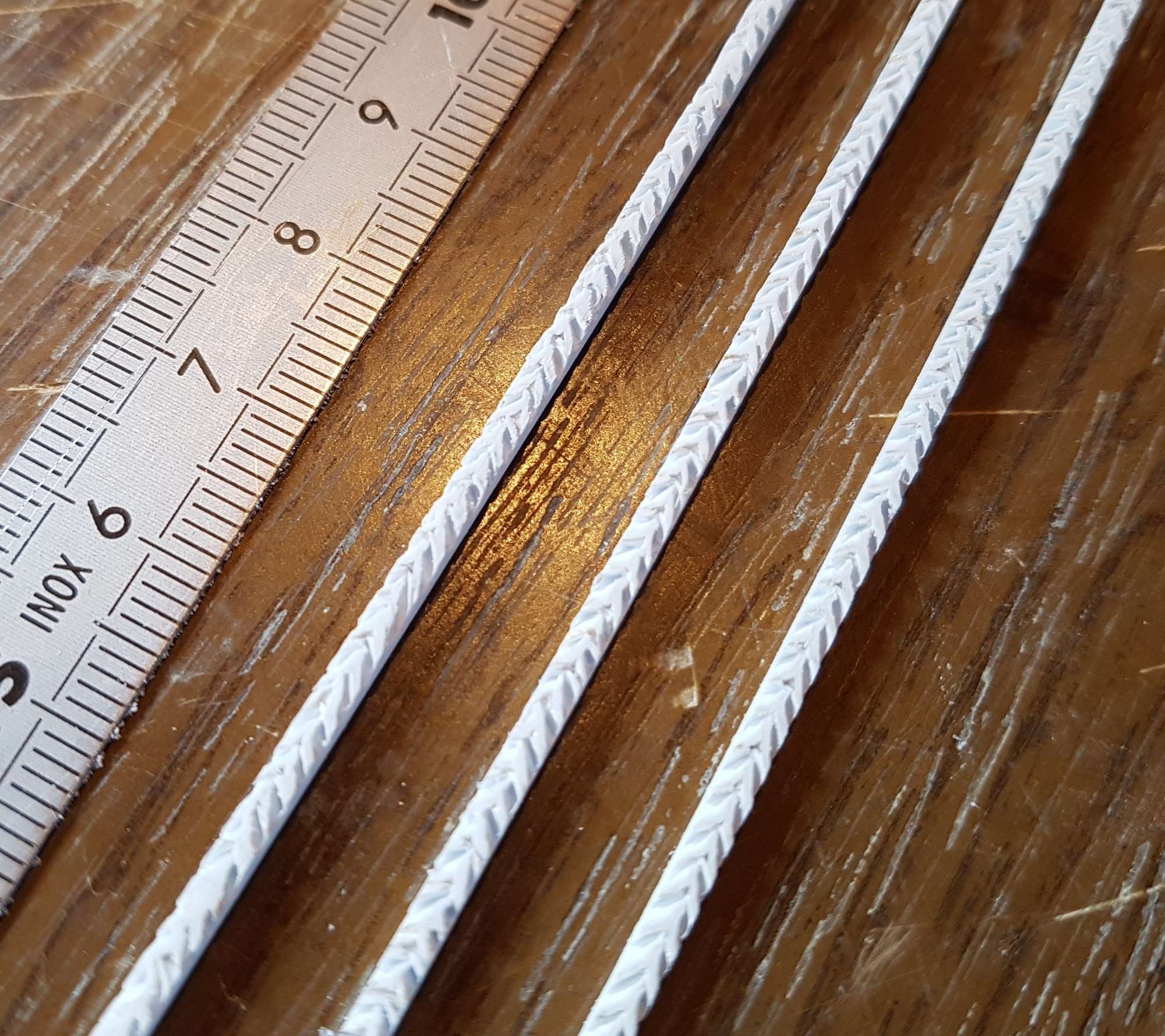

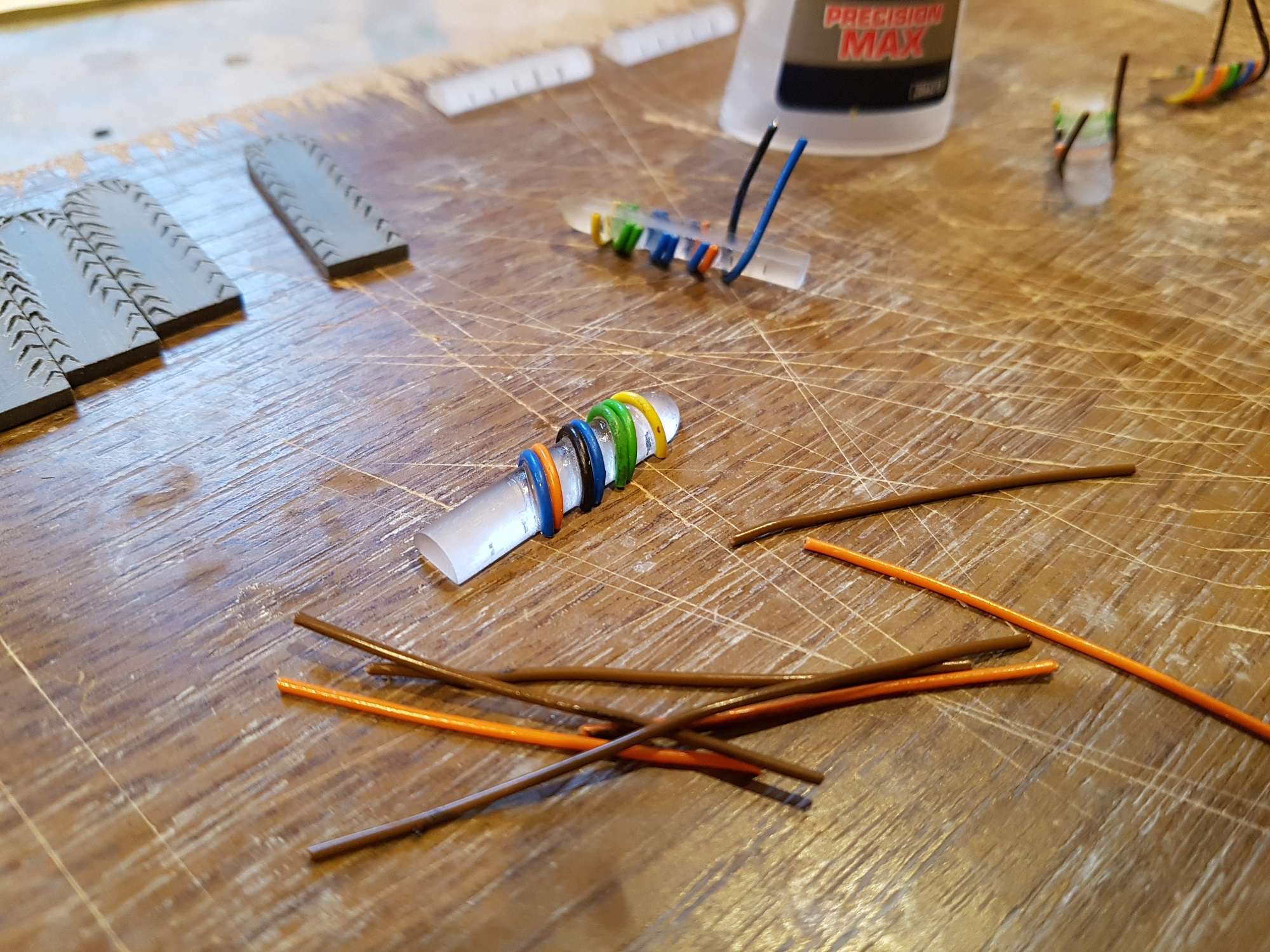

Electric wire joined the project because it suited perfectly what I was looking for, to build all those curious and interesting shapes.

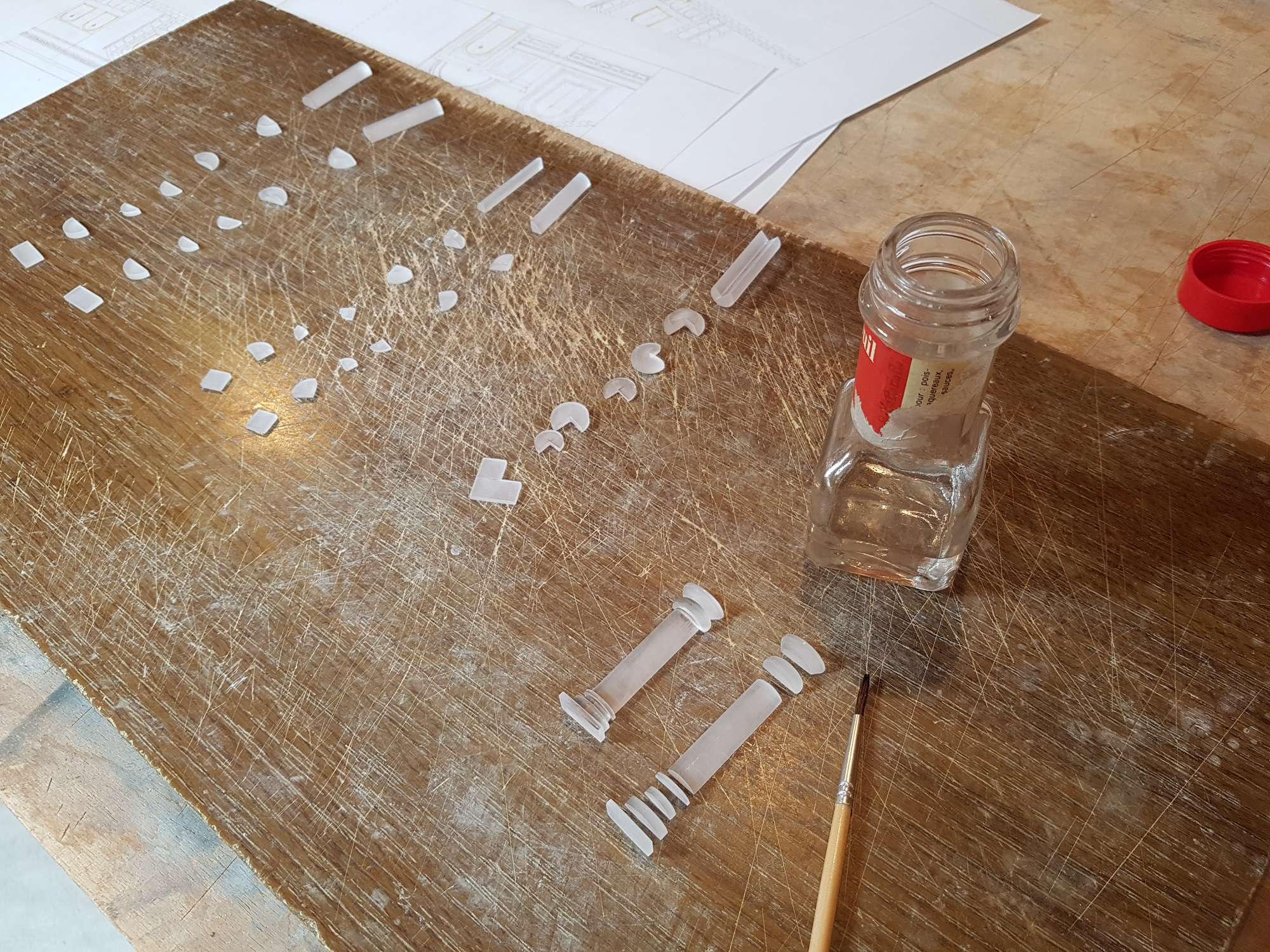

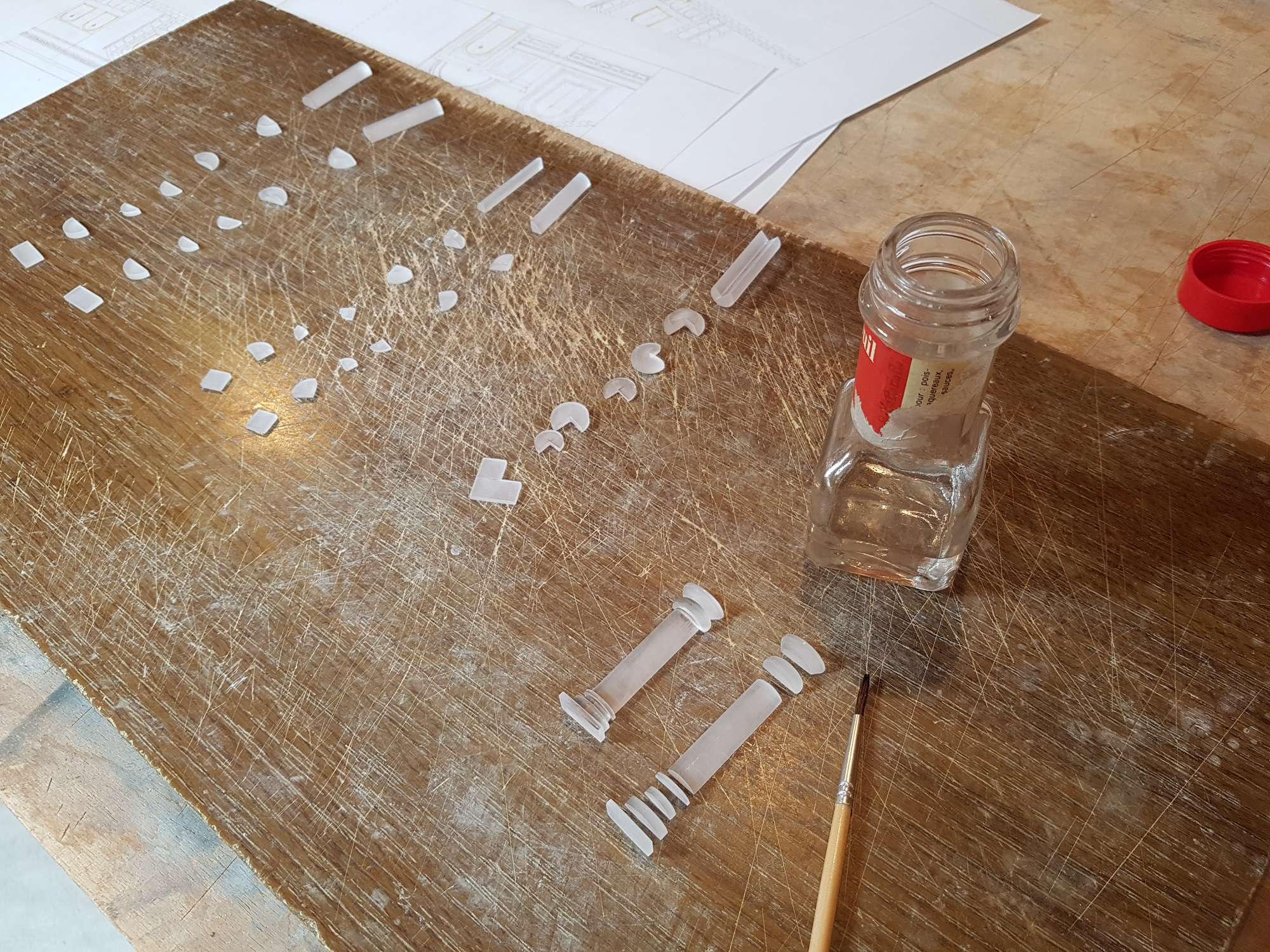

To glue the plexiglass, the best solution is chloroform (applied with a brush)

it’s liquid like water, the extra glue left around the parts immediately evaporate without leaving stain or altering the plastic, and its’ strong like the parts glued were made in one piece! And no bad smell although it’s recommended to aerate the room. This glue is difficult to find but precious !

Next step will be the Cannes film festival in may !

And I'm dedicating this project to the brave people of Ukraine !

Moderator

Moderator

Supporting Member (Bronze)

Supporting Member (Bronze)

Moderator

Moderator Supporting Member (Bronze)

Supporting Member (Bronze)

Supporting Member (Gold)

Supporting Member (Gold)

Supporting Member (Gold)

Supporting Member (Gold)